MINI TANK

MARK TANK

230 V (±5%) 50/60 Hz

180 W

220 W

1 A

270 mm

40

50

30 bar

40 bar

-40°C +60°C

130°C

250 daN

640da N

8uF

12,5uF

10 Kg

11 Kg

Ip55

3 mt

4 mt

90° - 110°

FEATURES AND SPECIFICATIONS

The

MINI TANK

and the

MARK TANK

are two high quality hydraulic operators for residential and condominium use with leaf length

up to respectively 3 and 4m.

Available in the following versions:

SC

(with lock only in closing)

SB

(without lock)

AC

(with lock in opening and closing)

The lock is guarantied on leaves with lengths under 1,80m. For leaves which are longer than 1,80m use, for all versions, an electric

lock.

The Mini Tank and the Mark Tank are supplied with by-pass valves for the power regulation in both opening and closing. Electronic

adjustable slow down in opening and closing with control board

GATE 2

. For the European laws and directives actually in force it is

strongly recommended to use the Safety Gate (device for the reading of the gate position), for reverse in case of obstacle.

1

1

3

3

4

4

2

2

8 8

5

Fig. 2

C

IC

L

E

S

/H

O

U

R

OPERATORS

G

R

A

F

IC

O

D

I

U

T

IL

IZ

Z

O

O

P

E

R

A

T

O

R

E

M

IN

I

T

A

N

K

,

M

A

R

K

T

A

N

K

M

IN

I

T

A

N

K

M

A

R

K

T

A

N

K

3 mt

4 mt

40

50

M

IN

I

T

A

N

K

M

A

R

K

T

A

N

K

1

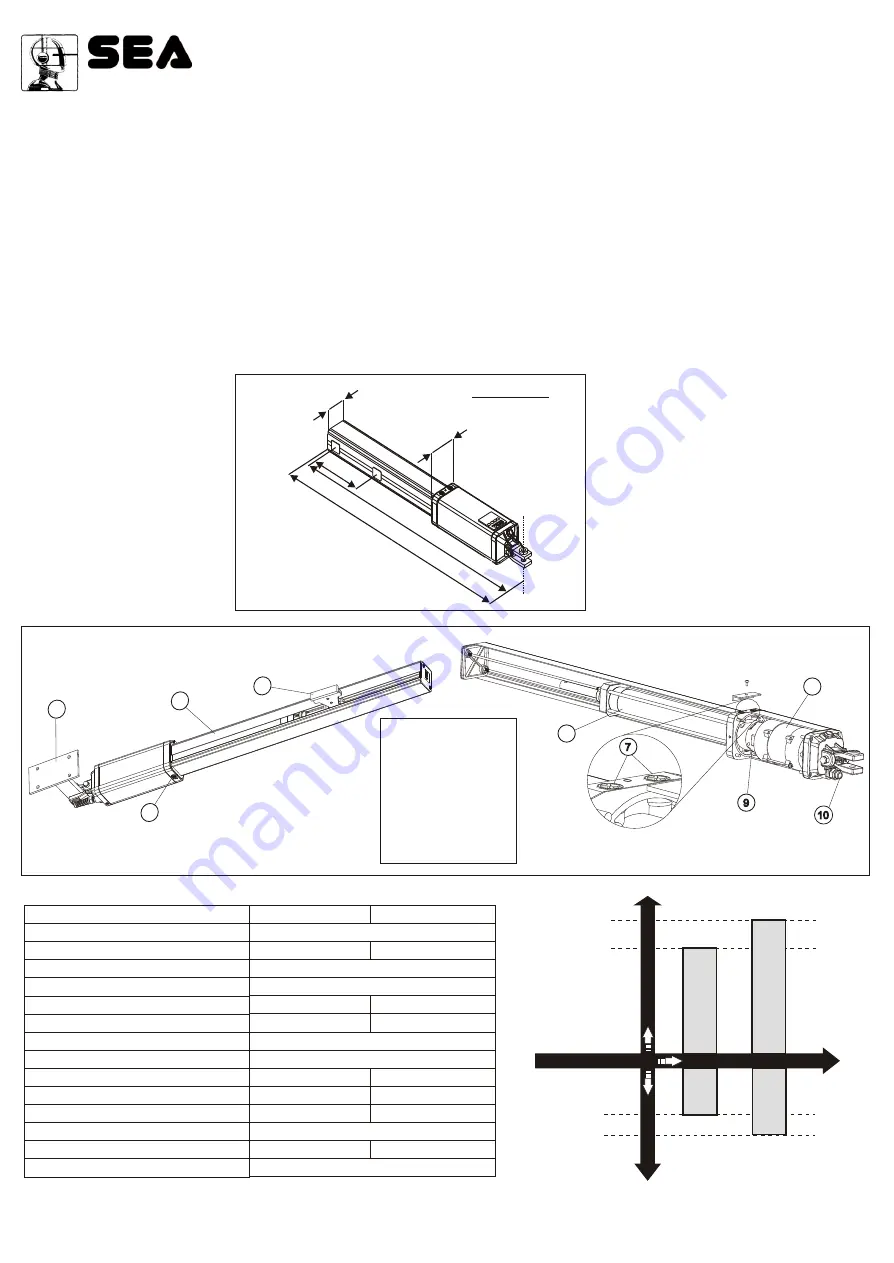

. Shaft cover

2

. release

3

. Front bracket

4

. Rear bracket

5

. Cylinder

6

. Hydraulic piston

7

. By-pass valves

8

. Electric motor

9

. Hydraulic pump

10

. Exit electric cables

TECHNICAL FEATURES

Operating temperatures

Thermal protection

M

P

Power supply

Power

Absorbed current

Stroke

Cycles hour (at a temp. of 20°C)

Max working pressure

ax Thrust

Capacitor

Weight

rotection class

Max leaf lenght

Opening degree of the leaf

MINI TANK

MARK TANK

14

Dimensions (

mm

)

90

990

0

7

270

105

0

Fig. 1

Automazione Porte

e Cancelli

M

a

x

.

le

a

f

le

n

g

th

REV 01 - 07/2006