F K R - A I N S T R U C T I O N M A N U A L

4

Introduction

FKR-A Series double impulse portable sealers are lightweight and easy to use anywhere. The sealer is

ideal for sealing polyethylene and laminated foils. Equipped with top and bottom heating elements, our

double impulse sealers can seal thicker thermoplastic materials up to 20mil in total thickness.

Applications include sealing around oddly shaped products including drum, box liners or sealing around

large, irregularly sized objects.

Features of the FKR-A Series Double Impulse Portable Sealers

Your sealer is equipped with a wide range of standard features and capabilities.

Impulse sealing - no warm up time needed

Lightweight and easy to operate

Impulse heat with timer

Available in 8", 12", and 16" seal lengths

Seal width: 5mm (.19")

Manufacturer spare parts kit includes: 2 heating elements

How Do FKR-A Double Impulse Portable Sealers Work?

Our FKR-A Series double impulse portable sealers fire a short burst of electricity

through a specially designed heating wire to weld thermoplastic materials together.

The length of the seal time will depend on the sealing characteristics of the bag

being sealed. The sealing process is simple: The operator places the bag between

the sealing jaws and presses the jaws together to activate the unit. The operator retrieves the sealed bag

and repeats the process. Our FKR-A Series double impulse sealers utilize twin heating element wires, one

on the upper sealing jaw and one on the bottom sealing jaw providing greater heat penetration for sealing

through thicker materials (up to 20mil total thickness).

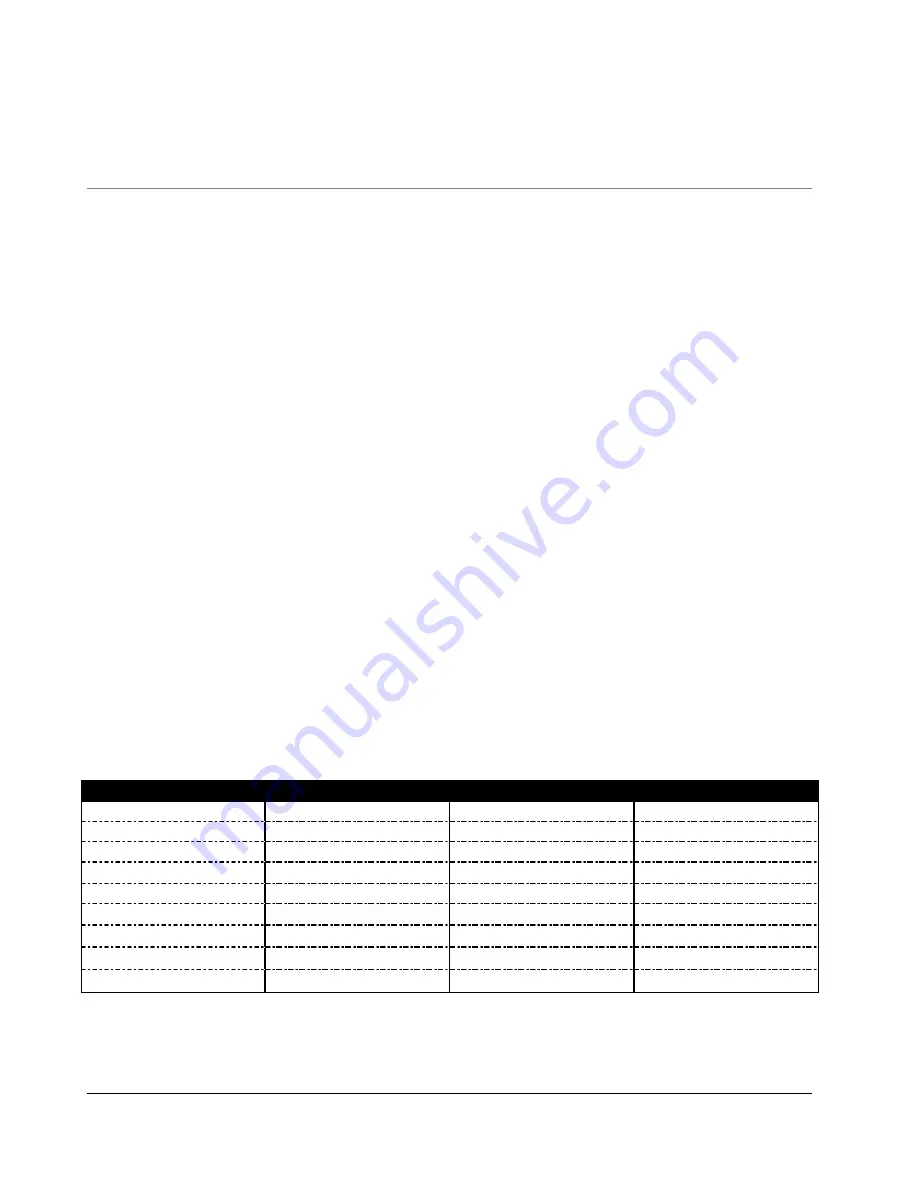

Specifications

FKR-200A

FKR-300A

FKR-400A

Power

110V/60Hz

110V/60Hz

110V/60Hz

Watts

200W

300W

400W

Sealing Length / Width

7.8" / 5mm

11.8" / 5mm

15.7" / 5mm

Power Cord Length

5ft

5ft

5ft

Handle Cord Length

7ft

7ft

7ft

Handle Dimensions

8.9" x 10.2" x 4.7"

13" x 10.2" x 4.7"

17" x 10.2" x 4.7"

Control Box Dimensions

8.7" x 4.9" x 6.9"

8.7" x 4.9" x 6.9"

8.7" x 4.9" x 6.9"

Shipping Dimensions

21" x 14" x 9"

21" x 14" x 9"

21" x 14" x 9"

Gross Weight

15-lbs

19-lbs

20-lbs

Basic

Principles

Place material on lower

jaw and activate by

pressing jaws together