Section 06

ENGINE MANAGEMENT (DI)

Subsection 03

(COMPONENT INSPECTION AND ADJUSTMENT)

SMR2002-030 _06_03A.FM

06-03-29

Replacement

Unscrew and remove knock sensor.

Clean contact surface, apply Loctite 243 in thread-

ed hole then install the new knock sensor.

Torque screw to 20 N•m (15 lbf•ft).

CAUTION:

Improper torque might prevent sen-

sor to work properly and lead engine to severe

damage of internal components.

Re-plug connector.

RAVE SOLENOID

A quick check can be done as follows. When en-

gine is being stopped, the RAVE valves will open

and close. This can be heard or seen by carefully

removing the cap and feeling the movement with

a hand.

Another test can be done using the vehicle com-

munication kit (VCK) with the B.U.D.S. software,

using the

Monitoring

section. Start engine and

bring its RPM to approximately 6000 and look at

the RAVE solenoid LED. It should turn on, indicat-

ing the RAVE system is working on the electronic

side. However, pneumatic test still have to be per-

formed to validate the mechanical operation.

Leakage/Voltage Test

NOTE:

The solenoid activates both RAVE valves

at the same time.

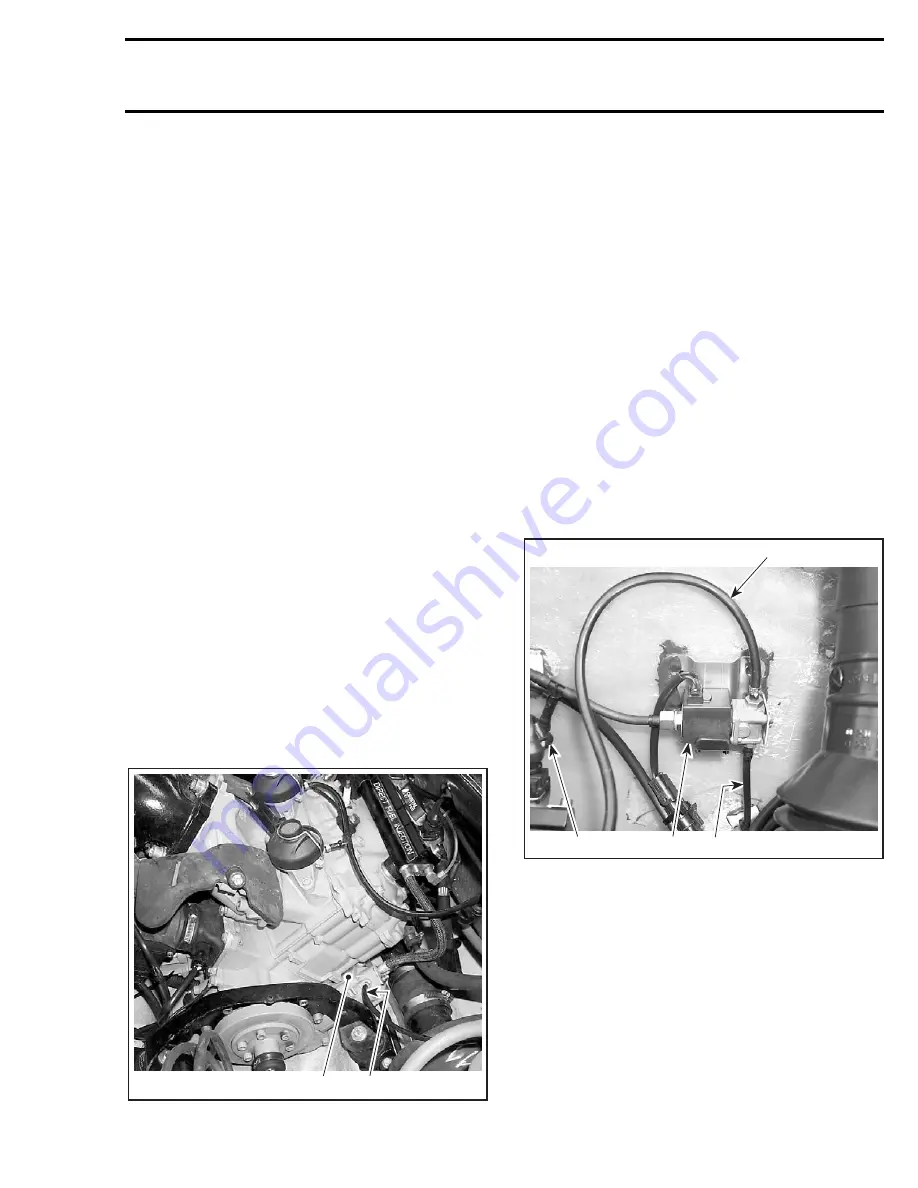

Unplug the RAVE solenoid supply hose from air

compressor.

1. Air compressor

2. Disconnect RAVE supply hose

Install leak test pump (P/N 529 021 800) on hose end

and pressurize air line to 69 - 103 kPa (10 - 15 PSI).

Wait some time to see if pressure drops. If so,

check line for leaks. Otherwise, the solenoid is de-

fective and needs to be replaced.

Using the vehicle communication kit (VCK) with

the B.U.D.S. software, energize the RAVE sole-

noid from the

Activation

section.

The pressure should drop when the solenoid is ac-

tivated. If the solenoid does not work, disconnect

the plug connector from the solenoid.

Install a temporary connector to the solenoid with

wires long enough to make the connection out-

side the bilge and apply voltage (12 V) to this test

harness.

If it does not work, replace the solenoid. Other-

wise, proceed with the resistance test below.

Reconnect hose to compressor.

Unplug the outlet hose from RAVE solenoid.

1. RAVE solenoid

2. Supply hose from air compressor

3. Check valve

4. Outlet hose to RAVE valves

Install leak test pump on hose end and apply pres-

sure. If pressure can not be held, check hoses for

leaks. If hoses test good, connect pump directly

to each RAVE valve nipple and pressurize. If pres-

sure drops, replace the defective seal inside RAVE

valve.

Take into account that the RAVE may be mechani-

cally stuck in the cylinder slot. Open the RAVE and

check for free operation. Refer to ENGINE and look

in TOP END.

F12R0RA

1

2

1

F12R0TA

2

4

3

www.SeaDooManuals.net

Summary of Contents for GTI 5558

Page 1: ...www SeaDooManuals net ...

Page 2: ...2002 Shop Manual Volume 1 GTI GTI LE GTX GTX RFI XP RX RX DI LRV DI www SeaDooManuals net ...

Page 541: ...2002 GTI MODEL www SeaDooManuals net ...

Page 542: ...SMR2002 051_16_00A FM 2002 GTI MODEL F17Z01 www SeaDooManuals net ...

Page 543: ...2002 GTI LE MODEL www SeaDooManuals net ...

Page 544: ...SMR2002 051_16_00A FM 2002 GTI LE MODEL F11Z02 www SeaDooManuals net ...

Page 545: ...2002 GTX MODEL www SeaDooManuals net ...

Page 546: ...SMR2002 051_16_00A FM 2002 GTX MODEL F07Z01 www SeaDooManuals net ...

Page 547: ...2002 GTX RFI MODEL www SeaDooManuals net ...

Page 548: ...SMR2002 051_16_00A FM 2002 GTX RFI MODEL F15Z04 www SeaDooManuals net ...

Page 549: ...2002 XP MODEL www SeaDooManuals net ...

Page 550: ...SMR2002 051_16_00A FM 2002 XP MODEL F08Z02 www SeaDooManuals net ...

Page 551: ...2002 RX MODEL www SeaDooManuals net ...

Page 552: ...SMR2002 051_16_00A FM 2002 RX MODEL F16Z03 www SeaDooManuals net ...

Page 553: ...2002 RX DI MODEL www SeaDooManuals net ...

Page 554: ...SMR2002 051_16_00A FM 2002 RX DI MODEL F16Z04 www SeaDooManuals net ...

Page 555: ...2002 LRV DI MODEL www SeaDooManuals net ...

Page 557: ...www SeaDooManuals net ...