INSTALLATION WARNINGS

• For gate operators: install only when

A. The operator is appropriate for the gate’s construction and usage Class.

B. All opening spaces on the wall of the horizontal slide gate are guarded or screened from the bottom of the gate to a minimum of 4

feet (1m) above the ground so that it could be possible to keep on the entire surface of the wall a minimum distance of 2-1/4 (57,15mm) inches from the

gate and the wall on which the gate runs.

C. All exposed pinch points are eliminated or guarded

D. Guarding is supplied for exposed rollers.

E. Check if the gate works freely in both directions before installing the gate operator system. Any necessary repair to the gate must be done

before installing the equipment. Swinging gate shall not open into public access areas.

• The operator systems must be installed in a proper place to prevent contacts with adjacent structures in opening and closing. Watch out to install the system so

that users could have full view of the area.

• For operators using non-contact sensors:

A. See instructions on the placement of non-contact sensors for each Type of application.

B. Watch out to reduce the risk of nuisance tripping of the sensor.

C. One or more non-contact sensors shall be located where the risk of entrapment or obstruction exists, such as the perimeter reachable by a moving

gate or barrier.

• For operators utilizing contact sensors:

A. One or more contact sensors must be located where the risk of entrapment or obstruction exists, such as the operators’ edges. They

should be installed both inside and outside the operator’s edge.

B. A hardwired contact sensor must be installed, watching out to arrange its wiring so that the communication between the sensor and the

operator should not be subjected to mechanical damage.

C. A wireless contact sensor such as a radio frequency (RF) signal transmitter must be located where the signal’s transmission cannot be

obstructed by structures or natural landscaping.

• Controls should be far enough from the gate or barrier so that the user is prevented from coming in contact with them while operating the controls. Controls are

intended to be used to reset an operator after 2 sequential activations of the entrapment protection device and must be located in the line-of-sight of the outdoor.

Install a security feature If controls are easily accessible, to prevent unauthorized use.

AFTER INSTALLATION

• Check that: the open and close force are properly adjusted; the piston does not bottom out in either direction, the breather screws have been removed, the

positive stops used are sufficient for stopping the gate properly, all the pinch points and potential entrapment areas are reduced.

• Check and test all reversing devices.

• The installer should instruct user on the operator system’s proper operation. They should together review the basic functions of the reversing devices and how to

periodically test them. Reversing devices include one or more of the followings: reversing loops, photocells, reversing edges, etc. The installer has to instruct

user on how to remove the operator system from service, on shutting power off on the service panel and how to use the operator system manually.

GENERAL ENTRAPMENT PROVISIONS

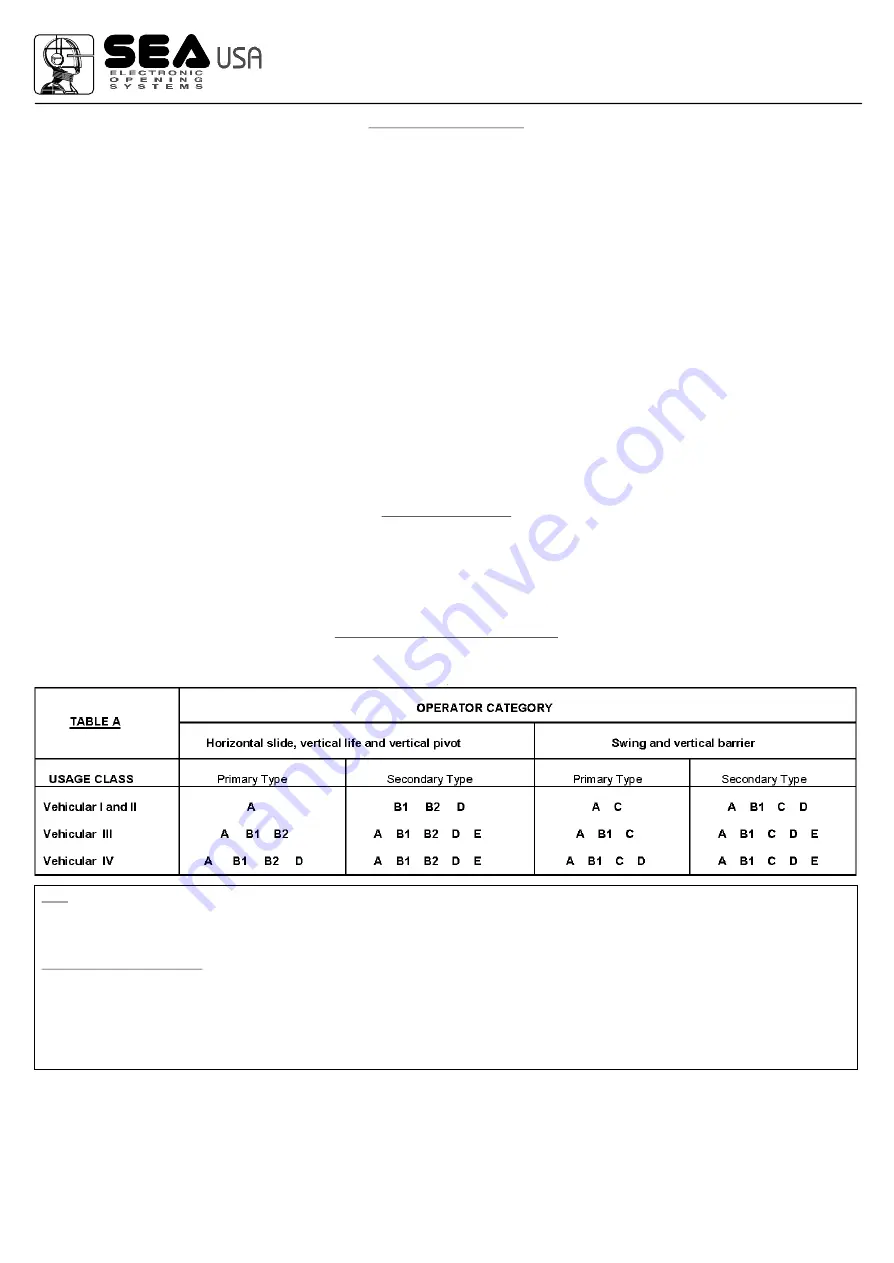

A vehicular operator must be installed with one independent primary and one independent secondary means at least to protect against entrapment

(see Table A):

Note

: The same type of device shall not be utilized for both the primary and secondary entrapment protection means. The use of a single device to cover both

the opening and closing directions is in accordance with the requirements; however, a single device is not required to cover both directions. A combination of

one Type B1 for one direction and one Type B2 for the other direction is the equivalent of one device, for the purpose of complying with the requirements of

either the primary or secondary entrapment protection means.

Entrapment protection types

Type A:

Inherent entrapment sensing system.

Type B1: Provision for connection of a non-contact sensor (photoelectric or equivalent).

Type B2: Provision for connection of a contact sensor (edge device or equivalent).

Type C:

Inherent adjustable clutch or pressure relief device.

Type D:

Provision for connection of an actuating device requiring continuous pressure to maintain opening or closing motion of the gate.

Type E:

An inherent audio alarm.

CLASS OF OPERATORS

RESIDENTIAL VEHICULAR GATE OPERATOR - CLASS I - A vehicular operator (or system) intended for use in a home of one-to four, single-family dwelling, or

a garage or parking area associated therewith.

COMMERCIAL/GENERAL ACCESS VEHICULAR OPERATOR - CLASS II - A vehicular operator (or system) intended for use in a commercial location or

building such as multi-family housing unit (five or more single family units), hotel, garage, retail store, or other building servicing the public.

INDUSTRIAL/LIMITED ACCESS VEHICULAR OPERATOR - CLASS III - A vehicular operator (or system) intended for use in an industrial location or building

such as a factory or loading dock area or other locations not intended to service the public, in which unauthorized access is prevented via supervision by security

personnel.

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151

Fax: ++1-305.594.7325

Toll Free: 800.689.4716

®

International registered trademark n. 2.777.971

Storm 24V

Rev. 00 - 11.2010

Code 67411125

3

Summary of Contents for STORM 24V

Page 15: ......