7

20.7”

13.6”

12.8”

V (±5%) 50/60 Hz

120

350W

3,2 A

15 Nm

60 µF

11 In/s

30 %

integrated

1000 Lb

16,4 ft

electromechanical

from -4°F to 131°F

73 lb

IP 55

I II III IV

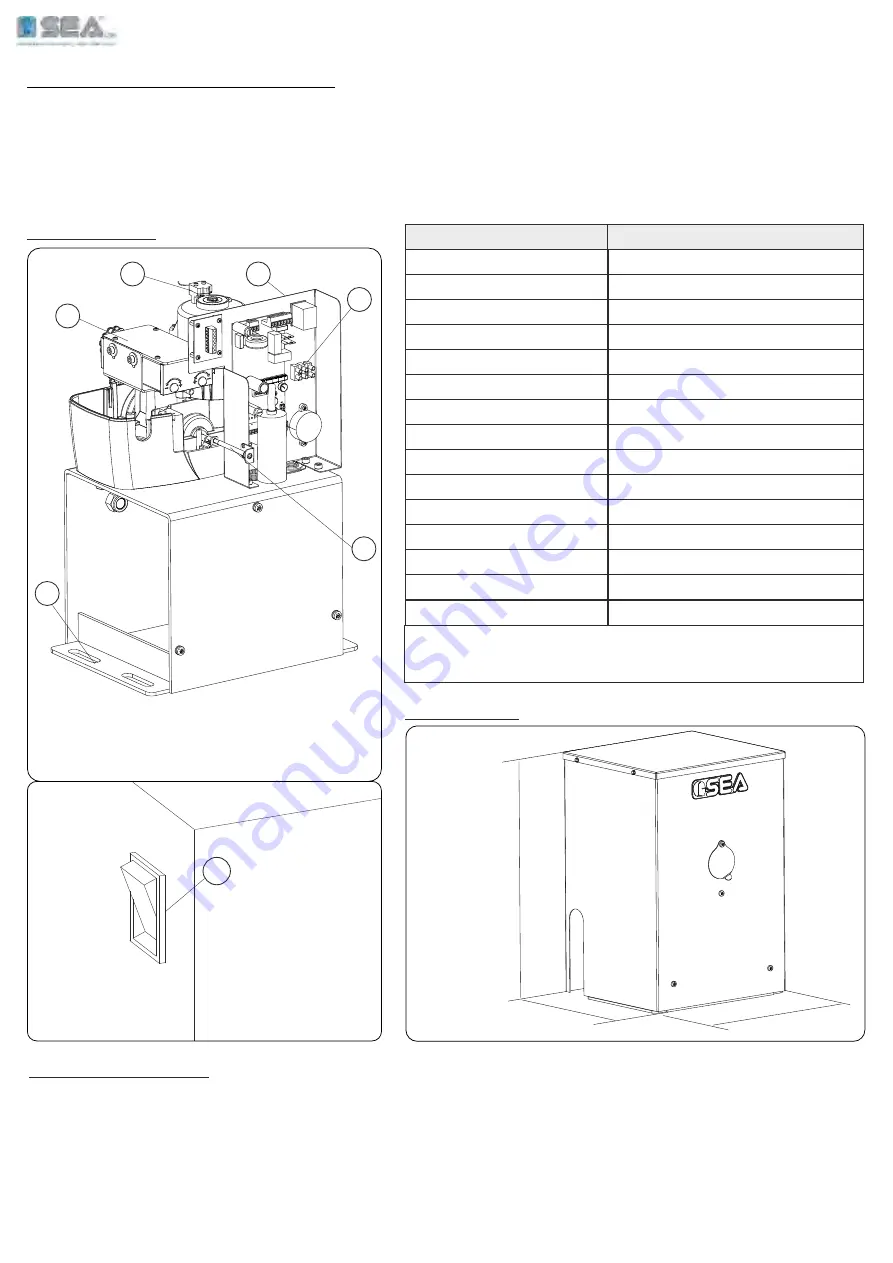

1. FEATURES AND SPECIFICATIONS

TAURUS BOX is an electro-mechanical reduction operator. The TAURUS BOX can be supplied with either

mechanical clutch or electronic sensing device as methods of limiting the motor torque. The gates open &

close stop limits are accurately stored by mechanically triggering the on-board micro-switch. Manual release

is quickly achieved by operating a key manual release system.The control unit allows to choose between

automatic or semi-automatic control logic and will provide all normal safety logic functions

TECHNICAL FEATURES

Power supply

Power

Absorbed current

Thrust force

Capacitor

Leaf speed (pinion Z17)

Use rate

Thermal protection

Max gate weight

Max gate opening

Type of limit switch

Operating temperatures

Operator weight

Protection class

Classification

TAURUS BOX 1000 FAST

1

2

3

4

5

6

NOTE: The frequency of use is valid only for the first

hour at 68° F room temperature

2. GENERAL SWITCH

Into TAURUS BOX you can find a general switch (Fig. 13) which allows to turn on or off the electric power

supply. This switch must be set on «

I

» to start the operator

CAUTION:

Operator

must

be

started

only

after

having

correctly

installed

and

adjusted

all components

WARNING!

It is mandatory to switch off the power supply by putting switch to «

O

» when you need to work on

the operator (eg. repairs, power loss, components installation).

COMPONENTS

DIMENSIONS

6

Fig. 12

Fig. 13

Fig. 14

1

Release

2

Magnetic encoder

3

Limit switch

4

Foundation plate

5

Control unit

6

General switch