Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

Fig. 25

2x ,5

1

2x1,5

x

3 1,5

1x ,15

2 1,5

x

3x1,5

1

3x ,5

6x1,5

1

8x ,5

1

2

3

4

10

5

6

7

8

9

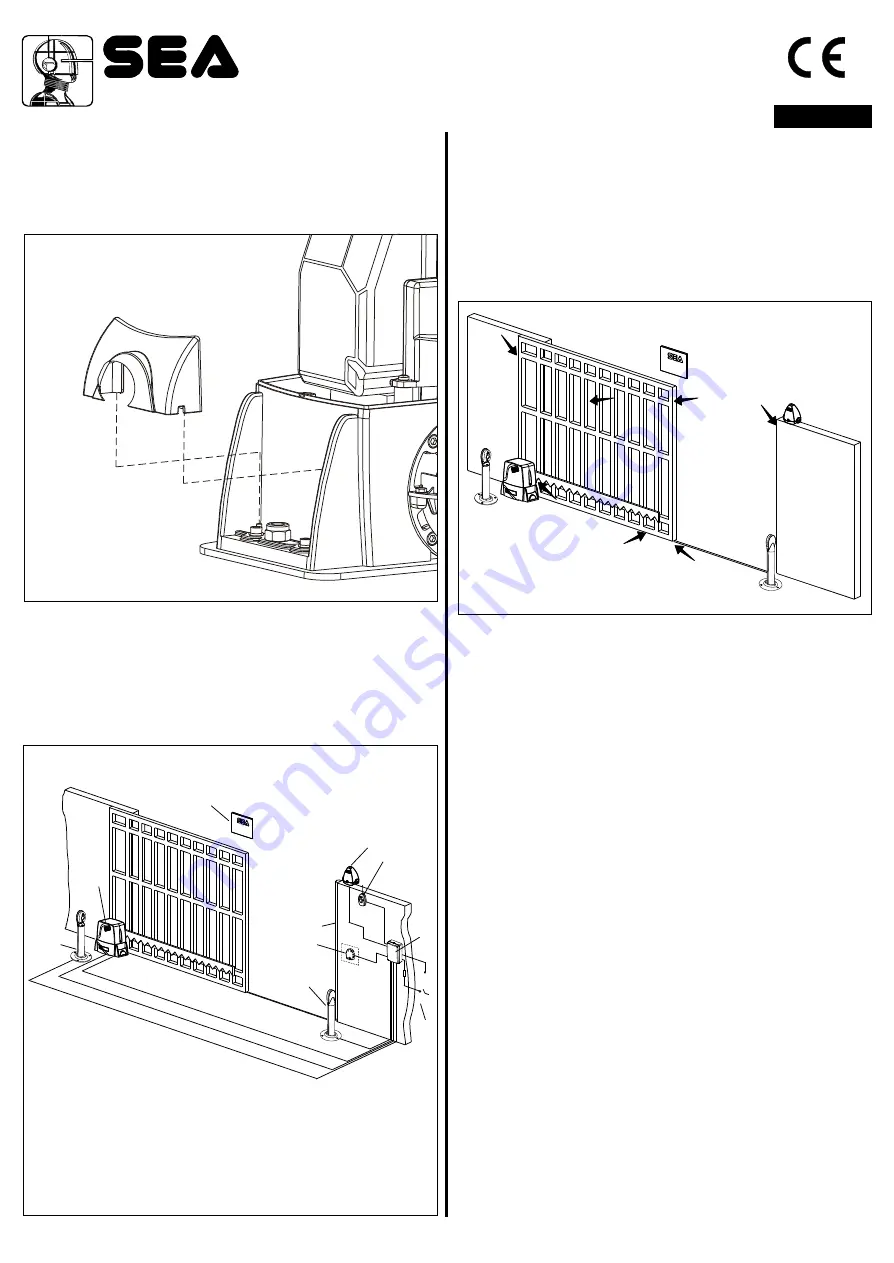

Fig. 24

Fig. 26

10. SCREW COVER MOUNTING

At the end of the mechanical installation and after having

executed all the required adjustments, mount the two screw

covers on the operator as shown in Fig. 24.

11. ELECTRIC CONNECTIONS OF THE

INSTALLATION (Fig. 25)

2

The cable mesures are indicated in mm

1) Saturn - Boxer

2) Photocell Sx

3) Photocell Dx

4) Mechanical safety edge

5) Key push botton

6) Flasher

7) Receiver

8) Warning notice

9) Junction box

10) Differential 16A - 30mA

Ex. 230V version with integrated electronic control unit

12. RISK EXAMINATION

The points pointed by arrows in Fig. 26 are potentially

dangerous. The installer must take a thorough risk examination

to prevent crushing, conveying, cutting, grappling, trapping so

as to guarantee a safe installation for people, things and animals

(

)

Re. Laws in force in the country where the installation has been

made.

13. NOTICE

SEA can not be deemed responsible for any damage or accident

caused by product breaking, being damages or accidents due to

a failure to comply with the instructions herein. The guarantee

will be void and the manufacturer responsibility (according to

Machine Law) will be nullified if SEA original spare parts are not

being used.

This is a quotation from the GENERAL

DIRECTIONS that the installer must read carefully before

installing. Packaging materials such as plastic bags, foam

polystyrene, nails etc must be kept out of children’s reach as

dangers may arise.

The electrical installation shall be carried out by a professional

technician who will release documentation as requested by the

laws in force.

14.

15.

SAFETY PRECAUTIONS:

All electrical work and the choice of the operating logic should

conform to current regulations. A 16 A 0,030 A differential

switch must be incorporated into the source of the operators

main electrical supply and the entire system properly earth

bonded. Always run mains carrying cables in separate ducts to

low voltage control cables to prevent mains interference.

SPARE PARTS:

To obtain spare parts contact:

SEA S.p.A. -Zona Ind.le, 64020 S. ATTO Teramo Italia

ENGLISH

14

cod. 67410324

REV 07 - 12/2015