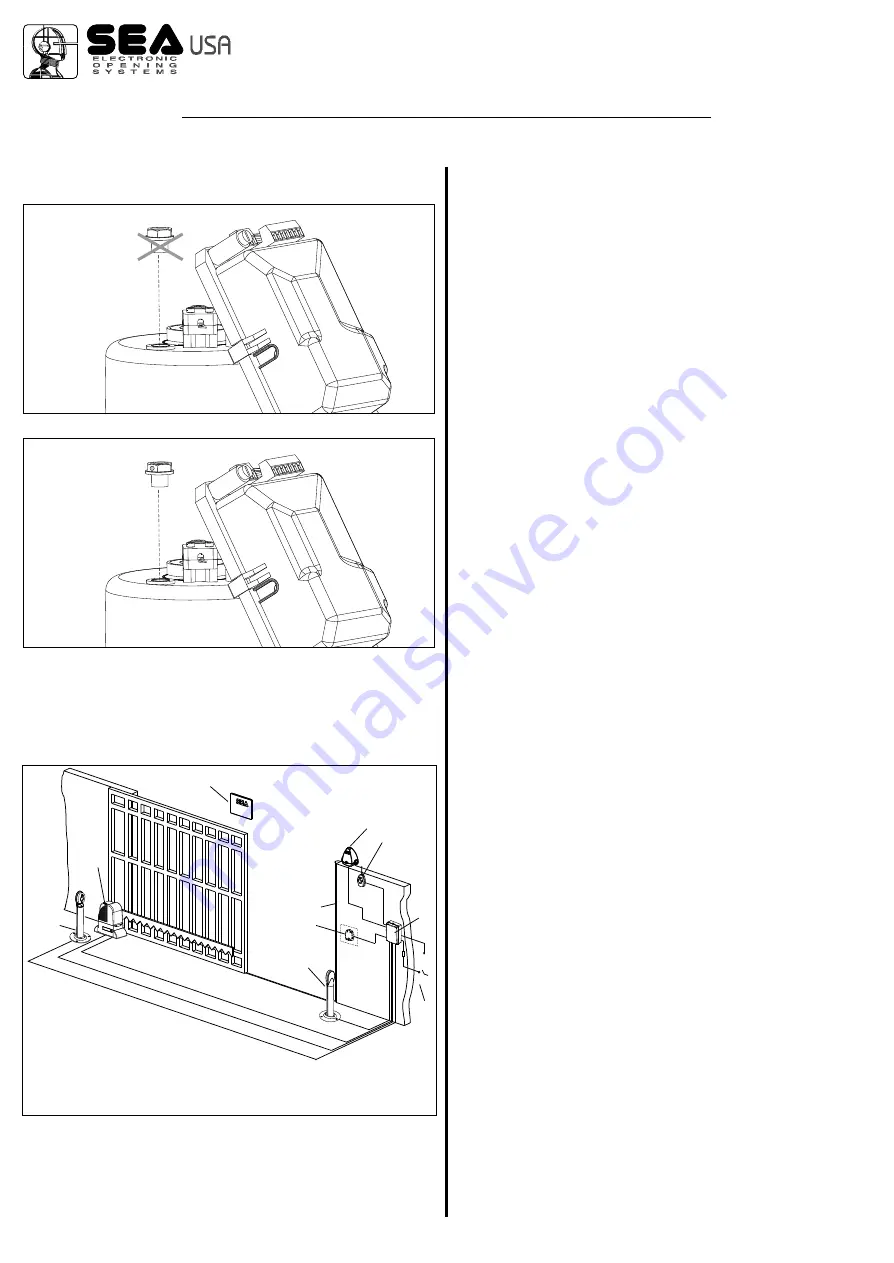

Fig. 36

Fig. 37

1

2

3

4

10

5

6

7

8

9

Fig. 38

13. BREATHER SCREW REPLACEMENT

Replace the breather screw before startup.

14.

(Fig. 38)

CABLE LAYOUT

1) LEPUS operator

2) Left photocell

3) Right photocell

4) Pneumatic safety edge

5) Key switch

6) Flashing warning lamp

7) Radio receiver

8) Warning notice

9) Electronic control unit or j

10) Differential switch

unction box

Cod. 67410022

REV 00 - 12/2013

®

International registered trademark n. 2.777.971

MECHANICAL INSTALLATION

10