Fig. 10

Sistemi elettronici

di Aperture Porte e Cancelli

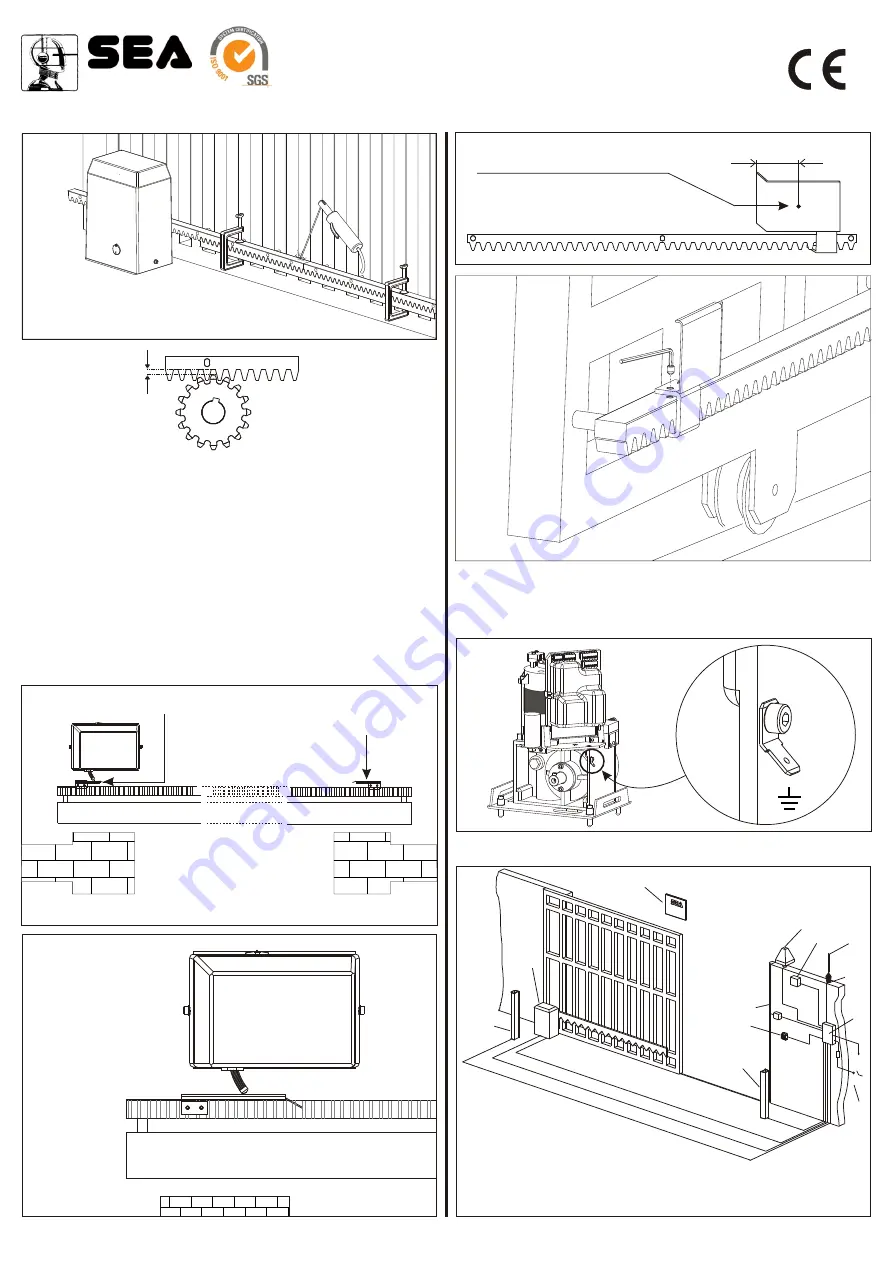

6. LIMIT SWITCH ADJUSTMENT

6.1.

To set up and adjust the limit switches in opening, follow the instructions

written here (Fig. 12):

- Bring the gate in complete opening,

- Place the limit switch plate on the gear rack to have the limit switch (spring in

case of mechanical limit switch (Fig. 13)) in correspondence with the X point

which is 50 mm from the folded side of the plate (Fig. 14) and fix it with the

supplied screws (Fig. 15).

6.2.

To set up and adjust the limit switches in closing, follow the instructions

written here (Fig. 12):

- Bring the gate in complete closing,

- Place the limit switch plate on the gear rack to have the limit switch in

correspondence with the X point which is 50 mm from the folded side of the plate

(Fig. 14) and fix it with the supplied screws (Fig. 15).

Fig. 12

1,5 mm

Fig. 11

Closing limit switch

Opening limit switch

Fig. 13

Fig. 15

50 mm

X

Fig. 14

Place where the spring (mechanical

limit switch)

Through the braking trimmer adjustment placed on the electronic control unit it is

possible to stop the gate in the point desidered.

7. GROUNDING (Fig. 16)

8.

(Fig. 17)

CABLE LAYOUT

2x

5

1,

2x ,5

1

3x1,5

1x1,5

1 5

2x ,

1

3x ,5

1,5

2x

x1

3

,5

6 1,5

x

x

8 1,5

1xRG58

1

2

3

4

11

5

6

7

8

9

10

Fig. 17

REV 01 - 03/2005

1) TORG operator

2) Left photocell

3) Right photocell

4) Pneumatic safety edge

5) Key switch

6) Flashing warning lamp

7) Radio receiver

8) Antenna

9) Warning notice

10)Electronic control unit

11) 16A- 30mA differential switch

Fig. 16