Section 09

LUBRICATION SYSTEM

Subsection 03

(OIL INJECTION PUMP)

09-03-10

SMR2002-037_09_03A.FM

Check small oil lines of pump. They must be full

of oil.

1. Lines must be full of oil

2. Oil pump

If not, proceed as follows.

All Models except DI

Run engine at idle speed while manually holding

pump lever in fully open position. Do not activate

throttle lever.

DI Models

– Use the VCK (Vehicle Communication Kit) P/N

529 035 676. Look in the MONITORING section

of the software B.U.D.S.

– Use the “Oil lines bleeding” function that al-

lows to “lock” the engine RPM in idle speed

while the throttle is fully depressed to ease the

bleeding operation.

– Since oil cannot be seen through the small oil

lines, press and hold the vehicle throttle to wide

open position for 45 seconds.

All Models

CAUTION:

If watercraft is out of water, engine

must be cooled using the flush kit.

CHECKING OPERATION

On Watercraft

NOTE:

Oil line supply must be full of oil. See

bleeding procedure above.

Start engine and run at idle while holding the pump

lever in fully open position. Oil must advance into

small oil lines.

NOTE:

The engine should have a rich mixture,

idling irregularly and emitting smoke at exhaust

outlet.

If not, remove pump assembly and check the

pump gear (717 engine) or shaft (787 RFI and 947

engines) for defects, replace as necessary. Test

pump as described below:

NOTE:

Through normal use, oil level must not

drop in small tubes. If oil drops, verify check valve

operation. Replace as necessary.

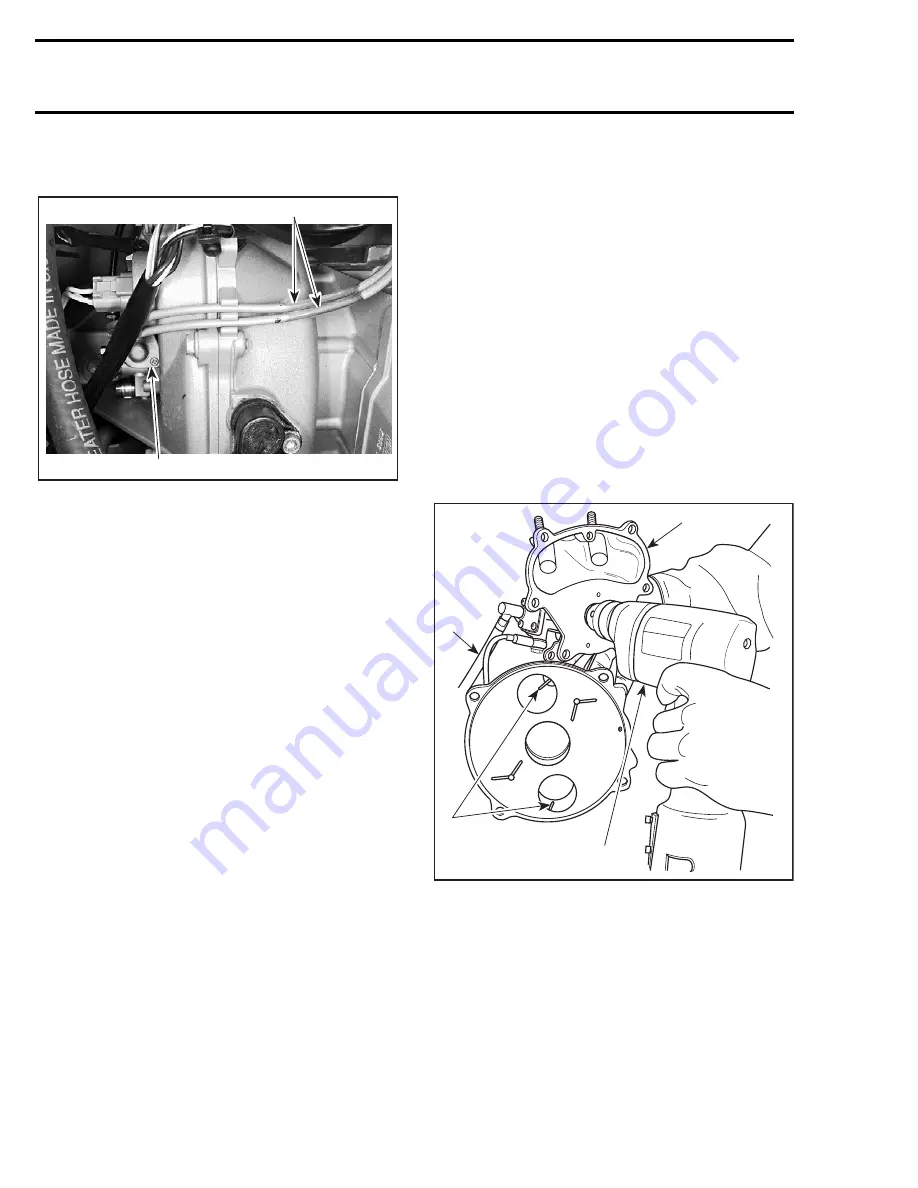

Bench Test

Connect a hose filled with injection oil to main line

fitting. Insert other hose end in an injection oil con-

tainer. Using a counterclockwise (reverse position)

rotating drill rotate pump shaft. Oil must drip from

fittings in parts of rotary valve cover while holding

lever in a fully open position.

TYPICAL

1. Supply oil line to an oil container

2. Hold lever in fully open position

3. Counterclockwise (reverse) rotating drill

4. Oil must drip here

For an accurate test, each port should be checked

separately to ensure equal delivery on both ports.

To obtain a precise result of the oil pump delivery

rate, rotate it counterclockwise at 1500 RPM for a

total time of 5 minutes.

NOTE:

To ensure accuracy of test, oil lines should

be completely filled before starting test.

1

2

F07G06A

F01G02A

1

2

3

4

www.SeaDooManuals.net

Summary of Contents for GTI 5558

Page 1: ...www SeaDooManuals net ...

Page 2: ...2002 Shop Manual Volume 1 GTI GTI LE GTX GTX RFI XP RX RX DI LRV DI www SeaDooManuals net ...

Page 541: ...2002 GTI MODEL www SeaDooManuals net ...

Page 542: ...SMR2002 051_16_00A FM 2002 GTI MODEL F17Z01 www SeaDooManuals net ...

Page 543: ...2002 GTI LE MODEL www SeaDooManuals net ...

Page 544: ...SMR2002 051_16_00A FM 2002 GTI LE MODEL F11Z02 www SeaDooManuals net ...

Page 545: ...2002 GTX MODEL www SeaDooManuals net ...

Page 546: ...SMR2002 051_16_00A FM 2002 GTX MODEL F07Z01 www SeaDooManuals net ...

Page 547: ...2002 GTX RFI MODEL www SeaDooManuals net ...

Page 548: ...SMR2002 051_16_00A FM 2002 GTX RFI MODEL F15Z04 www SeaDooManuals net ...

Page 549: ...2002 XP MODEL www SeaDooManuals net ...

Page 550: ...SMR2002 051_16_00A FM 2002 XP MODEL F08Z02 www SeaDooManuals net ...

Page 551: ...2002 RX MODEL www SeaDooManuals net ...

Page 552: ...SMR2002 051_16_00A FM 2002 RX MODEL F16Z03 www SeaDooManuals net ...

Page 553: ...2002 RX DI MODEL www SeaDooManuals net ...

Page 554: ...SMR2002 051_16_00A FM 2002 RX DI MODEL F16Z04 www SeaDooManuals net ...

Page 555: ...2002 LRV DI MODEL www SeaDooManuals net ...

Page 557: ...www SeaDooManuals net ...