31

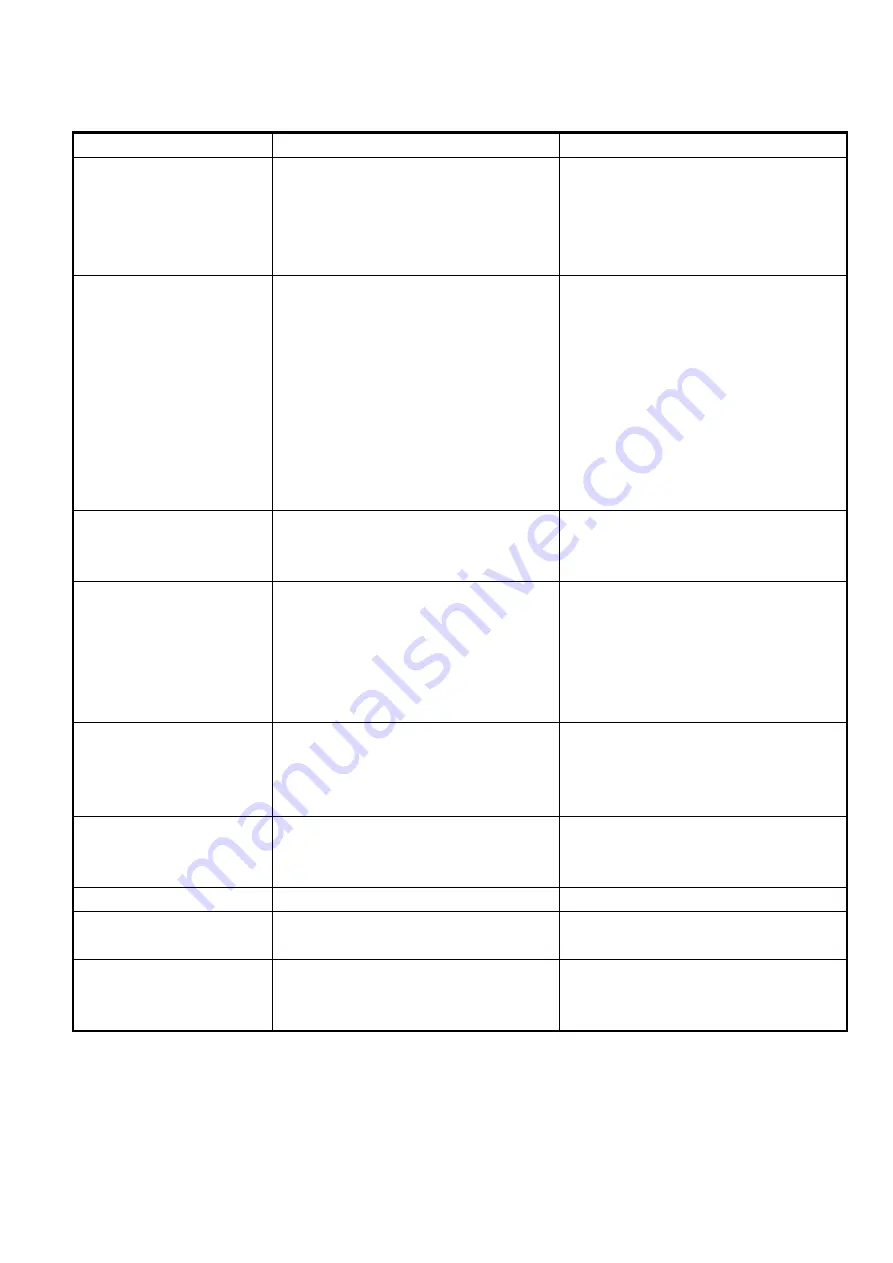

Problem

Reason

Solution

Ink

roller

printing

mechanism doesn’t work

1. The power supply is not connected.

2. Main control PC board is not

inserted in place or poor contact.

3. Main control PC board is damaged.

1. Check whether the power line is

connected and indicating light is on.

2. Check whether plug for PC board is

inserted in place.

3. Check and replace PC board.

Printing wheel doesn’t

work.

1. start sensor’s touching head is

blocked.

2. Start sensor is not clean, whose

hole is blocked by dust.

3. Main control PC board has been

damaged.

4. Round pin on clutch falls off or is

damaged.

5. Electromagnetic c

lutch’s wire is

broken.

1. Clean the obstacle.

2. Clean the dust on sensor’s surface.

3. Check and replace PC board.

4. Repair round pin.

5. Repair clutch.

Printing wheel doesn’t

stop.

1. Sensor (groove sensor) is damaged,

moved, or its surface covered by dust.

2. Main control PC board is damaged.

1. Replace or correct position of

sensor or clean its surface.

2. Check PC board and replace it.

No heat for ink roller

heating block or printing.

1. Heating pipe or wire is damaged.

2. Heating PC board is damaged.

3. The potentiometer on knob is

damaged.

4. Carbon brush seat is not in place.

5. Carbon brush is damaged.

1. Replace heating pipe.

2. Replace PC board.

3. Replace potentiometer.

4. Adjust and tighten nut then.

5. Replace.

The

temperature

of

heating block for ink roller

printing mechanism is out

of control.

The relay for temperature control PC

board is damaged.

Check and replace temperature control

PC board.

The printing position is out

of control.

1. Tightening screw on printing wheel

is loose.

2. Main control PC board is damaged.

1. Tighten the screw.

2.Check and replace PC board.

The speed is a little lower

the speed potentiometer is not exact

adjust the speed switch

The noise of reducer is

risen

replace the greasel of reducer

add #000 great wall extreme pressure

lithium grease

The bag can`t feed to

heating area

the gap between lower and upper

heating block is too small

adjust the switch of upper heating

block and change the pressure of

spring