Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT:

PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

2000ESLE,3000ESLE Issue:2(HF) - 08/02/18

Original Language Version

© Jack Sealey Limited

Refer to instruction

manual

Wear safety

footwear

INSTRUCTIONS FOR:

TROLLEY JACK 2TONNE/3TONNE

EUROPEAN STYLE LOW ENTRY

MODEL No's:

2000ESLE, 3000ESLE

1. SAFETY

Ensure the jack is in sound condition and good working order. Take action for immediate repair or

replacement of damaged parts. Use genuine parts only. The use of unapproved parts may be

dangerous and will invalidate the warranty.

Locate the jack in a suitable, well lit working area.

Keep working area clean and tidy and free from unrelated materials.

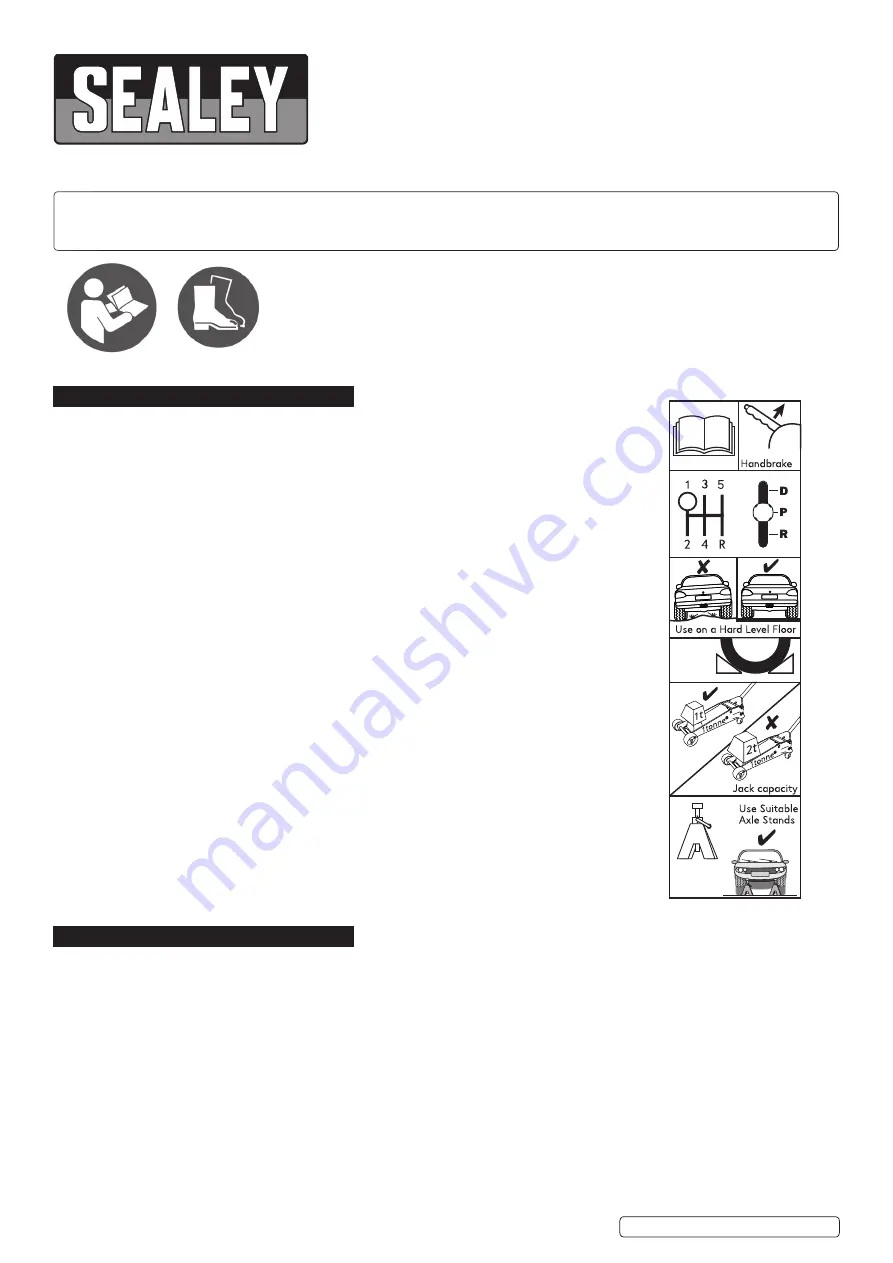

Use jack on level and solid ground, preferably concrete. Avoid tarmacadam as jack may sink in.

Place wedges under wheels of a vehicle, but ensure wheels of jack can move freely.

Ensure the vehicle handbrake is engaged, engine is switched off and transmission is in gear

(or “PARK” if an automatic).

Ensure minimum distance of 0.5m between vehicle and static objects such as doors, walls, etc.,

to allow for vehicle tilting.

Ensure there are no passengers in the vehicle.

Ensure all non-essential persons keep a safe distance whilst the jack is in use.

Only place jack under those lifting points recommended by vehicle manufacturer (see vehicle

handbook).

Check the lifting point is stable and centred on the jack saddle.

Ensure the jack wheels are free to move and that there are no obstructions.

Use suitable capacity axle stands under the vehicle before proceeding with any task.

Ensure there are no persons or obstructions beneath the vehicle before lowering.

Use a qualified person to maintain or repair the jack’s hydraulic system.

DANGER:

Use the jack for lifting only.

DO

NOT

use for supporting the lifted load.

DO NOT

operate the jack if damaged.

DO NOT

allow untrained persons to operate the jack.

DO NOT

exceed the rated capacity of the jack.

DO NOT

allow the vehicle or the jack to move while supported by the jack.

DO NOT

jack the vehicle if there is a risk of spillage of fuel, battery acid, or other dangerous substances.

DO NOT

work under the vehicle until the axle stands have been correctly positioned.

DO NOT

use the jack for purposes other than that for which it is intended.

DO NOT

top up the hydraulic system with brake fluid. Use hydraulic jack oil only.

DO NOT

adjust the safety overload valve.

When not in use store the jack, fully lowered, handle removed in a safe, dry, childproof area.

2. INTRODUCTION

European style trolley jacks manufactured to exacting standards. Lift-and-twist ‘Dead Man’ mechanism operates via ‘D’ shaped handle and

prevents accidental lowering; lowers rapidly without load and provides smooth, slow, controlled lowering with load. Nylon wheels fitted for quiet

operation and prevention of damage to garage floors. Foot pedal for quick lifting of saddle to the vehicle jacking point. Includes removable

rubber saddle pad and built-in tool tray for fasteners and tools. Model No’s 3000ESLE and 2000ESLE feature a low profile lifting arm and

extended access platform for use on low slung vehicles.

.

0.0

Apply

Chock

Wheels

Never

exceed

X2