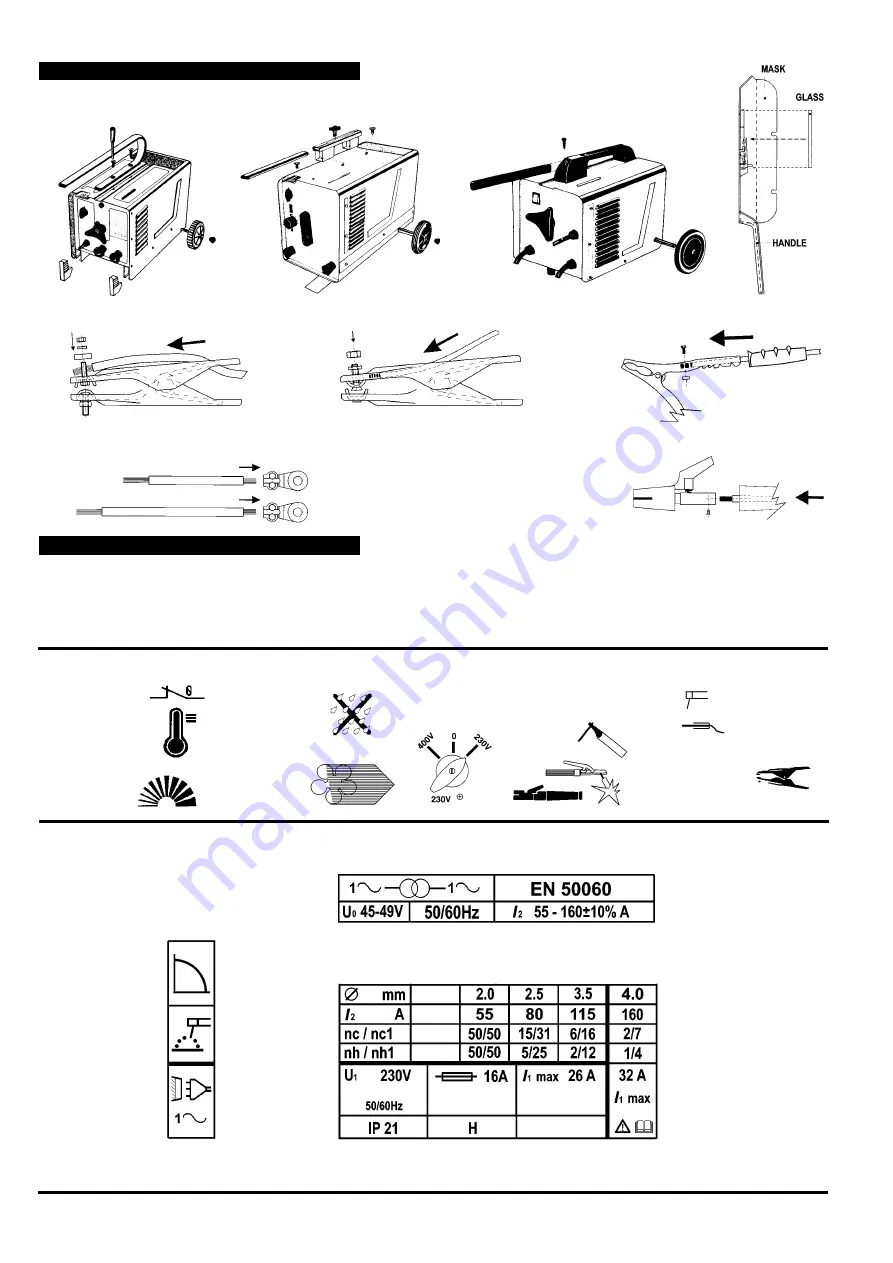

3. ASSEMBLY

4. CONTROLS & SYMBOLS

Unpack the product and check contents. Should there be any damaged or missing parts contact your supplier immediately.

3.1.

Where necessary assembly wheels, handle, feet etc (fig 1a,b,c) and fit the lens inside face mask (fig 2).

3.2. Where necessary assemble the work clamp supplied with your model to the cable associated with the work collet symbol as indicated below.

3.3. Where necessary assemble the electrode holder supplied with your model to the cable associated with the manual arc welding symbol.

(see fig.3). On models with terminal style connections assemble eyelets to cables as shown in fig.4.

The following is to assist you identify your models control panel symbols.

ELECTRO-FAN

Cools the

machine when

running.

THERMOSTATIC

PROTECTION

Lights up when the

machine overheats

and cuts out. The

machine can be used

again when cooled.

SWITCH

POSITION

settings

EARTH

CLAMP

REGULATION

SCALE

RAIN WARNING

SYMBOL

DO NOT

use the

machine in the

rain or snow.

ELECTRODE HOLDERS

various. The electrode holder

is connected to

the machine

via this

outlet,

Manual arc welder

Work Collet

4.1.

Introduction.

Your welder features either a single phase or a three phase transformer with a drooping characteristic suitable for welding with

an alternating current using stick electrodes with diameters from 1.5mm to the highest electrode diameter as described on the data table to

be found on the welders front panel or top cover. The welding current may be regulated by using the screw type stepless welding current

control. The value of the current (1

2

) may be read on the amp graduated scale, this corresponds to the voltage of the arc (U

2

) according to

the equation: U

2

= (18+0,041

2

) V (EN 50060).

Fig 2

Fig 4

Arc Welders - (0051) - (3) - 070601

Symbol for drooping

characteristic.

â

Indicates manual

arc welding with a

covered electrode.

â

Indicates an

alternating current

power supply and 1 to

3 phases as required

by the specification.

â

Diameter of

electrode.

â

Rated

â

welding current.

Rated no load

ã

voltage (min & max)

Welding power source symbol

showing single phase transformer.

ä

British Standard applying

to arc welders

ä

Frequency

ã

of alternating

current

Code letter for

ã

class of insulation.

Rated value of

supply voltage and

its frequency.

â

Max & min rated

ã

value for weld current

á

nh

= no. of electrodes

weldable between restart

and further thermal switch

interruption.

nh1

= no. of electrodes

weldable in one hour when

welder starts at thermal

steady state.

nc

= no. of electrodes

weldable starting at room

temperature until the

thermostat intervenes.

nc1

= no. of electrodes

weldable in one hour when

welder starts at room

á

temperature.

ã

Rated maximum

ã

supply currents

International

â

Standard relating

to moisture ingress

indicating degree of protection.

Mains fuse

required

GUIDE TO RATINGS

PLATE AND SYMBOLS

(For actual ratings of your model

refer to the front panel or top cover.)

FOR ANY FURTHER

CLARIFICATION OF

SYMBOLS REFER TO

BRITISH STANDARD

EN 50060

Fig 1a

Fig 1b

Fig 1c

Fig 3