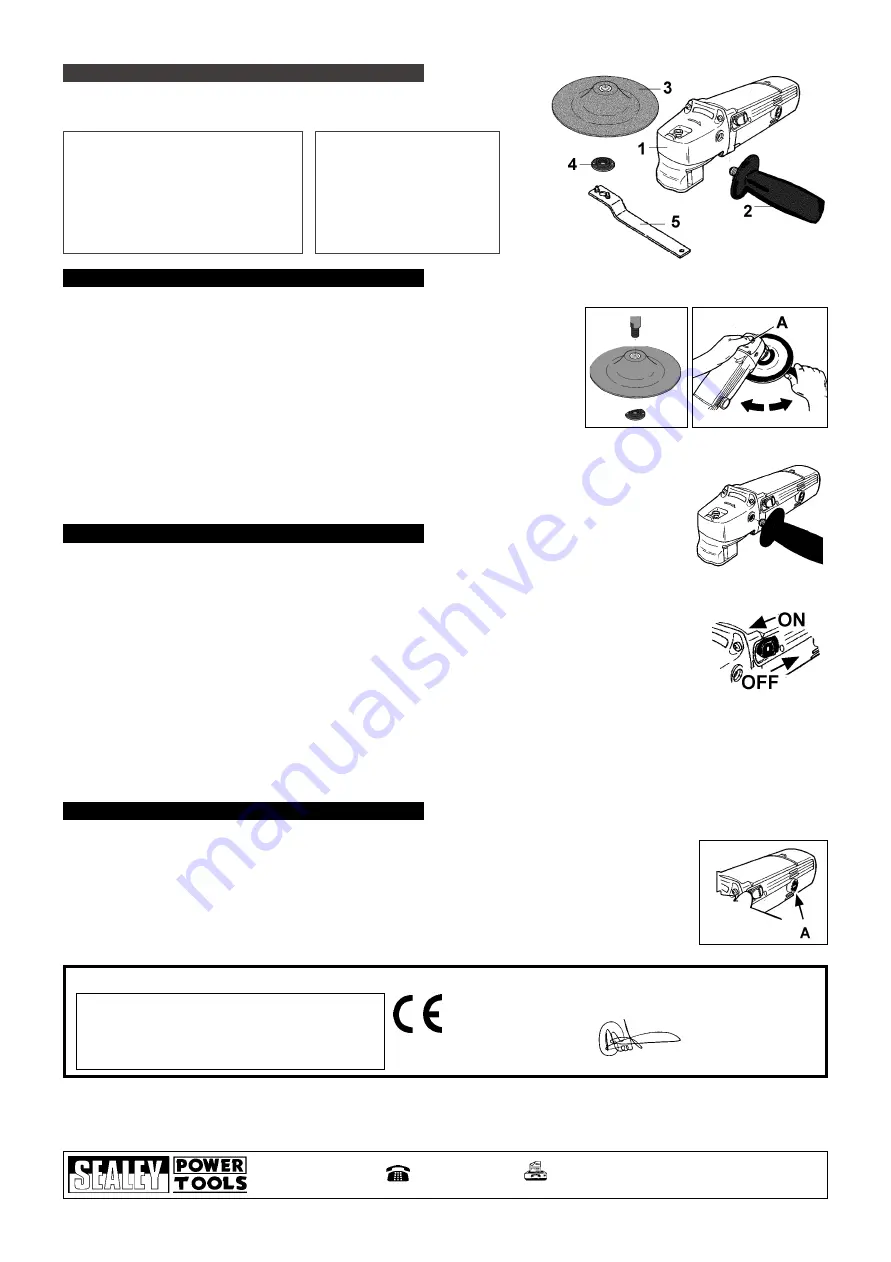

CONTENT LIST

1.

Main body.

2.

Handle grip.

3.

Rubber backing pad.

4.

Lock nut.

5.

Pin wrench.

3. PACKAGE CONTENT & SPECIFICATION

fig 1

p

WARNING!

ensure the polisher is unplugged from the mains power supply before assembling.

4.1.

Fitting Backing Pad

4.1.1. Screw the rubber backing pad (fig 2) on the centre spindle ensuring the funnel shape

flange is facing toward the machine head.

4.1.2. To secure pad, screw on the lock nut (with flange facing in toward the pad).

4.1.3. Stop the spindle from turning by pushing in and holding the stop button (fig 3.A).

4.1.4. Lock backing pad into place by tightening lock nut with the wrench (fig 3).

4.1.5. When complete, release the locking button and check that it has sprung back to its initial position.

p

WARNING!

DO NOT use backing pads that are damaged or thought to be damaged.

Once mounted on the polisher, test the pad before use by facing the polisher in a safe direction (point away from yourself, others and vulnerable

items) and run for a short time.

s

DANGER! The use of damaged pads is dangerous and may cause personal injury.

4.2.

Hand Grip

The hand grip gives better control. Screw into appropriate hole on left or right hand side of the head (fig 4).

4. ASSEMBLY

Remove items from packing and identify parts against fig 1. Check to ensure they

are in good condition. If any part is damaged contact your supplier immediately.

SPECIFICATIONS

Power . . . . . . . . . . . . . . . . . . .800W

No load speed . . . . . . . . . . .1700rpm

Shaft thread . . . . . . . . . . . .M14 x 2.0

Weight . . . . . . . . . . . . . . . . . .1.96kg

Sound pressure level . . . . .88.7dB(A)

Sound power level . . . . . . .95.6dB(A)

p

WARNING!

Ensure polisher is unplugged from the mains power supply before changing accessories.

Check that the polisher switch is not in the ON position.

Before polishing ensure you are wearing approved safety goggles, ear defenders, appropriate dust mask, if polisher generates dust,

and safety gloves and that all other safety instructions in Section 1 are followed carefully.

5.1.

Preparation

5.1.1. Fit the backing pad according to 4.1. and position handle grip conveniently for the task.

5.1.2. Fit polishing bonnet (not supplied) to backing pad and then plug polisher into the mains power supply.

5.2.

ON/OFF Switch

Switch is spring loaded into Off position for positive cut-off and reduced possibility of accidental starting (fig 5).

5.2.1. Once plugged into the mains power supply start the polisher by pushing the switch forward.

5.2.2. To switch machine off press down rear of switch. The machine will stop and the switch will be in the safez position.

5.3.

Polishing

The key to effective polishing is controlling the pressure and surface contact between the disc and the workpiece.

DO NOT switch the polisher on whilst the bonnet is in contact with the workpiece. Bring the rotating bonnet to the workpiece.

5.3.1. Allow the polisher to reach full speed before starting to polish.

5.3.2. When work is finished, unplug the polisher from the mains power supply, clean and store in a safe, dry, childproof area.

5. OPERATING INSTRUCTIONS

fig 5

ER1700P - 0016 - (3) - 230501

fig 4

fig 2

fig 3

6.

MAINTENANCE

p

WARNING!

Ensure the polisher is disconnected from the mains power supply before attempting any maintenance.

6.1.

Cleaning

Keep polisher ventilation slots clean and free from obstructions. If available, blow compressed air into

the vents to clear any internal dust (safety goggles must be warn when undertaking this process). Keep

outer case of polisher clean and free from grease. DO NOT wash with water or use solvents or abrasives.

6.2.

Changing the brushes

6.2.1. Remove the two brush caps, one from each side of the polisher (fig 6.A).

6.2.2. Remove the brushes, replace with a new set and refit brush caps.

fig 6

01284 757500

E-mail:

sales@sealey.co.uk

01284 703534

Sole UK Distributor,

Sealey Group,

Bury St. Edmunds, Suffolk.

Declaration of Conformity

We, the sole importer into the UK, declare that the product listed below is in conformity with the following standards and directives.

The construction file for this product is held by the Manufacturer and may

be inspected, by a national authority, upon request to Jack Sealey Ltd.

For Jack Sealey Ltd. Sole importer into the UK of Sealey Power Tools.

Signed by Mark Sweetman

Date 27th April 2001

HEAVY DUTY 170mm POLISHER

Model ER1700P

73.23/EEC Low Voltage Directive

89/336/EEC EMC Directive

NOTE:

It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT:

No responsibility is accepted for incorrect use of this product.

WARRANTY:

Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION:

For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your name and address, including post code.