Declaration of Conformity

We, the sole importer into the UK, declare that the products listed below are in conformity with

the following EEC standards and directives.

The construction file for these products are held by the

Manufacturer and may be inspected on request by contacting

Jack Sealey Ltd

AUTOMIG190, AUTOMIG210, AUTOMIG235,

AUTOMIG250, AUTOMIG190ARC,

& AUTOMIG260ARC

73.23/EEC

Low Voltage Directive (S.I. 1994/3260)

89/336/EEC

EMC Directive (S.I. 1992/2372 & Amendments).

1st February 1999

J. Sealey

.

Jack Sealey Ltd.

Sealey Power Welders.

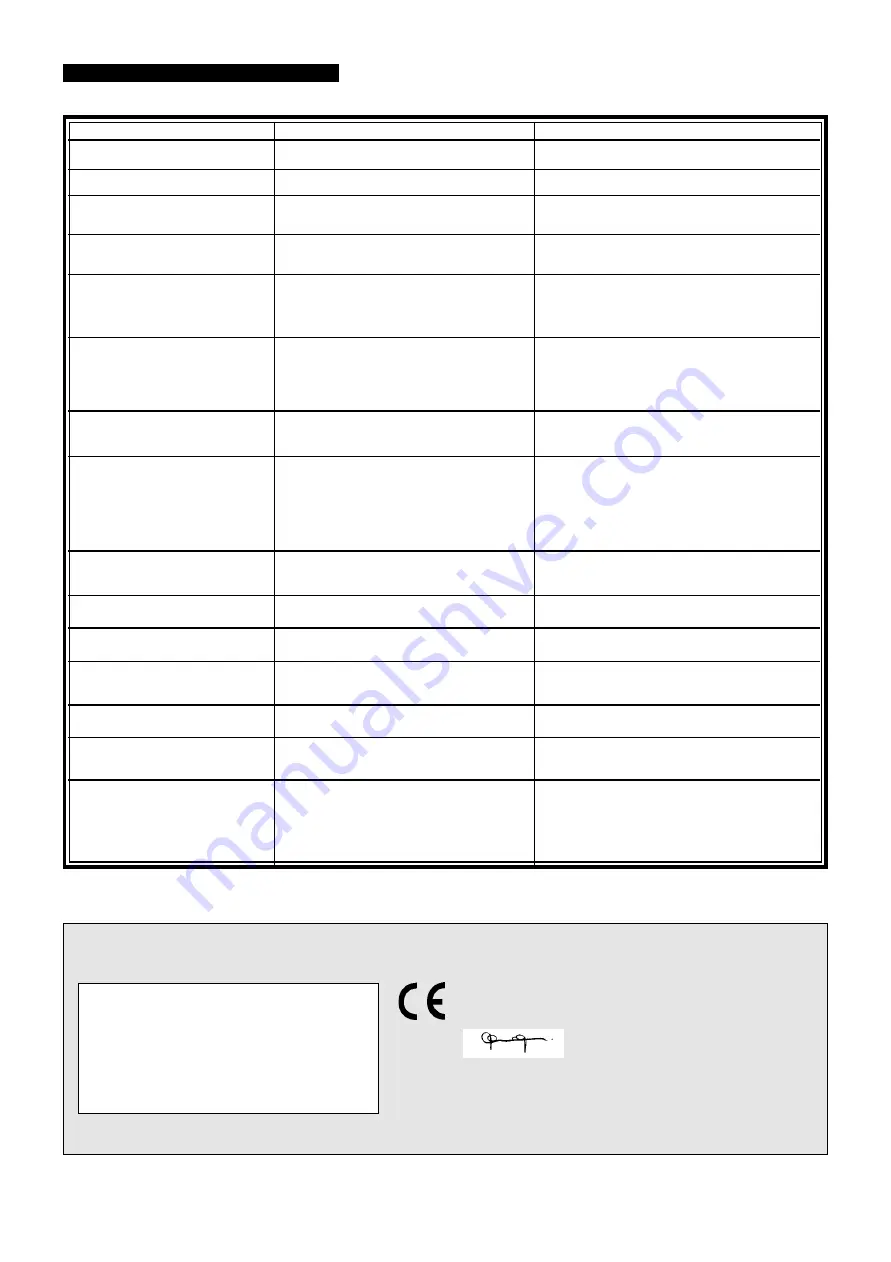

1. Power source stops

2. No weld current, fuse blowing in 13amp plug

3. No weld current

4. Feed motor not working, lamp is on

5. Wire does not feed, feed roller rotates

6. Wire feeds unevenly.

7. Unstable arc.

8. Porous weld

9. Electrode sticking in contact tip or gas cup

(nozzle)

10. Irregular weld head

11. Weld bead too narrow and raised

12. Weld bead too wide

13. Poor penetration

14. Excessive penetration

15. Fuse blowing

Overheating protection activated due to overload

Rectifier blown

Bad connection between clamp & workpiece

Break in earth lead

Break in torch lead

Fuse blown

Gear damaged or worn

Motor defective

Pressure roller improperly adjusted

Dirt, copper, dust, etc, have collection in torch liner

Gas cup (Nozzle) defective

Deformed wire

Dirt, etc, in liner

Gas cup (Nozzle) or contact tip defective

Gas cup (Nozzle) spattered

Feed roller groove clogged

Feed roller groove deformed

Wrong tension

Incorrect settings

Impurities in weld area

Worn or defective gas cup (nozzle)

No gas

Gas cup clogged

Draft blowing away shielding gas

Rusty or dirty joints

Torch too far from or at wrong angle to work

Gas leak

Worn or defective gas cup (nozzle)

Electrode deformed

Wire speed too slow

Torch incorrectly held

Wire weaving in weld pool

Weld current too low

Weld speed too low

Weld current too high

Weld speed too low

Arc too long

Weld current too low

Arc too long

Weld current too high

weld speed too slow

incorrect distance of torch to workpiece

Tension too great

Gas cup contact tip clogged

PROBLEM

POSSIBLE CAUSE

REMEDY

(Numbers refer to chapter and item heading)

7. TROUBLESHOOTING

Protection automatically resets when transformer has cooled

(about 15 min).

Replace rectifier.

Clean or grind contact surface and weld area.

Repair or replace earth lead.

Repair or replace torch.

Replace fuse 1.5 amp. (Chapter 6).

Replace gears. (Chapter 6).

Replace motor (Contact service agent).

Adjust tension. (Chapter 3).

Clean the liner from the machine forward. Use compressed air.

If too much dirt, replace the liner. (Chapter 6).

Replace gas cup (nozzle) and check tip. (Chapter 6).

Check pressure roller tension and adjust it if necessary. (Chtr 3).

Clean the liner from the machine forward. Use compressed air.

Replace gas cup (nozzle) or contact tip. (Chapter 6).

Clean or replace gas cup (nozzle). (Chapter 6).

Clean feed roller. (Chapter 6).

Replace feed roller. (Chapter 6).

Adjust tension. (Chapter 3).

Adjust settings.

Clean or grind weld area. (chapter 4).

Replace gas cup (nozzle) and check tip. (Chapter 6).

Open gas cylinder, regulate gas flow.

Clean or replace cup. (Chapter 6).

Screen off welding site or increase gas flow.

Clean or grind.

The distance from gas cup to workpiece should be 8-10mm

and torch angle 60

0

.

Check hoses, connections and torch assembly. (Chapter 6).

Press the gas cup in correction position.

Replace gas cup (nozzle). (Chapter 6).

Check pressure roller tension. (Chapter 3 & 6).

Increase wire speed.

Use torch angle 60

0

. (Chapter 5).

Check pressure roller tension, adjust as needed. (Chapter 3).

Increase voltage and wire speed. (Chapter 4).

Move torch slower and weave a little more.

Decrease voltage and wire speed. (Chapter 4).

Move torch faster and weave less.

Bring torch closer to workpiece.

Increase voltage and wire speed. (Chapter 4).

Bring torch closer to workpiece.

Decrease voltage and wire speed. (Chapter 4).

Move torch faster.

Torch distance should be 8-10mm. (Chapter 5).

Release tension. (Chapter 3).

Clean gas cup and contact tip. (Chapter 6).

AUTOMIGS 190,210,235,250, 190ARC & 260ARC - (0095) - (1) - 010299