32

Viper 200 LTO Product Manual

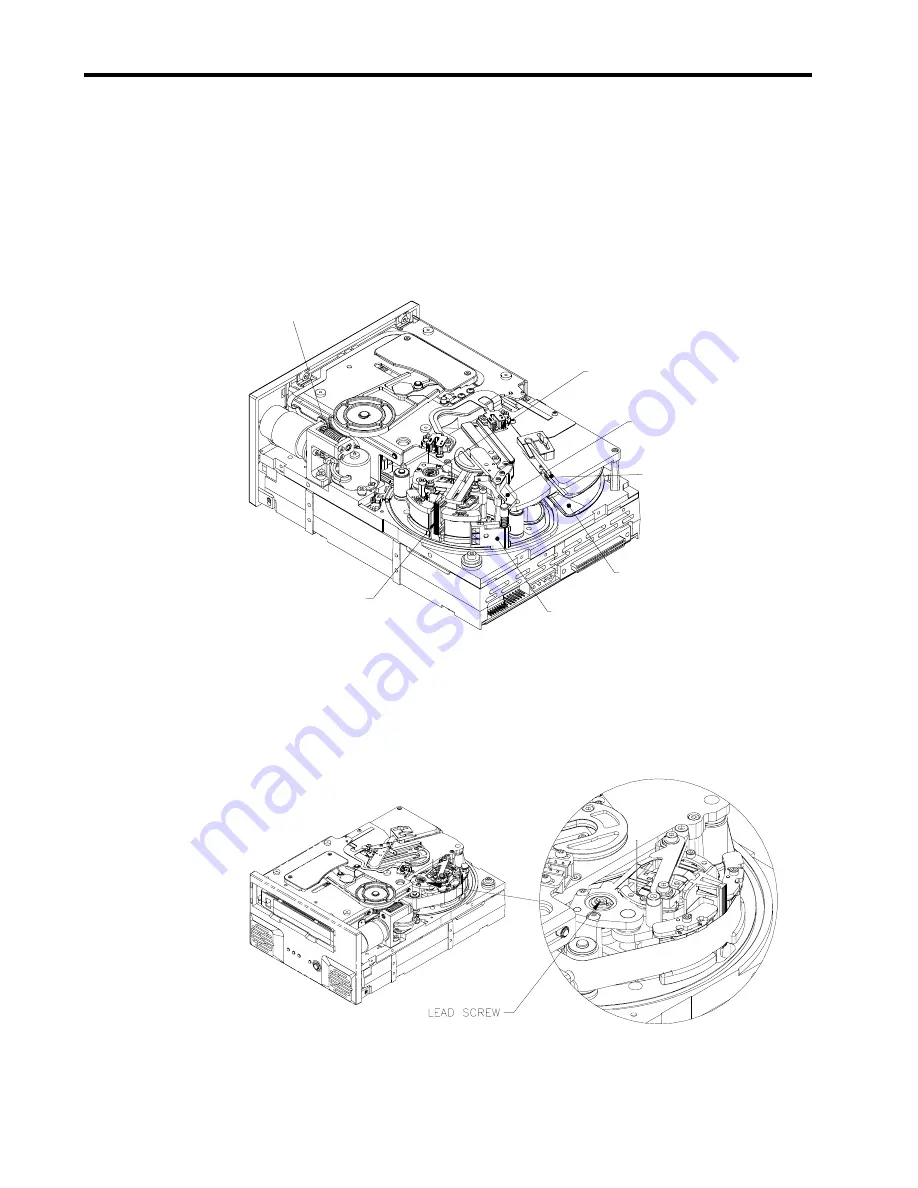

Case 2. Cartridge is loaded and seated and tape is threaded

Follow these steps if the cartridge is loaded and seated, and the tape is entirely or

partially threaded into the drive. You will need a small, flat-blade screw driver and an

M2 hex-head screw driver. Figure 13 shows key components of the drive mechanism

that are referred to in the text below.

Note. Do not touch any part of the drive mechanism except for the components

specified in the instructions.

Worm gear

Head assembly

Tape grabber

Lead screw

Load arm

Take-up reel

and hub

Slot in

drive chassis

Figure 13. Diagram of Viper 200 showing key components used in manual cartridge

tape removal (no tape cartridge in drive).

1.

Make sure the head assembly is in the lowered position by turning the lead

screw (shown in Figure 14) clockwise with the flat blade screwdriver. This is

necessary to allow the load arm to clear the head assembly when it is moved

back toward the cartridge.

Figure 14. Diagram of Viper 200 showing lead screw (tape threaded on take-up reel)