Bowers Flybaby

10

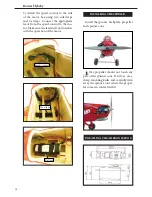

2) Use a pin drill and 4mm drill bit to

drill a small indentation in the mount for

the engine mounting screw.

3) Use a drill to drill the four holes in the

engine mount rails.

4mm

Machine screw M4x30mm

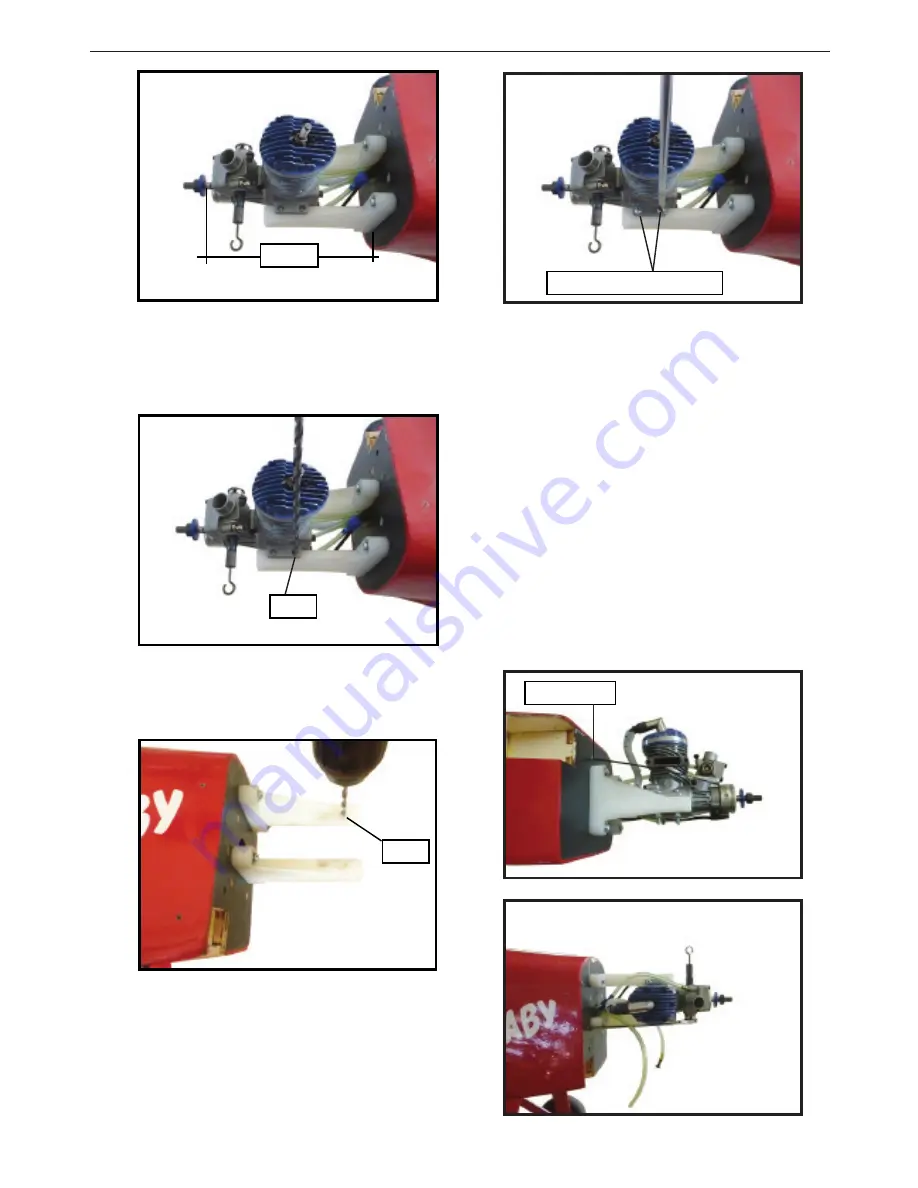

4) On the fire wall has the location for the

throttle pushrod tube (pre-drill).

5) Slide the pushrod tube in the firewall

and guide it through the fuel tank mount.

Use medium C/A to glue the tube to the

firewall and the fuel tank mount.

6) Connect the Z-bend in the 450mm

throttle pushrod to the outer hole of the

carburetor arm.

7) Slide the throttle pushrod wire into

the tube. Position the engine between the

mounts. Use four M4x30mm machine

screws to secure the engine to the mount

as shown.

Pushrod wire.

4mm

145mm

Summary of Contents for SEA238

Page 18: ...Bowers Flybaby 18 M4x20mm Collar M4x20mm Thread locker glue Collar Collar ...

Page 24: ...Bowers Flybaby 24 INSTALL BRACING WIRE AND METAL BRACKET AT THE TAIL TOP VIEW ...

Page 26: ...Bowers Flybaby 26 INSTALL FIBERGLASS HORN Epoxy Springs M3x10mm ...

Page 29: ...Instruction Manual 29 BOTTOM VIEW Do the same way with another half wing ...

Page 32: ...Bowers Flybaby 32 ...