Operator for roll-up doors

9

English

SPECIFICATIONS FOR INSTALLATION

The motor must be installed in a space provided with prote

cti

on so that special tools only are needed for

assembly. This prote

cti

on will prevent contact with the crumple zone of the door itself. The prote

cti

on would

not be necessary if the installa

ti

on is done at a height exceeding 2.7 meters. In case of Dead Man fun

cti

oning,

the command pos

iti

on must be installed near the gate, in a pos

iti

on to allow the direct and complete

visualiza

ti

on of the same. In case of doors with empty elements, you must verify the absence of

fi

xed structures

near the door, which can create zones of crushing. Photocells or sensors will be installed when required by

applicable laws. The use of photocells or sensors is required when you install more than one centralized

automated door or in case door is automated in an area that is not under direct control.

RULES TO AVOID ACCIDENTS DURING THE MAINTENANCE

Maintenance should be performed only after the motor has been prepared in safety mode. This is achieved by

ac

ti

va

ti

ng the switch pole, making sure it does not turn off during the maintenance opera

ti

on (lock, signalling,

etc.).

NOTE TO THE USER

The maintenance or tes

ti

ng of the gear is prohibited to unauthorized personnel.

DESCRIPTION OF THE PRODUCT

Content (Fig. 1). Tools required (Fig. 2)

CONDITIONS OF USE

The

SONG

SONG

range 240 motors are intended for installa

ti

on of doors winding systems by quali

fi

ed personnel. The

range 240 motors are designed and constructed for the installa

ti

on of roller shutters provided with a

compensa

ti

on system (by springs) according to the weight limits indicated in the table related to the technical

speci

fi

ca

ti

ons. It is prohibited the use of the motor in applica

ti

ons other than those men

ti

oned above.

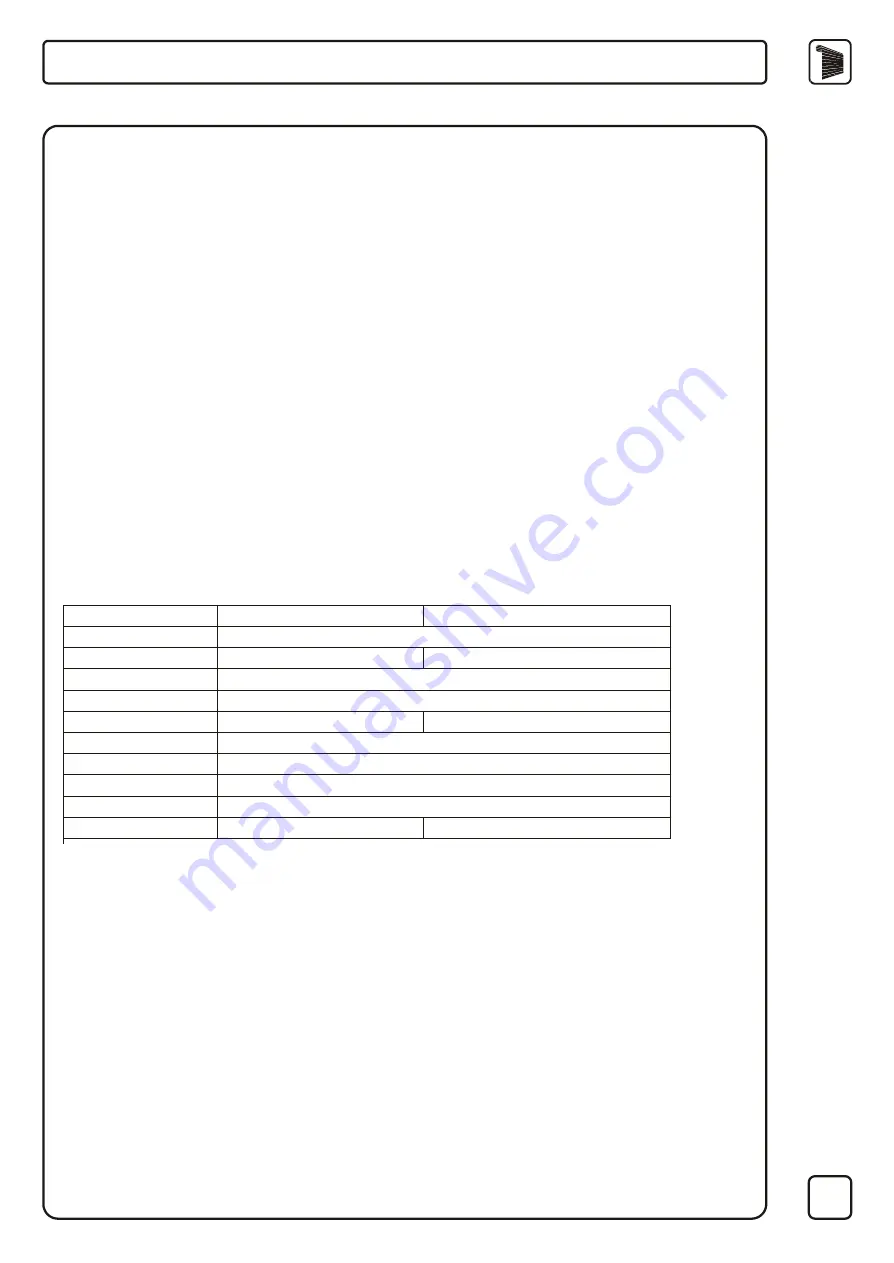

TECHNICAL DATAS

TECHNICAL DATAS

Absorbed power

1200 W

Li

ft

ing

380 Kg.

360 Kg.

Power supply

II 230 V. 50/60 Hz +-7%

Current

5.2 A.

Nominal torque

470 Nm.

450 Nm.

Pulley speed

8 r.p.m.

Working temperature

-20° C +50° C

Maximum door travel

6 m.

Opera

ti

on

ti

me

4. min

Weight of the motor

14 Kg.

15 Kg.

MOUNTING OPER ATIONS

Drill in the shutter's central sha

ft

(Fig. 4) one hole Ø 10 mm. in order the operator doesn't turn, and another Ø 12

mm. for the electric wire. If possible, place the operator in the centre of the shutter's sha

ft

in an easy pos

iti

on for

opening the micro-switches lid to make the wire and the regula

ti

on of the limit switches. In case of electric brake,

make another drill of Ø 10 mm. for the cable of the manual release.

Open the pulley unscrewing the M10x25 screws remove the plas

tic

roller band without folding it and keep it in a

clean place. Separate the gear-motor's body removing the 4 screws with the 8mm(

fi

g.5A). hexagonal wrench.

Couple the two parts of the gear-motor around the door's sha

ft

and joint them, screwing the 4 screws on the gear-

motor's suppo

rt(fi

g.5B). If the tube size is of 101 mm diam., remove de adaptor of 76 mm diam. (see

fi

g. 7).

Tighten the M10x130 screw (Fig. 6 A) entering it into the Ø 10 mm. hole of the shutter's sha

ft

.

Put again the plas

tic

roller band in its place.

Apply again the pulley by coupling the two parts and

tig

hten the screws.

Screw also the M10x50 (Fig. 6 B), bi-motor (

fi

g. 9 B). Pressing on the sha

ft

till

the gear-motor is blocked and

tig

hten

the nut.

SONG 240 101-76

SONG 240 101-76 BRAKE