20

D E C A L I N G ( P R E S S U R E - S E N S I T I V E )

This process involves applying a cold pressure-sensitive

over-laminate to the top and a cold pressure-sensitive

mounting adhesive to the bottom of a graphic. If

desired, set the top roller’s temperature to 120

°

F

(49

°

C). Using heat-assist may improve the adhesive

bonding of the laminate. This process can be used to

create self-adhesive images for mounting down onto

various substrates. After performing this process, follow

the Mounting Instructions in the manual to apply the

decal to a substrate. It is important to follow the

webbing instructions for films specific for your location.

MEDIA: I

NK

J

ET

, E

LECTROSTATIC

,

AND

P

HOTOGRAPHIC

FILMS:

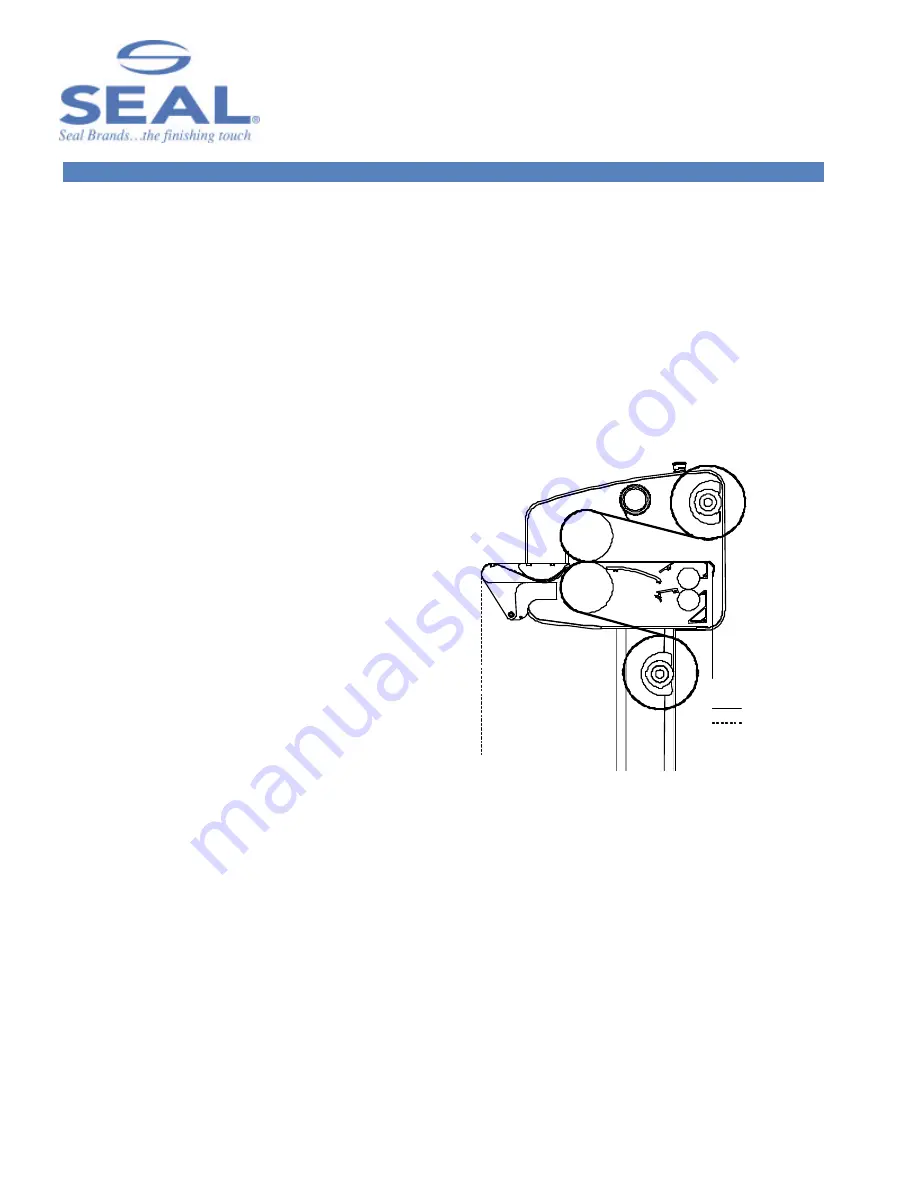

-- -- -- Top Unwind: Pressure-sensitive over-laminate

____ Bottom Unwind: Pressure-sensitive mounting

adhesive

LAMINATOR SETTINGS

C

ONTROL

P

ANEL

Top Roller Temp:

OFF or Heat-assist

Bottom Roller Temp:

OFF

Motor Speed Setting:

3-5 FPM (1-1.5 MPM)

WEBBING SETTINGS

Web Tension Top:

Light

Web Tension Bottom:

Light

Nip Setting:

‘0’

NOTE: When using Mounting Adhesive on the

back of images it is best to run over the back table.

Running the film through the pull rollers may cause

the backing to separate from the release liner.

NOTE! Web the top laminate following the basic

procedures for webbing films with a release liner.

Film Path

Media Path

Release Liner

Figure 13. Webbing for Decaling (Pressure-

sensitive films)