Page 5 of 11

123-652 Rev -

Compatible Display Panels: “Fire Suppression System Monitor and Engine Shutdown Control”

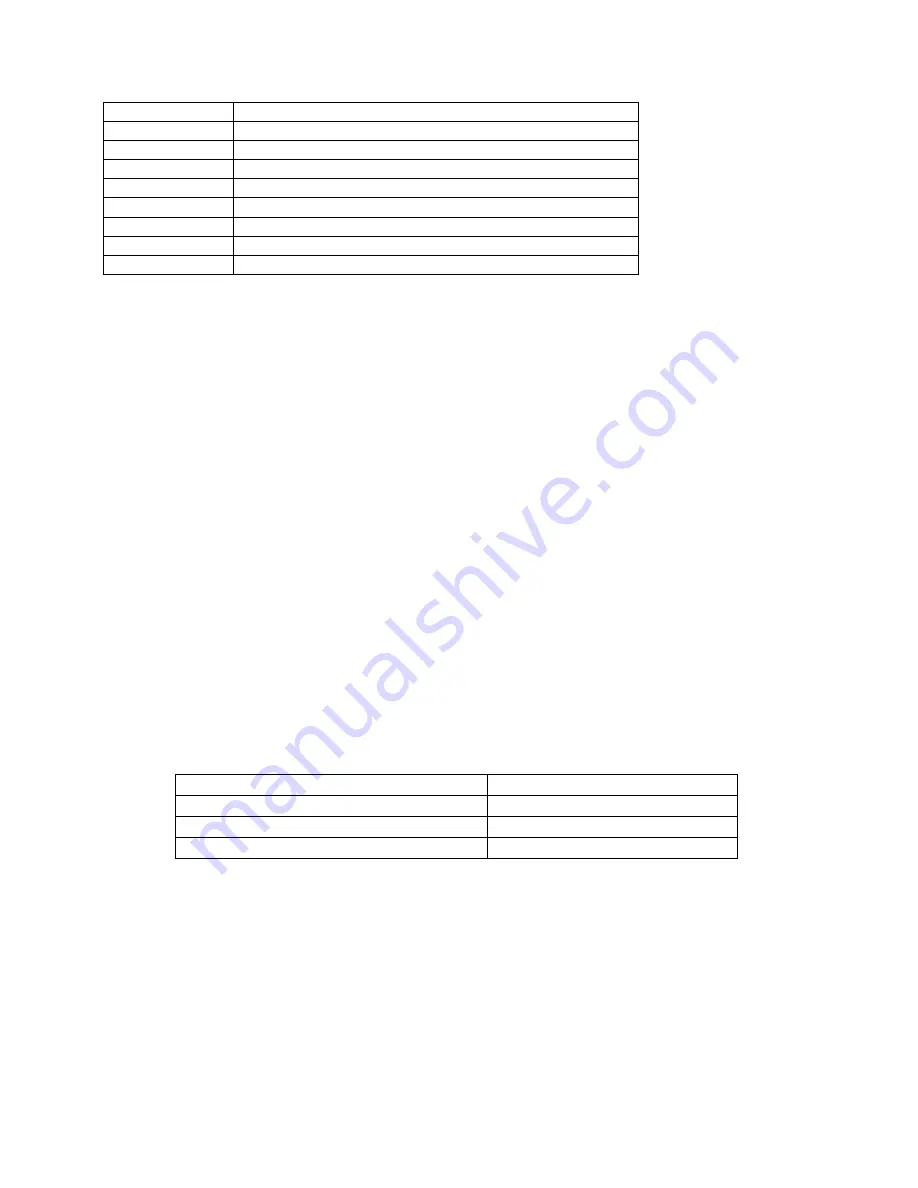

Part Number

Display Panel indicators and shape

131-460

Power and Discharge Indication, Rectangle

131-461

Power and Discharge Indication, Round

131-462

Power, Discharge, and High Temp Indication, Rectangle

131-463

Power, Discharge, and High Temp Indication, Round

131-464

Power, Discharge, and Aux Zone Indication, Rectangle

131-465

Power, Discharge, and Aux Zone Indication, Round

131-466

Power, Discharge, and Low-Pressure Indication, Rectangle

131-467

Power, Discharge, and Low-Pressure Indication, Round

3.3.1.5

Multiple Cylinder Supervisory Switch Connection to the MSRS PS1

When connecting more than one pre-engineered cylinder supervisory pressure switch to the MSRS Unit,

connect all the supervisory pressure switches in series. Connect the leading switch wire to Terminal

marked “1” and the trailing wire of the last pressure switch to Terminal marked “2” (See Figure 2).

When connecting more than one Engineered System cylinder supervisory switch to the MSRS unit, connect

all the cylinder supervisory switches in series. Connect the leading switch wire to Terminal marked “3”

and the trailing wire of the last pressure switch to Terminal marked “4” (See Figure 2).

When connecting more than one Engineered System discharge pressure switch, reference the engineered

fire suppression manual and electrical circuit diagram provided as part of the system.

3.3.1.6

Engine or Machinery connection

Refer to the Original Equipment Manufacturers (OEM) Engine or the machinery Installation manual for the

correct method of connection to relays of the MSRS unit. Equipment manufacturers have a variety of

methods to control their equipment.

The following section provides the basic operation of the relays in the MSRS unit.

4

Relay Operation:

This section provides the basic operation of the relays in the ESRS unit.

4.1.

Relay Contact Specification

Table 1 Relay Contact Specification

Item

Value

Contact

SPDT (1 Form C)

Contact Current

10A NC / 20A NO

Contact Voltage VAC (Maximum allowable) 277VAC

N/C – Normally Closed Contact

N/O – Normally Open Contact

COM – Common Terminal

4.2.

Relay De-Energized State

When the MSRS is operational and in the standby mode, all the relays should be in the de-energized state.

The N/C and the COM terminals are connected.

The N/O terminal is open.

Summary of Contents for 131-740

Page 11: ...Page 11 of 11 123 652 Rev ...