Cod. 67410022

115 V (±5%) 50/60 Hz

350W

70

60%

1550 rpm

1/30

-4°F +131°F

130°C

33 pound

1,75 L.

IP 55

0,65 feet/s

0,75 feet /s

60 Nm

1000 Kg / 2204,62 pound

~

µF

Mechanical in oil bath - Electronic

Mechanical with leve/Inductive

LEPUS 1000 110V

1000 Kg

2204,62 pound

L

E

P

U

S

1

0

0

0

1

1

0

V

60%

TECHNICAL DATA

Power Supply

Power

Motor rotation speed

Reduction ratio

Room temperature

Thermal protection intervention

Weight of the unit with oil

Oil quantity

Protection rating

Gate speed (pinion Z16)

Gate speed (pinion Z20)

Maximum weight of the gate

Limit switch

Motor capacitor

Working frequency

Maximum torque

Anti- crushing clutch

Note

: The frequency of use is valid only for the first hour at 68°F room

temperature.

LEPUS MOTOR-REDUCER USING-GRAPHIC

F

re

q

u

e

n

c

y

o

f

u

s

e

M

a

x

g

a

te

w

e

ig

h

t

Oil-bathed motor-reducers

REV 00 - 12/2013

L

E

P

U

S

1

0

0

0

1

1

0

V

®

International registered trademark n. 2.777.971

LEPUS

is an

oil-bathed motor-reducer

created for sliding

gates automation. The motor-reducer

irreversibility

allows a

perfect and safe gate closing avoiding the setup of an

electrolock and in case of power supply lacking, the release

device which is in the frontal part of the motor-reducer allows the

manual opening and closing. The operator has a

mechanical

adjustable clutch

which ensures the control of the gate

pushing. Moreover,

the electronic reversing device

realized

through an

encoder

makes the lepus motor-reducer a safe and

reliable operator allowing in a simple way to comply with the

current norms in the countries where this product is set up.

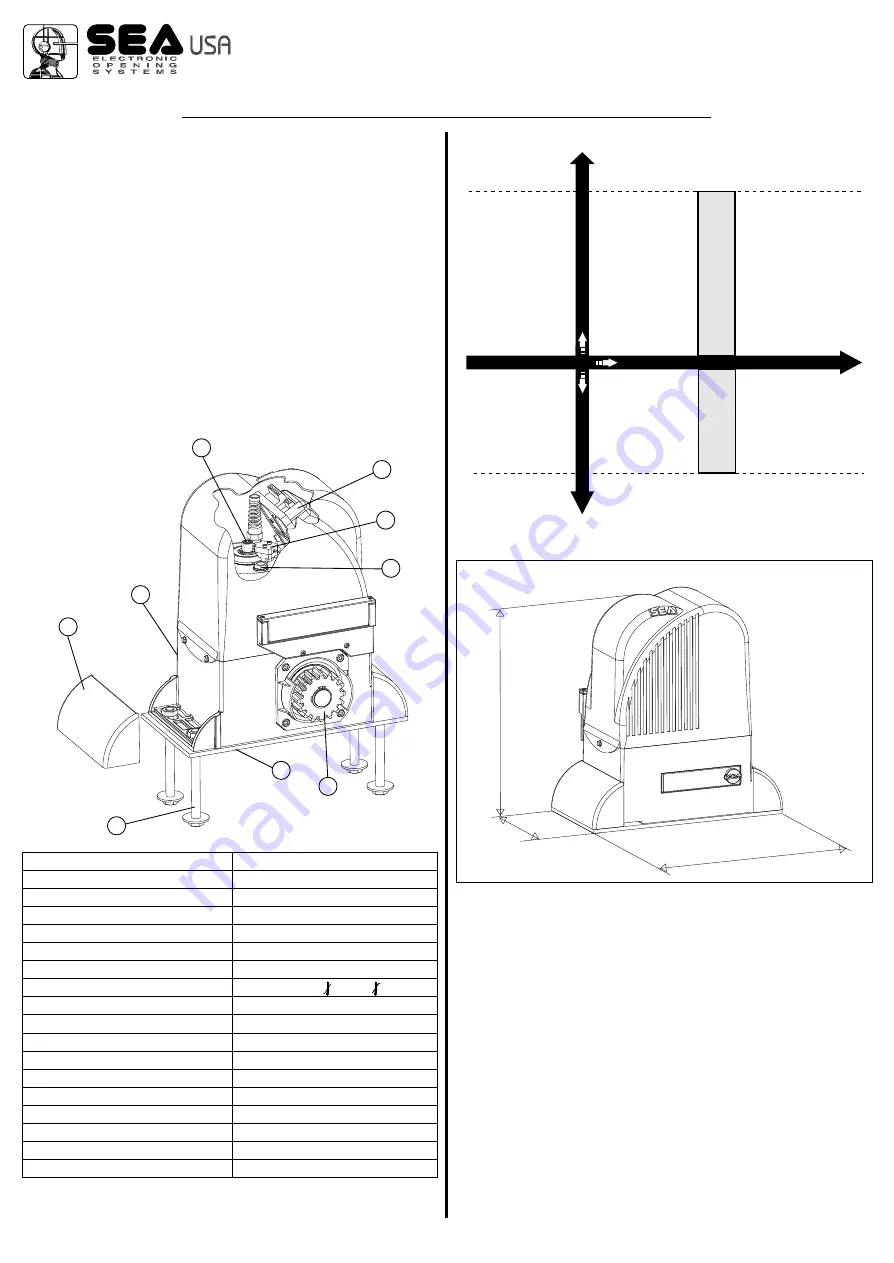

1

Adjustable Foundation plate

2

Anchor bolts

3

Angular cover

4

Pinion

5

Lever release reducer

6

Adjusting screw mechanical clutch

7

Electronic control unit

8

Oil filling up cap

9

Magnetic encoder

MAIN PARTS NOMENCLATURE

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

1. GATE ARRANGEMENT

The first thing to check is that the gate is in good running order as

follows:

a) The gate is rigid and straight and runs smoothly throughout its

travel.

b) that the inferior sliding guide-rail is perfectly straight and

horizontal to avoid a derailment of the gate (fig. 1); furthermore it

must be free of irregularities and foreign bodies which could

obstruct the normal run of the gate (fig. 2 and 3).

c) that the upper guides are not fixed (fig. 4) but furnished with

rollers which allow the sliding of the gate without difficulties (fig. 5

and 6).

d) that the distance between the end of the gate ( in maximum

opening position) and the eventual wall must be at least of 5

inches (fig. 7).

e) The lower support wheels have sealed bearings or grease

MECHANICAL INSTALLATION

4

1

,

8

3

6

12,79

29

6,

DIMENSIONS (inches)