Section 3. Periodic Maintenance

18

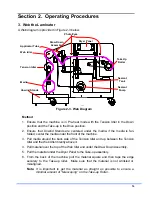

Level 2 Cleaning

(Detailed Cleaning)

Detailed cleaning is recommended once a month. Under extremely heavy use

this may be necessary more often.

1. Perform all the steps listed in level 1 cleaning.

2. Remove the Sealant Tank by closing the valves in front of the quick-disconnects

and disconnecting the tank from the pump supply hose.

3. Pour the sealant from the tank into a container and reinstall the tank into the

machine.

4. Fill the Sealant Tank with clean water.

5. Turn the machine ON at the Main Power Switch.

6. Switch machine into RESET mode.

7. Open the Distribution Valves in the Applicator Tube.

8. Turn ON Sealant Pump and let the water flush the system for 5 minutes.

9. Turn Sealant Pump OFF.

10. Remove and clean the screen in the Sealant Pump Filter. Simply running the

screen under a faucet will do this.

11. Reinstall Filter Screen ensuring that the bowl is screwed back on securely.

12. Remove the Sealant Tank and dispose of the water.

13. Reinstall tank and refill with Sealant.

14. Ensure all valves are in their proper position for normal operation.

15. Turn the machine OFF at the Main Power Switch.

16. Wipe up any water from Draw Down Assembly and dry off all parts.