5. INSTALLATION

p

WARNING: Unplug from mains power supply before connecting cables and accessories.

5.1.

ELECTRICAL CONNECTION.

Ensure the machine is compatible with your electrical mains supply accordingly to electrical safety instructions in section 1.

5.2.

PNEUMATIC CONNECTION.

5.2.1. Connect to an air supply according to section 4.

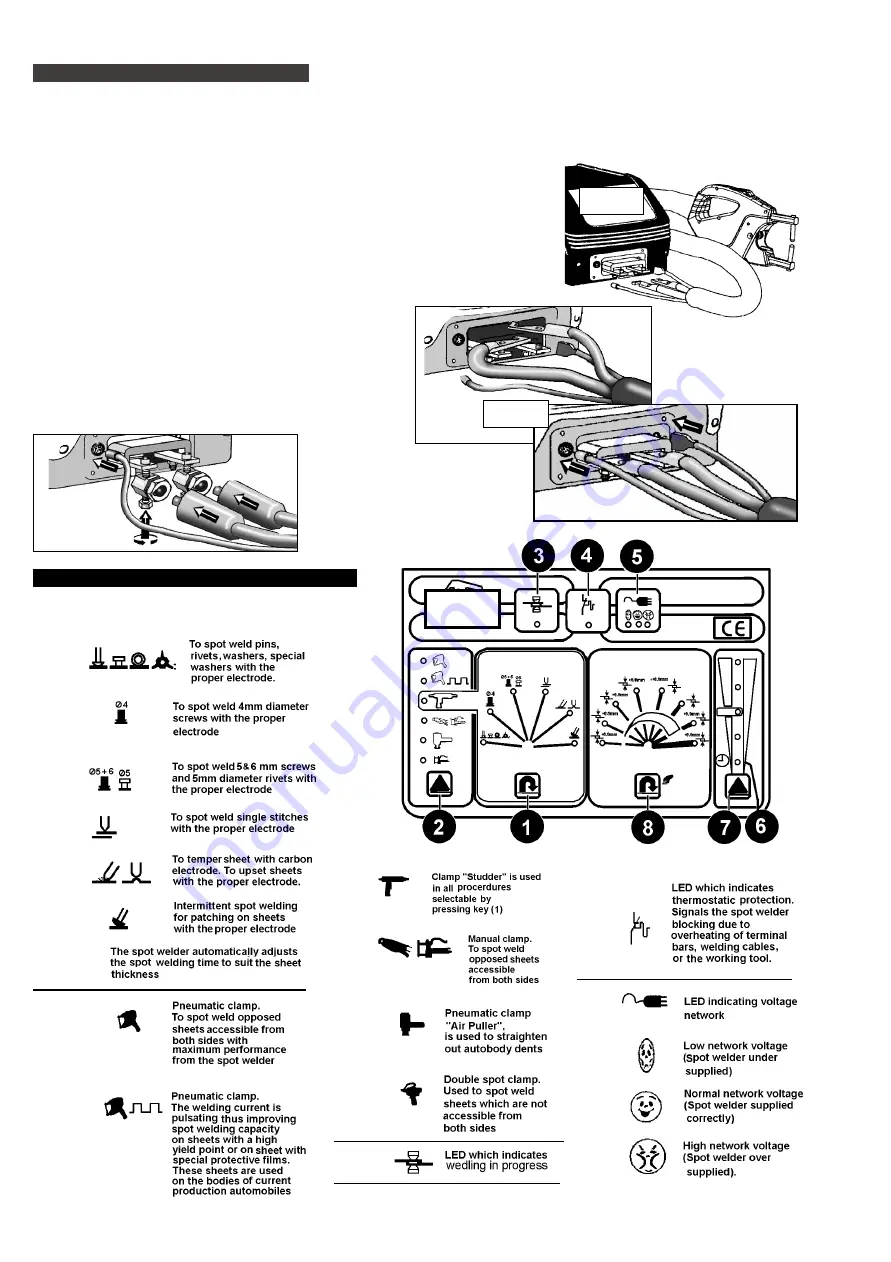

5.2.2. Locate the clamp electrical cable connectors onto pins on welders output terminals (fig 2),

and then rotate cable connectors to hook onto clamps (fig 4).

5.2.3. Tighten clamp bolts with spanner.

5.2.4. Connect the two air lines and the control cable.

5.3.

MANUAL CLAMP, CLAMP STUDDER & GROUND CABLE CONNECTION (fig 3).

5.3.1. Connect DINSE adaptors to welder output terminals.

5.3.2. Plug clamp and ground cable DINSE plugs into DINSE outlets.

5.3.3. Plug in control cable.

5.4.

AIR PULLER & GROUND CABLE CONNECTION (fig 4).

5.4.1. Locate puller and ground cable connectors onto plugs on

welder output terminals and rotate to hook onto clamps.

Tighten clamp bolts with spanner.

5.4.2. Plug in air-line from puller to welder air outlet

and connect control cable.

5.5.

DOUBLE SPOT CLAMP CONNECTION.

Procedure as for Air Puller.

6. READING THE FRONT PANEL

fig 3.

fig 2.

fig 5.

The following describes the function of front panel key

buttons and meaning of symbols, and refers to fig 5.

Key 1.

Key 2.

Key 5.

Key 3.

Key 4.

fig 4.

Electrospot 7000 - 0051 - (1) - 200999