Page 4 of 11

123-652 Rev -

3.3.1

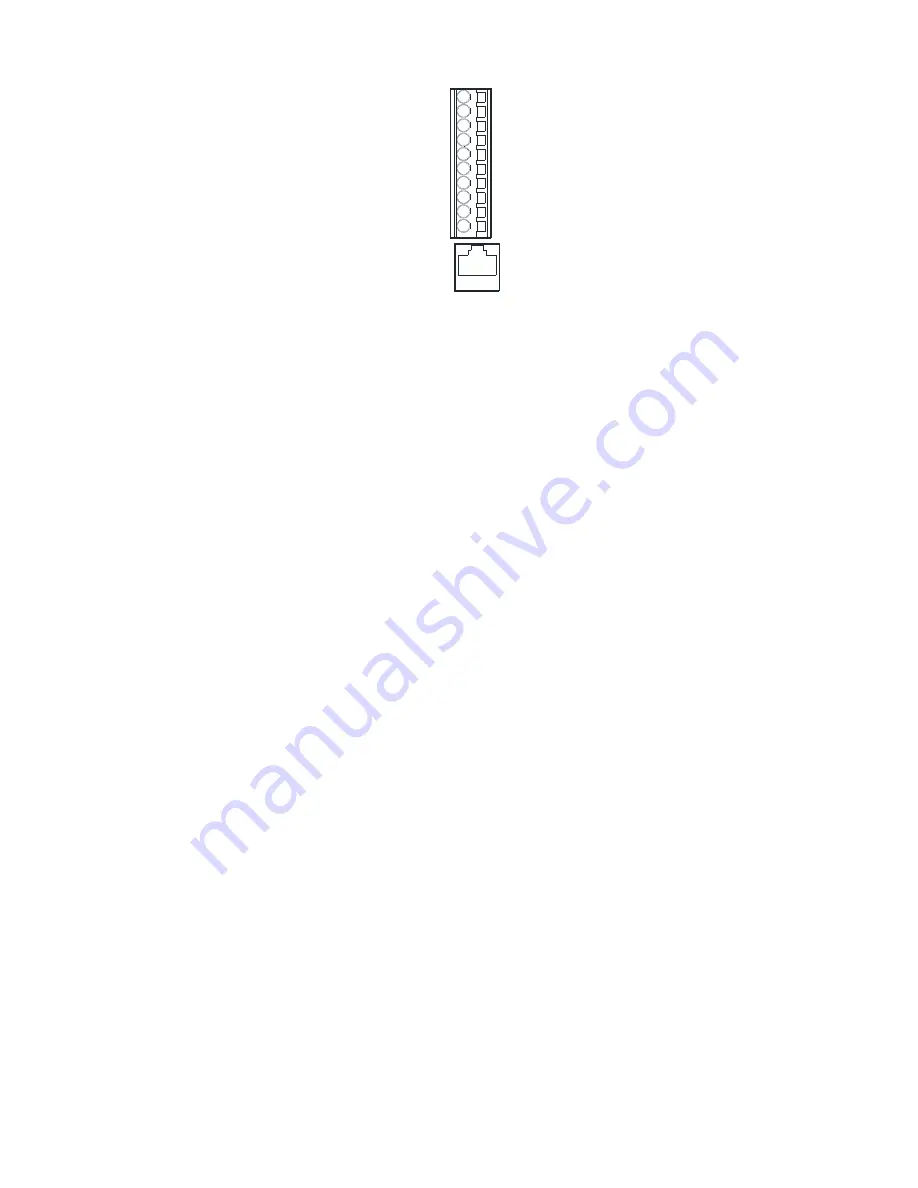

ELECTRICAL INPUT/OUTPUT CONNECTIONS

1

2

3

4

VIN1 +

VIN1 -

VIN2 +

VIN2 -

VIN3 +

VIN3 -

DISPLAY

PANEL

Figure 2: Input/output Terminal Block

3.3.1.1

MSRS Pressure Switch (PS1) Terminals 1 and 2 connection

Install one of the wires from the Cylinder Low-Pressure Switch or from the Discharge Pressure Switch to

the terminals marked “1” and the other wire to the terminal marked “2”. See Figure 2.

3.3.1.2

MSRS Pressure Switch (PS2) Terminals 3 and 4 connection

The MSRS unit has a wire jumper installed across PS2 terminals from the factory. If the MSRS PS2

terminals are being used, remove the wire jumper. Leave the wire jumper in-place if the PS2 terminals are

not being used.

Install one of the wires from the High Temp Sensor or the Cylinder Low-Pressure Supervisory Switch to the

terminal marked “3” and the other wire to the terminal marked “4”. See Figure 2.

o

Low-Pressure Switch/Auxiliary Cylinder Supervisory Switch - When the pressure in the cylinder drops

to an unserviceable (low) pressure, the switch shall open activating the early warning alarm.

o

Temperature Sensor – When the temperature in the protected zone goes above the fixed temperature

of the sensor, the sensor shall open activating the early warning alarm.

3.3.1.3

Power Supply Terminals – Main Supply, Backup Supply, and Generator

The MSRS Unit has 3 diode-protected inputs but only one power source is needed to operate the MSRS

and should be connected to V IN1+ and V IN1-. See Figure 2.

o

If available, a backup power source should be connected to one of the additional power source inputs.

Connect the MSRS unit to the power source(s) using a 5A circuit breaker with an ON/OFF switch. Use the

breaker switch to turn the MSRS Unit OFF when all the machinery is OFF and to turn the MSRS Unit ON if

any machinery is ON.

3.3.1.4

RJ45 Port

The RJ45 socket connects the Display Panel to the MSRS unit via a supplied CAT-5 cable. Install one end of

the CAT-5 cable into the MSRS unit RJ45 socket and the other end into one of the Display Panel RJ45

socket.

o

Connect Multiple Display Panels to the MSRS unit by using the available RJ45 socket on the back of the

Display Panel.

Check the Display Panel Installation Manual on how to correctly connect and use the Display Panel.

Summary of Contents for 131-740

Page 11: ...Page 11 of 11 123 652 Rev ...