IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE

OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS. USE THIS PRODUCT

CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO

DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE

WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

Thank you for purchasing a Sealey Product. Manufactured to a high standard this product will, if used according

to these instructions and properly maintained, give you years of trouble free performance.

WARNING!

Ensure that Health and Safety, local authority and general workshop practice regulations

are adhered to when using tools.

Ensure that the air brush and accessories are in a clean, sound condition and good working order. Take

action for immediate repair or replacement of damaged parts.

Use recommended parts only. The use of

unauthorised parts may be dangerous and will invalidate the warranty.

Ensure the air brush supply hose is not tangled, twisted or pinched.

DO NOT

use air brush or accessories if damaged.

DO NOT

operate air brush under the influence of drugs, alcohol, intoxicating medication, or if fatigued.

✘

DO NOT

direct spray against yourself, other persons or animals, electrical equipment or the machine itself.

✗

DO NOT

use the air brush for a task it is not designed to perform.

Wear approved eye protection and a suitable respirator when painting. A full range of personal safety

equipment is available from your Sealey Dealer.

✗

DO NOT

allow smoking or open flame in the work area.

INSTRUCTIONS FOR :

AIR BRUSH KITS

MODELS:

AB930 & AB9301

Note:

Numbers in brackets refer to item numbers in the parts diagram.

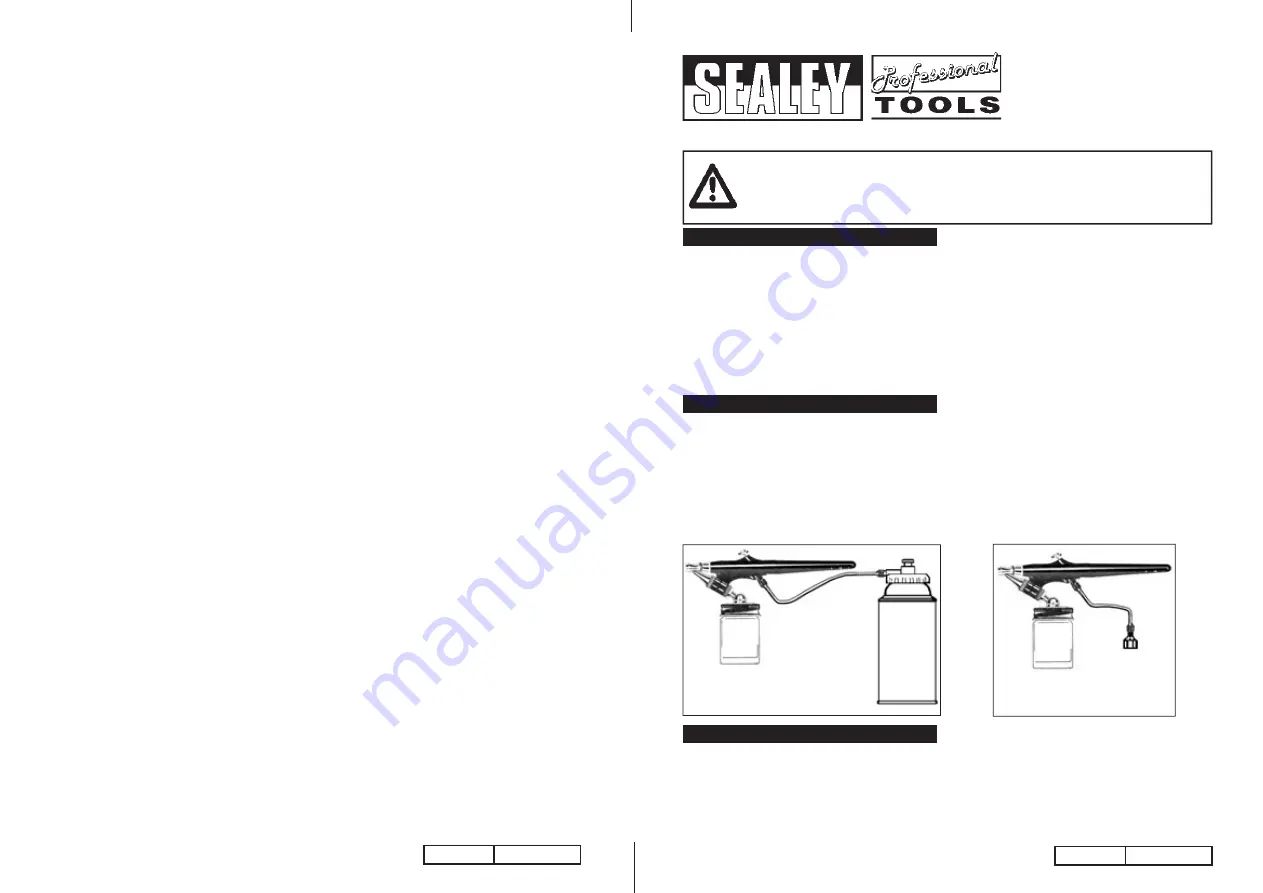

2.1.

Fit the jar adaptor with lid (13) into the fluid needle assembly (24) as shown in fig.1.

2.2.

Screw one end of the hose assembly (19) onto the air hose fitting (10).

2.3.

Screw the other end of the hose (19) to the air supply.

2.4.

When using a compressor (Sealey Model No. AB900), connect the air hose (19) to the air hose adaptor

(supplied with the compressor) before connecting to the compressor, fig.2.

2.5.

When using a propellant can (Sealey Model No. AB/P), connect the air hose (19) to the regulator valve/

cap (11).

2.6.

Ensure the valve is turned fully anti-clockwise before screwing to the top of the propellant can, fig.1.

Fig.1.

Fig.2.

3.1.

Mask the area which is NOT to be painted.

3.2.

Ensure the object to be painted is free from dust, grease and the surface has been prepared

3.3.

After mixing and thinning the paint, as instructed by the paint manufacturer, fill the paint jar just over

half full and screw onto the lid of the jar adaptor lid.

Note:

Mix thoroughly, making sure that the paint is free from lumps. It may be necessary to strain the paint first.

3. OPERATING INSTRUCTIONS

2. ASSEMBLY

1. SAFETY INSTRUCTIONS

AB930 & AB9301

Issue No: 2 - 11/04/08

AB930 & AB9301

Issue No: 2 - 11/04/08