“Graphics and specifications may change without notice”.

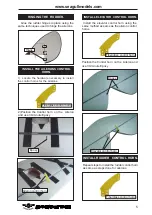

MS:169

ASSEMBLY MANUAL

Specifications:

Wing span ------------------------------66.9in (170cm).

Wing area -----------------764.2sq.in (49.3sq dm).

Weight ------------------------10.6lbs (4.8kg).

Length ------------------------------58.7in (149.0cm).

Engine ------------------ 0.75-0.91cu.in ----2-stroke.

Engine ------------------ 0.91-1.10cu.in ----4-stroke.

Radio -------------------4 channels with 6 servos.

Electric conversion: optional

Flying skill level Advanced/Intermediate.

?