61

End of operation

Removing and cleaning the squeegee

Empty and clean the recovery tank and fresh water tank

Emptying the recovery tank and fresh water tank

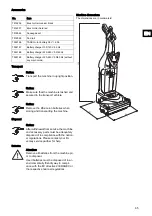

• Press the switch cleaning solution.

The cleaning solution supply is

stopped.

• Allow the suction unit to run further so that the remaining

water in the hose will be sucked out.

• Switch off the suction unit.

The suction motor is switched off.

• Switch off the machine (main switch).

• Bring the machine to a parking and

transport position.

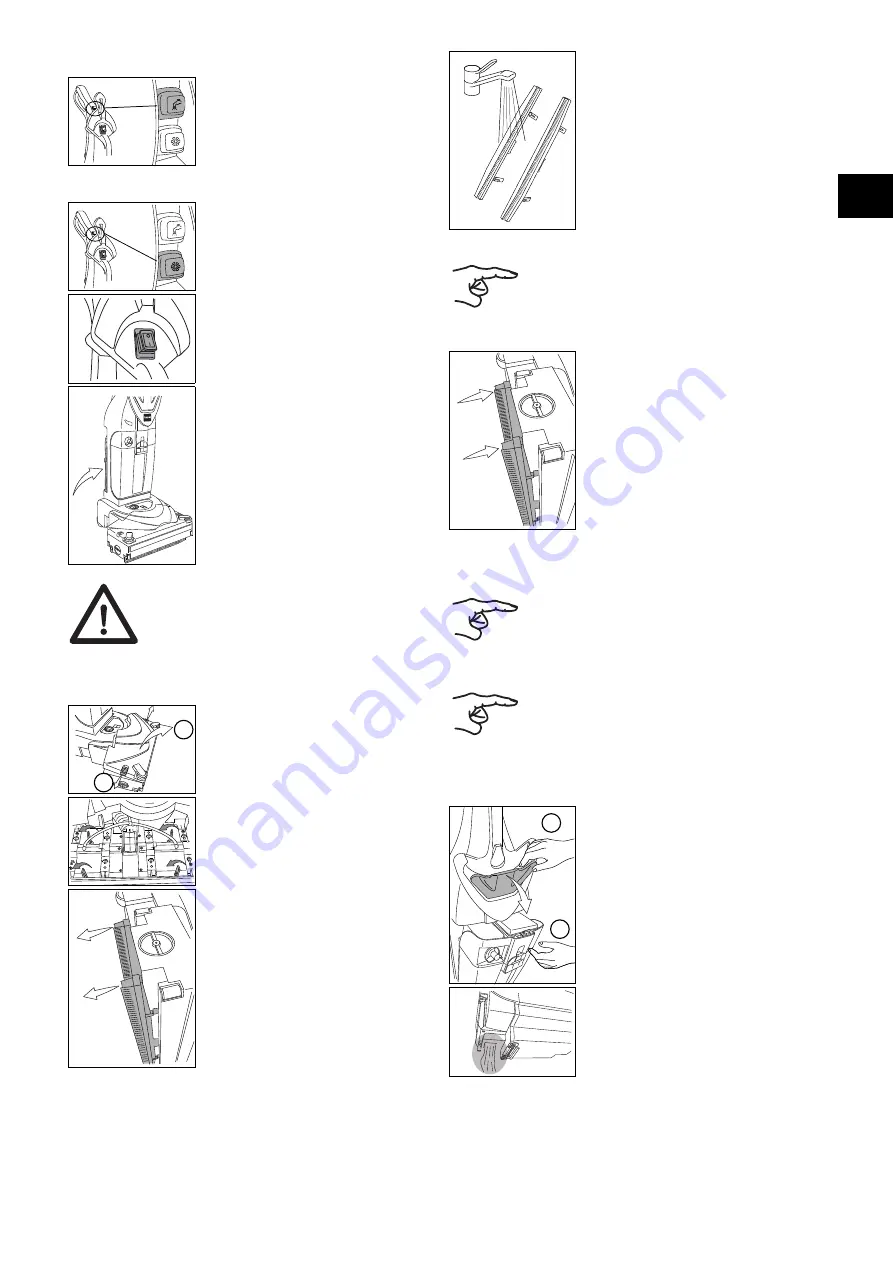

Attention:

The machine must now be emptied and

cleaned. Switch off the machine (main

switch) and remove the plug from the

mains socket.

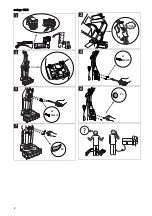

• Open the cover of the brush housing

by loosening the side latches.

• Turn the four yellow clips to the left to

loosen the squeegees.

• Turn the machine onto the side to re

-

move the squeegees.

1

2

• Wash out the squeegees under run

-

ning water.

Notice:

Check the condition of the suction lips be

-

fore the installation.

Bristles that are too short or damaged suc

-

tion lips will impair the cleaning result!

• Reinstall the squeegees into the

squeegee body.

In doing this, note that the front and

rear squeegees are different. The po

-

sition is shown on the upper side of

the squeegees. (FRONT + REAR)

Notice:

Drain water or cleaning solution must be

disposed of in compliance with the nation

-

al regulations.

Notice:

When draining the recovery tank, the reg

-

ulations of the detergent supplier regard

-

ing personal protective equipment must be

observed.

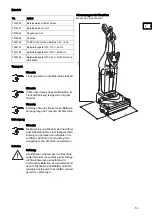

• Remove the tank by pulling on the

tank unlocking device (1).

• Hold the tank (2) with the other hand

so that it does not fall out of the hold

-

er when unlocked.

• Pull the solution tank out of the hold

-

er.

• Empty the dirty water from the tank

through the opening provided at the

rear.

2

1

EN