WWW.SEAGULLMODELS.COM

19

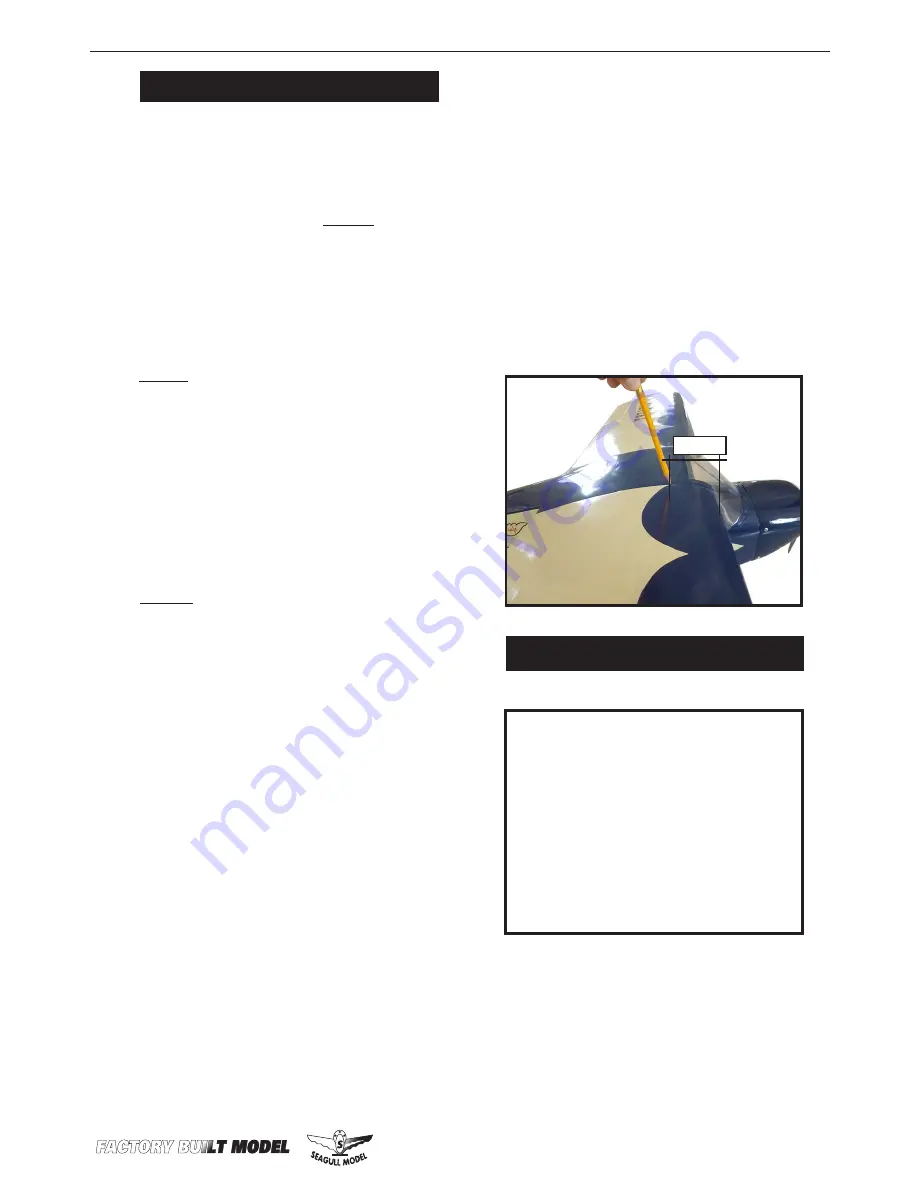

BALANCING.

1) It is critical that your airplane be

balanced correctly. Improper balance will

cause your plane to lose control and

crash. THE CENTER OF GRAV-

ITY IS LOCATED

75MM

BACK

FROM THE LEADING EDGE OF

THE WING AT THE WING ROOT.

3) Turn the airplane upside down. Place

your fingers on the masking tape and

carefully lift the plane .

Accurately mark the balance point on

the botttom of the wing on both sides of

the fuselage. The balance point is located

75mm

back from the leading edge of the

wing at the wing root. This is the bal-

ance point at which your model should

balance for your first flights. Later, you

may wish to experiment by shifting the

balance up to 10mm forward or back to

change the flying characteristics. Mov-

ing the balance forward may improve

the smoothness and arrow- like tracking,

but it may then require more speed for

take off and make it more difficult to slow

down for landing. Moving the balance aft

makes the model more agile with a light-

er and snappier ”feel”. In any case,please

start at the location we recommend .

With the wing attached to the fuselage,

all parts of the model installed ( ready to

fly), and empty fuel tanks, hold the mod-

el at the marked balance point with the

stabilizer level.

2) Mount the wing to the fuselage. Using

a couple of pieces of masking tape, place

them on the bottom side of the wing

75mm

back from the leading edge of the

wing at the wing root.

Lift the model. If the tail drops when

you lift, the model is “tail heavy” and you

must add weight* to the nose. If the nose

drops, it is “nose heavy” and you must

add weight* to the tail to balance.

*If possible, first attempt to balance the

model by changing the position of the re-

ceiver battery and receiver. If you are un-

able to obtain good balance by doing so,

then it will be necessary to add weight to

the nose or tail to achieve the

proper balance point.

75 mm

CONTROL THROWS.

Ailerons:

Up : 15 mm

Down : 15 mm

Elevator:

Up : 20 mm

Down : 20 mm

Rudder:

Right : 25 mm

Left : 25 mm