Sistemi elettronici

di Aperture Porte e Cancelli

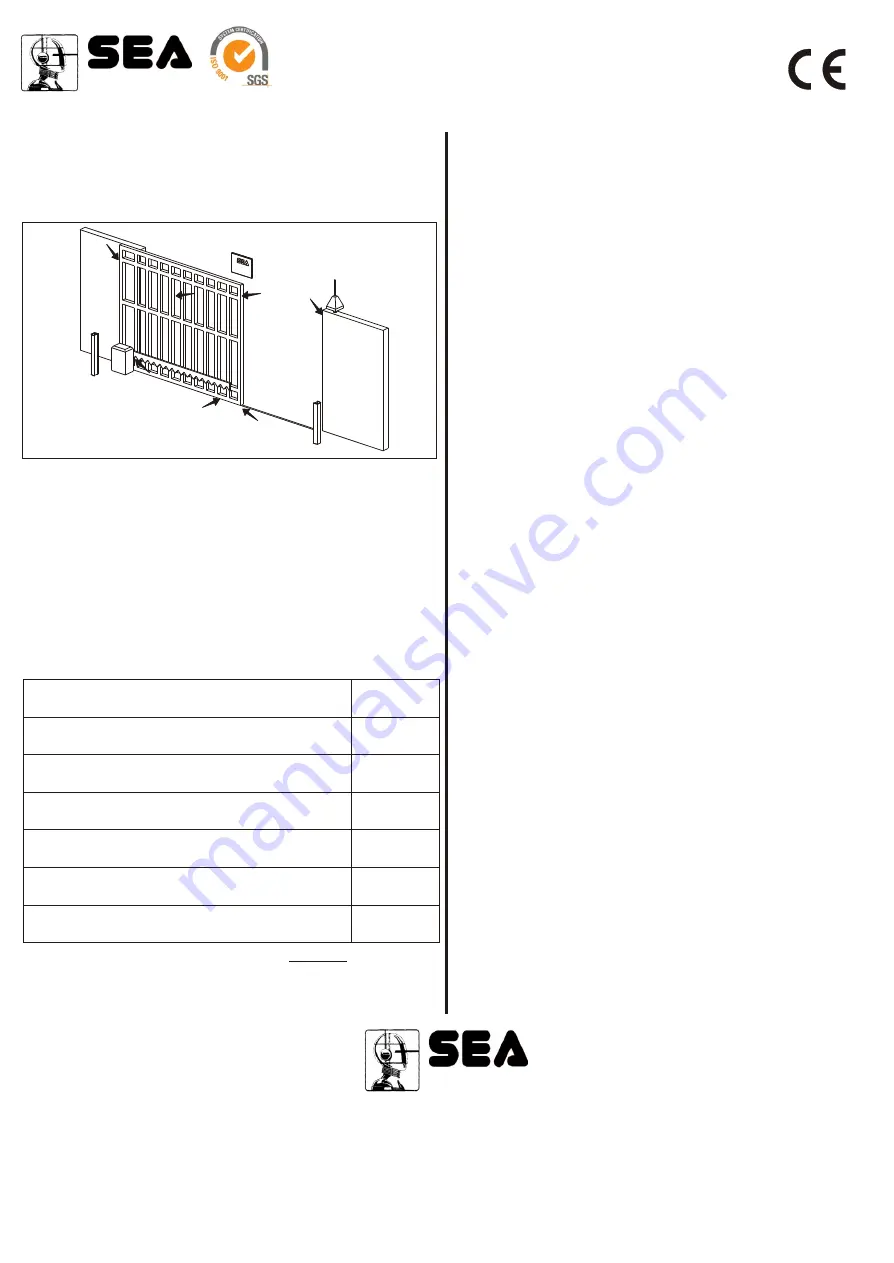

9. RISK EXAMINATION

The points pointed by arrows in Fig. 18 are potentially dangerous. The installer

must take a thorough risk examination to prevent crushing, conveying, cutting,

grappling, trapping so as to guarantee a safe installation for people, things and

animals (

)

Re. Laws in force in the country where the installation has been made.

NOTICE

SEA s.r.l can not be deemed responsible for any damage or accident caused by

product breaking, being damages or accidents due to a failure to comply with the

instructions herein. The guarantee will be void and the manufacturer

responsibility (according to Machine Law) will be nullified if SEA Srl original spare

parts are not being used.

This is a quotation

from the GENERAL DIRECTIONS that the installer must read carefully before

installing. Packaging materials such as plastic bags, foam polystyrene, nails etc

must be kept out of children’s reach as dangers may arise.

The electrical installation shall be carried out by a professional technician who

will release documentation as requested by the laws in force.

Fig. 18

PERIODICAL MAINTENANCE

Check the release function

Verify the functioning of the electronic clutch

Check the distance between the pinion and the rack

(1.5 mm)

Check the wear condition of the pinion and of the rack

Check the fixing screws

Check the integrity of the connection cables

Check the function and the limit switch condition in opening

and closing and the related plates

Annual

Annual

Annual

Annual

Annual

Annual

Annual

All the above described operations must be made exclusively by an authorized

installer.

Sistemi elettronici

di Aperture Porte e Cancelli

SEA S.r.l.

Zona industriale 64020 S.ATTO Teramo - (ITALY)

Tel. 0861 588341 r.a. Fax 0861 588344

www.seateam.com

seacom@seateam.com

DECLARATION OF CONFORMITY

SEA declares under its responsibility that the product

Torg

meet the essential requisites provided for by the following European Directive

and following changes:

89/392/CEE (Machine Directive)

89/336/CEE (Electromagnetic Compatibility Directive)

73/23/CEE (Low Tension Directive)

SAFETY PRECAUTIONS:

All electrical work should conform to current regulations. A 16 A 0,030 A

differential switch must be incorporated into the source of the operators main

electrical supply and the entire system properly earth bonded. Always run mains

carrying cables in separate ducts to low voltage control cables to prevent mains

interference.

INTENDED USE:

The Torg operator has been designed to be solely used for the automation of

sliding gates.

SPARE PARTS:

To obtain spare parts contact:

SEA s.r.l. -Zona Ind.le, 64020 S. ATTO Teramo Italia

SAFETY AND ENVIRONMENTAL COMPATIBILITY:

Don’t waste product packing materials and/or circuits.

When being transported this product must be properly packaged and handled

with care.

MAINTENANCE AND OUT OF SERVICE:

The decommission and maintenance of this unit must only be carried out by

specialised and authorised personnel.

NOTE: THE MANUFACTURER CAN NOT BE DEEMED RESPONSIBLE FOR

ANY DAMAGE OR INJURY CAUSED BY IMPROPER USE OF THIS

PRODUCT.

SEA

reserves the right to do changes or variations that may be necessary to its

products with no obligation to notice.

IMPORTANT:

SEA advises the installation of Encoder system for higher anti-crushing

security where not foreseen.

REV 01 - 03/2005