63

Cleaning the brush housing

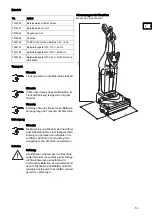

Installing/Replacing the brush roller

Cleaning the transport wheels

Cleaning the machine

Storing / parking the machine (not in operation)

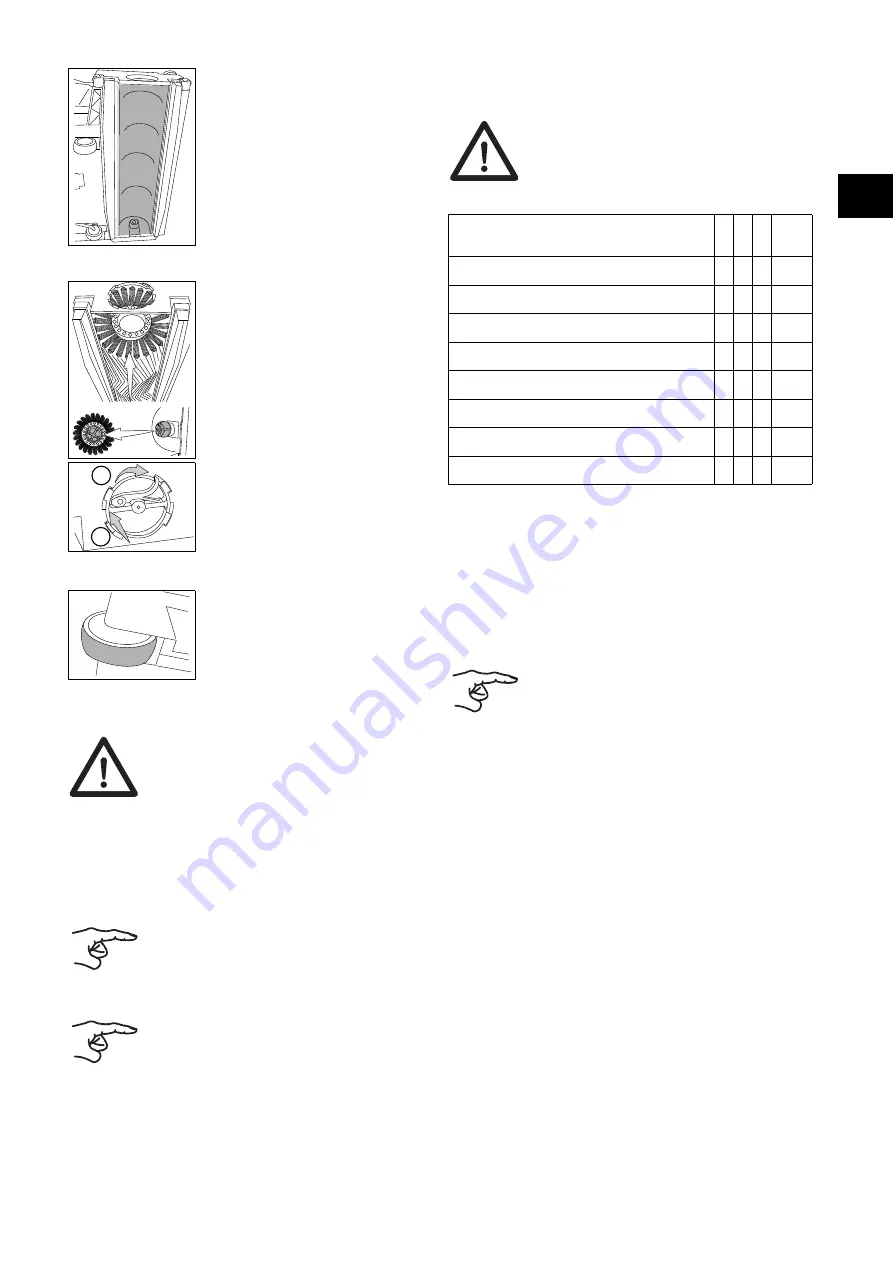

Service, maintenance and care

The maintenance of the machine is a prerequisite for impec

-

cable operation and a long service life.

Service intervals

TASKI machines are high-quality machines that have been

checked for safety in the factory and by authorized inspectors.

Electrical and mechanical parts are subject to wear and aging

after a longer period of use.

Service center

Please always indicate the type and number of the machine

whenever you contact us for order placing or in case of mal

-

functions.

The required data are provided on the nameplate of your ma

-

chine. The address of your closest TASKI service partner is

provided on the last page of these instructions of use.

• Clean the brush housing with a damp

cloth.

• Reinstall the brush roller.

In order to reinstall the brush roller,

you must set the white traveler of the

roller into the white traveler in the

nozzle head. The ribs of the traveler

on the brush roller must be set into

the correct cutouts on the traveler of

the squeegee body.

• Reinsert the brush holder and turn it

clockwise until the rotation lock en

-

gages.

• Before and after every use of the ma

-

chine, clean the running surfaces of

the transport wheels with a damp

cloth.

The transport wheels can become

soiled by transport over the asphalt.

Attention:

Never clean the machine with a high-pres

-

sure cleaner or water jet.

Water ingress in the machine may cause

considerable damage to the mechanical or

electrical parts.

• Wipe the machine with a moist cloth.

Notice:

The machine must be switched off.

Notice:

Store the machine with the tool lifted.

Thus, the tank can dry,

and the generation of mold and unpleas

-

ant odors is prevented.

2

1

Attention:

Use original TASKI parts only; otherwise,

any warranty and liability claims will ex

-

pire.

Activity

◊

◊◊

◊◊◊

Page

Wash out the squeegees

X

61

Clean the brush roller

X

62

Periodically check the length of the bristles

X

Replacing the brush roller

X 62

Suction channel maintenance cover

X

61

Clean/replace the motor protection filter

X

62

Clean the machine with a moist cloth

X

Cleaning the transport wheels

X

63

• In order to maintain operational safety and readiness for

use, the machine must be serviced after 500 working hours

or at least once a year.

Notice:

In case of extraordinary use and/or insuffi

-

cient maintenance, shorter intervals are

required.

EN