5.3.

OPERATING THE AUTO VALET MACHINE

p

p

WARNING! Test materials for colour fastness, test on an area not normally noticed (i.e. under a car seat).

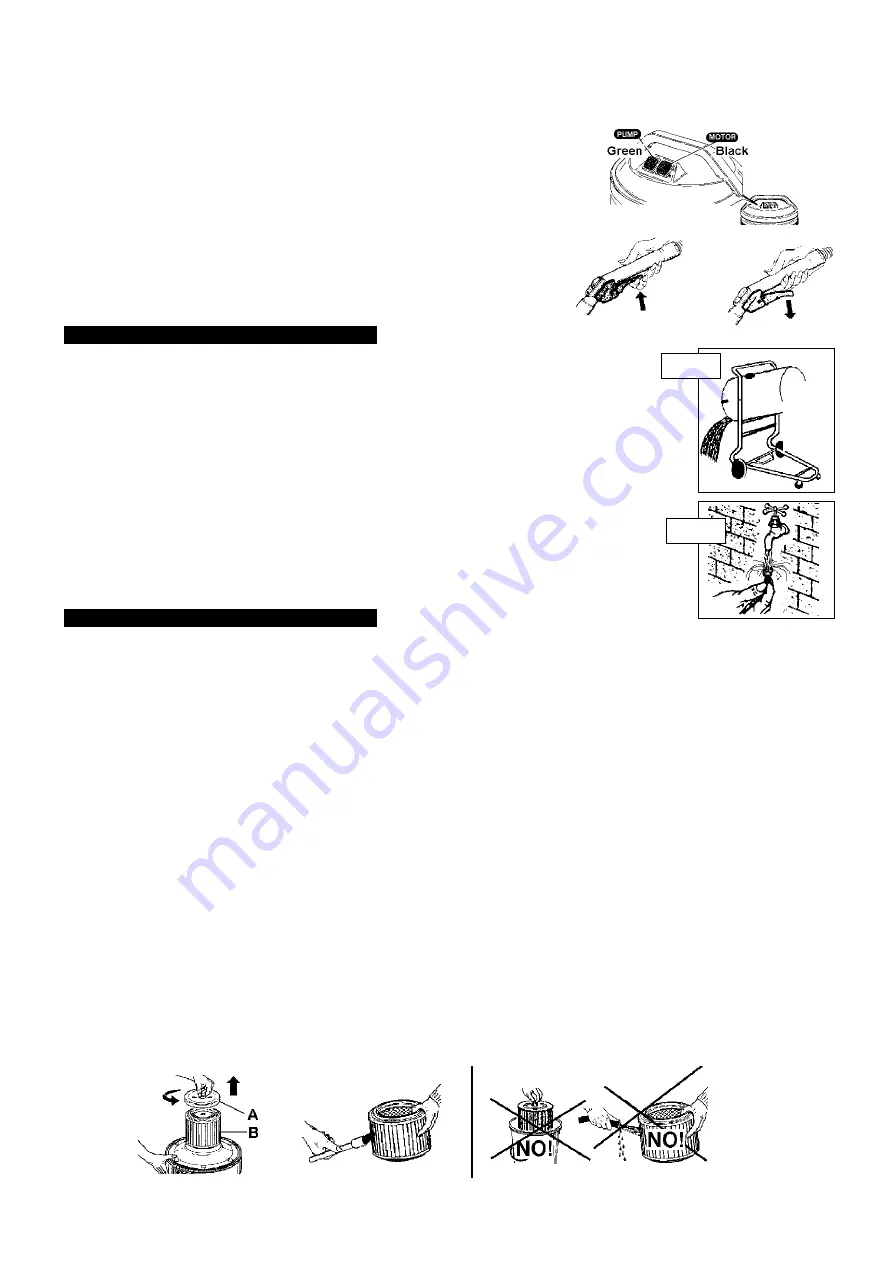

5.3.1. Plug the machine into the mains power supply.

5.3.2. Switch the

BLACK MOTOR SWITCH ON

to start the vacuum (fig 20).

DO NOT PRESS THE PISTOL TRIGGER AT THIS STAGE.

5.3.3. Place the cleaning head on the material to be cleaned and press the

GREEN PUMP SWITCH ON

(fig 20).

5.3.4. Press the trigger (fig 21) and move the tool slowly across the material by drawing

the head towards you. Work in small areas at a time. The pump produces pressure which

forces detergent into the fabric pile. During this first pass approximately 60% of the

dirty fluid will be sucked back up into the waste tank.

5.3.5. Make a second pass

WITHOUT

pressing the trigger (fig 22). This will extract

the remainder of the fluid from the material, leaving the fabric almost dry.

5.3.6. Allow the fabric, or upholstery to dry completely before walking, or sitting on it.

fig 20

fig. 21

fig. 22

6.1.

Remove the plug from the mains.

6.2.

Remove the motor head.

6.3.

Empty tank of dirty liquid by steadying the trolley and lifting the tank to empty content into an appropriate

waste receptacle or drain (fig 23). Take care to maintain balance and not let the trolley slip.

6.4.

Empty and rinse out the detergent tank.

6.5.

Fill the detergent tank with clean water, and flush the system by operating into a bucket, or drain.

Continue to flush until all the dirty fluid has been expelled.

6.6.

Rinse the tank clean.

6.7.

Wipe the tank and fittings and leave to dry.

6.8.

Check the filter at the end of the detergent pick-up pipe to ensure it is not clogged.

If it is, remove and rinse under running water (fig 24).

6.9.

Remove the main motor head filter and clean as in chapter 7.

NOTE:

Before next use, check that the correct filter is fitted for the job you are going to perform.

Use of wrong filter will invalidate your warranty.

fig 23

fig 24

6. AFTER USE

p

p

WARNING ENSURE YOU DISCONNECT FROM THE MAINS POWER SUPPLY BEFORE OPENING THE UNIT, OR CARRYING OUT ANY MAINTENANCE.

7.1.

General Machine Maintenance.

7.1.1. Remove plug from the mains power supply before carrying out service or maintenance.

7.1.2. Regularly check and clean the filter connected to the end of the detergent pick-up pipe by running under a cold water tap (fig 24).

7.1.3. After having used the appliance as a wet cleaner, empty the contents. Clean and dry the tank and accessories to avoid scaling.

7.1.4. Periodically check to ensure the valet machine, and accessories are not blocked, or damaged, and in good working order.

Any damaged parts must be replaced immediately. Blocked hoses or tubes will impair performance and may damage the machine.

Such damaged motor units returned for repair will not be accepted under the warranty, and may incur expensive repair bills.

7.2.

Cleaning Filters.

For optimum performance, all types of filters should be cleaned regularly. Unclean, damaged, or wrongly fitted filters will impair your

machines performance and may damage it. Such damaged motor units returned for repair will not be accepted under the warranty, and

may incur expensive repair bills. Never use the machine without a filter. Dirt in motor will cause failure and will invalidate the warranty.

7.2.1. CLEANING FOAM FILTER.

Used for wet cleaning.

a)

Wash the foam filter in a suitable container of lightly soapy water (DO NOT use solvents).

b)

Allow to dry before use. Check to see if the filter is worn, in which case it must be replaced with a new one.

7.2.2. CARTRIDGE FILTER CLEANING.

Used for dry cleaning.

a)

Remove the filter cartridge from the motor head (fig 25).

b)

Regularly clean the cartridge filter by dusting with a soft bristle brush (fig 26).

c)

DO NOT

get the filter wet or wash filter in water or any other cleaning liquids as the filter will disintegrate (fig 27).

NOTE:

Inspect filters regularly, if large amounts of un-removable deposits are obvious, or if the filter is worn or damaged it must be replaced.

7. MAINTENANCE

Steady

the

trolley

whilst

lifting

tank

fig 25

fig 26

fig 27

VMA9133 - 3 - 031003