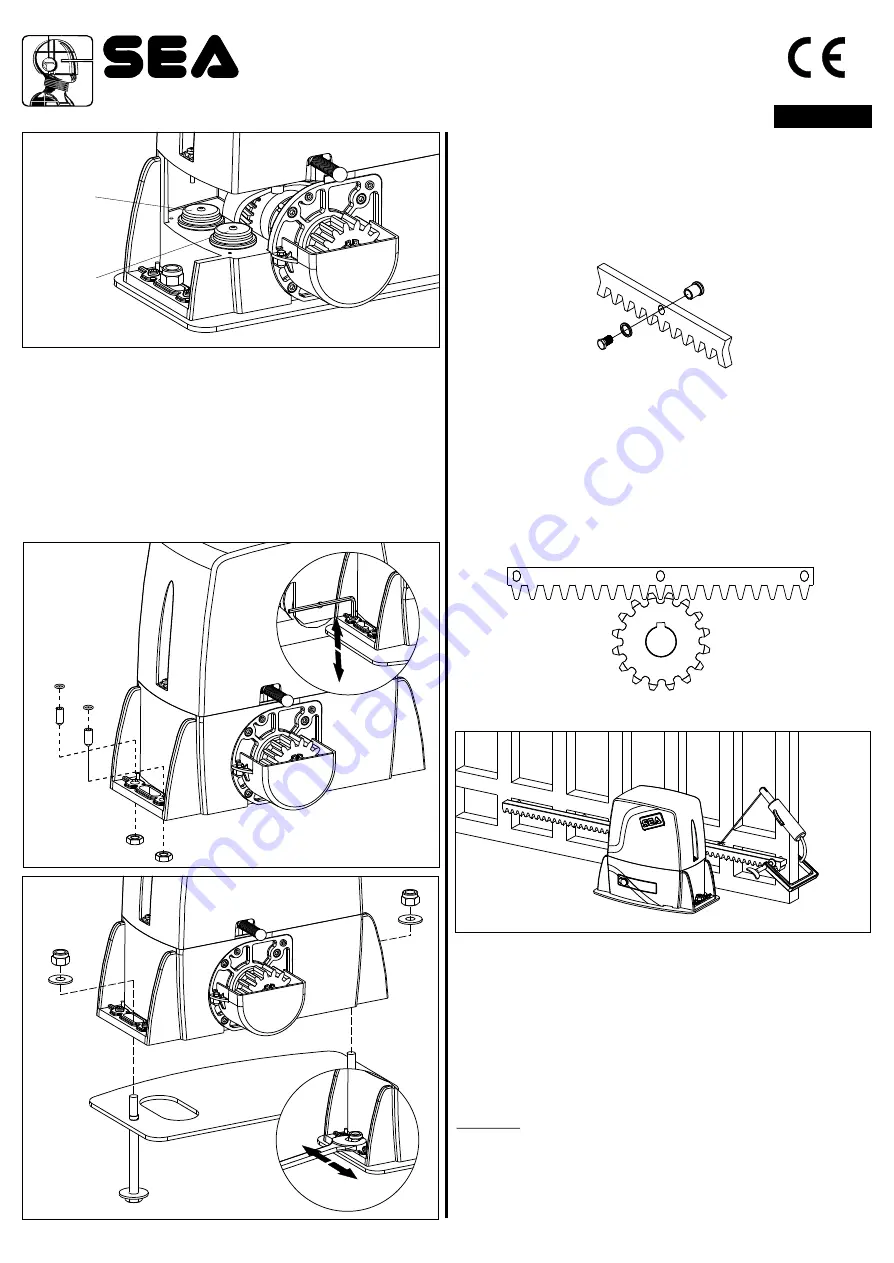

Fig. 3

4. FITTING OF THE MOTOR REDUCER

4.1.

Insert the 4 grains into the special holes, so that it is possible to

adjust the motor reducer height on the plate (Fig. 4).

At the end of installation check if the 4 crub screws are well

gripped on the foundation plate.

4.2.

Fix the motor reducer to the foundation plate with the 2 included

nuts, adjusting the side position (Fig. 5) so to respect the shown quota

in (Fig. 2).

4.3. Remove the closing loading oil cap (red) and substitute it with

that supplied apart provided with the airhole (black).

Hole 1

Hole 2

Fig. 4

Fig. 5

5. GEAR RACK MOUNTING

5.1.

Release the motor and open the leaf completely;

5.2.

Fix on each gear rack element the support pawls with the

appropriate lock screws, make sure to put them in the upper part

of the hole (Fig. 6) ;

5.3.

Lean the gear rack element on the toothed pinion of the

motor in parallel to the ground slideway of the gate, as shown in

Fig. 7 and electrically weld the central pawl B to the gate

structure (Fig. 8).

Manually move the gate until pawl C is placed corresponding to

the pinion and fix it through electric welding. Repeat the same

procedure for pawl A after having placed it corresponding to the

pinion;

5.4.

Make sure that all the gear rack elements are perfectly

aligned and placed correctly (teeth in phase). It’s suggested to

place two aligned elements in front of a third one as shown in

Fig.9;

5.5.

Repeat the above described operation for all the remaining

gear rack elements which have to be installed;

5.6.

To avoid that the door weights down on the pinion (Fig.10)

lift up the whole rack about 1,5 mm.

Warning

: Keep a gap of about 0,5 mm between pinion tooth

and gear rack tooth;

5.7.

Make sure that the gear rack works at the center of the

pinion along all rack elements, if necessary, adjust the length of

the spacers.

Fig. 7

A

B

C

Fig. 6

Fig. 8

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

cod. 67410324

ENGLISH

11

REV 07 - 12/2015