5.1.

Pre-use Inspection.

WARNING!

INSPECT THE GRINDER BEFORE USE. ENSURE THE GRINDER IS UNPLUGGED FROM THE MAINS POWER

BEFORE COMMENCING THE INSPECTION.

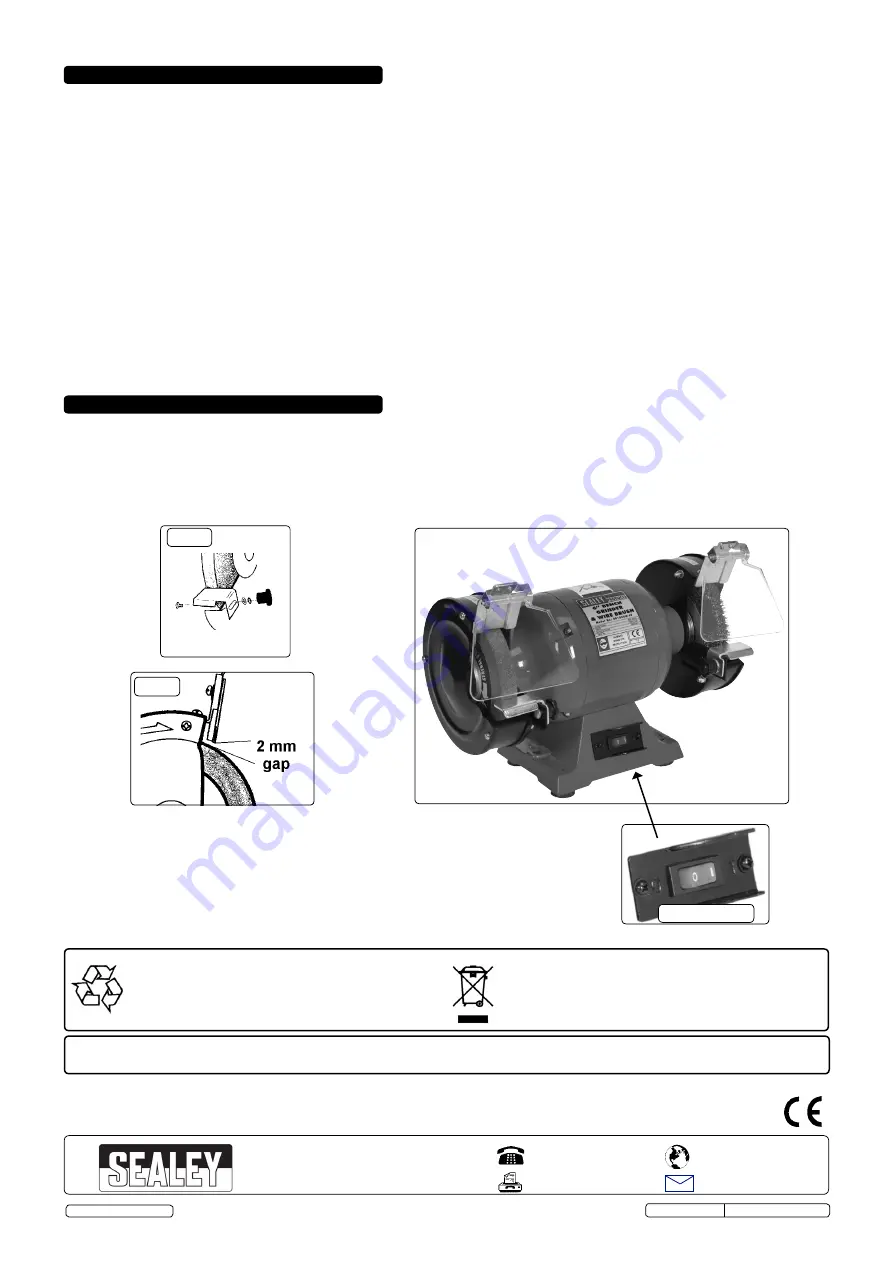

5.1.1. check the tool rests are securely fixed and are not more than 2mm from the grinding wheel and approximately 2mm from wire wheel

tines.

5.1.2. check that eye shields are in good condition, secure and that you can see through them clearly.

5.1.3. turn the grinding wheel by hand and check for any damage. check neither wheel touches the tool rests and are correctly aligned.

If any of the above checks fail, replace, repair, or adjust as necessary before starting the grinder.

5.2.

Wheel Use.

the grinder is supplied with one aluminium oxide wheel, one wire wheel.

If the surface of the wheel becomes “loaded” (coated with particles of the material being ground) it is probably the wrong grade for the

job.

Important reminder:

Only a person holding a grinding wheel certificate may install wheels. See Section 4.

5.3.

Using the Grinder.

WARNING!

before commencing work, ensure you read, understand and apply the Section 1 Safety Instructions.

5.3.1. Plug grinder into the mains power supply.

5.3.2. Adjust the eyeshield to give maximum protection.

5.3.3. switch on the grinder and bring the workpiece slowly into contact with the rotating wheel.

5.3.4. When the task is complete unplug the grinder from the mains power supply and clean the machine ready for next use.

6. MAINTENANCE

WARNING!

Ensure the grinder is unplugged from the mains power supply before performing any maintenance or service.

6.1.

As the wheels wear, adjust the positions of the tool rests. rests must be set not more than 2mm from the grinding wheel surface

and approximately 2mm from the wire brush tines surface.

6.2.

regularly remove the wheel covers and clean out any dust and dirt.

6.3.

the machine motor and bearings are sealed units and require no regular maintenance. should you require assistance, contact your

local service agent.

5. OPERATING INSTRUCTIONS

noTE:

It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT:

no liability is accepted for incorrect use of this product.

WARRANTY:

Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION:

for a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

01284 757500

01284 703534

sales@sealey.co.uk

Sole UK Distributor, Sealey Group,

Kempson Way, suffolk Business Park

,

Bury st. Edmunds, suffolk,

IP32 7Ar

www.sealey.co.uk

Web

Original Language Version

© Jack sealey Limited

fitting spark

arrestor

fig. 4

fig. 5

Parts support is available for this product. To obtain a parts listing and/or diagram,

please log on to www.sealey.co.uk, email sales@sealey.co.uk or telephone 01284 757500.

Environmental Protection.

recycle unwanted materials instead of disposing of them as

waste. All tools, accessories and packaging should be sorted,

taken to a recycle centre and disposed of in a manner which

is compatible with the environment.

WEEE Regulations.

Dispose of this product at the end of its working life in compliance

with the Eu Directive on Waste Electrical and Electronic Equipment.

When the product is no longer required, it must be disposed of in an

environmentally protective way. contact your local solid waste

authority for recycling information.

shielded switch

BG150XW/99.V2 Issue: 2(L) - 03/03/14