2. introduction

composite cover moulded around lightweight aluminium alloy housing reduces effects of chill on operator’s hands and provides added control.

Air motor with quality bearings for smooth and powerful operation. fitted with safety release trigger control to prevent accidental operation.

Exhaust outlet adjusts 360° keeping air flow away from operator. Supplied with Ø50mm pad and installation spanner.

3. sPeciFication

model no: ....................................................................GsA70

Pad size: ...................................................................

Ø50mm

thread size: .......................................................... m6 x 1mm

motor power: ................................................................. 0.3hp

free speed: ............................................................ 15000rpm

orbit size: ....................................................................

Ø3mm

Air consumption: ............................................................ 4cfm

operating pressure: ...................................................... 90psi

inlet size: ...................................................................1/4”BsP

Weight: .......................................................................... 0.7kg

noise power/pressure: ....................................... 101/90dB(A)

Vibration/uncertainty: ......................................... 4.5/2.25m/s²

4. PreParation For use

4.1.

air supply

4.1.1.

ensure the sander air valve (or throttle) is in the “off” position before connecting to the air supply.

4.1.2.

You will require an air pressure between 70-90psi, and an air flow according to the specification above.

WarninG!

ensure the air supply is clean and does not exceed 90psi while operating the sander.

4.1.3.

too high an air pressure and/or unclean air will shorten the product life due to excessive wear, and may be dangerous, causing damage

and/or personal injury.

4.1.4.

drain the air tank daily. Water in the air line will damage the sander and will invalidate your warranty.

4.1.5.

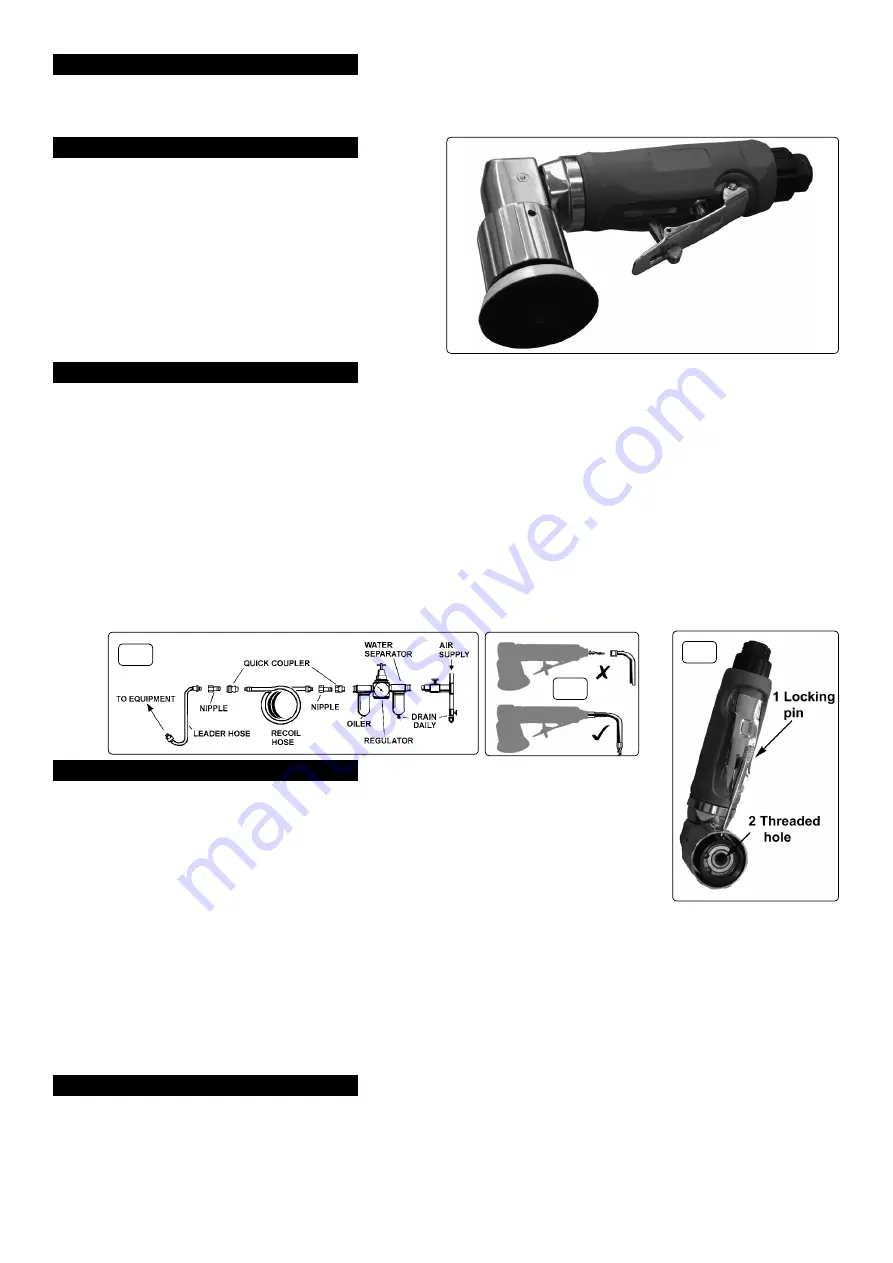

clean air inlet filter weekly. recommended hook-up procedure is shown in fig.1.

4.1.6.

line pressure should be increased to compensate for unusually long air hoses (over 8 metres).

4.1.7.

the minimum hose diameter should be 1/4” i.d. and fittings must have the same inside dimensions.

4.1.8.

Keep hose away from heat, oil and sharp edges. check hoses for wear and make certain that all connections are secure.

4.2.

couplings

4.2.1.

Vibration may cause failure if a quick change coupling is connected directly to the air sander. to overcome this, connect a leader hose

to the sander. A quick change coupling may then be used to connect the leader hose to the air line recoil hose.

See figs.1 & 2.

5. oPeration

WarninG!

ensure you read, understand and apply the safety instructions in section 1 before use.

5.1.

assembly

5.1.1.

To fit the backing pad you must first lock the rotating head using the locking pin. Rotate the head until

the locking hole is visible through the aperture in the outer shroud. insert the pin as shown in fig.3-1.

5.1.2.

screw the backing pad into the threaded hole in the head (see fig.3-2) and tighten. remove the locking

pin. use only discs with speed ratings equal to or higher than the speed rating of the sander.

8

do not

use cloth backed sanding discs.

5.1.3.

connect air supply to sander, press the control valve lever and check that the sander is working

correctly.

5.1.4.

The air flow may be regulated by adjusting the regulator valve in the

back of the handle.

5.2.

operation

5.2.1.

the sander is designed to provide a combined “rotary” and “random orbit” action. Always use a grit appropriate for the job. Work

progressively from coarse grades to finer grades.

8

do not

go from coarse to fine in one step as it may be difficult to

remove swirl marks left by the coarse grit.

8

do not

apply excessive pressure, let the sander do the work for you. start the sander and bring the sanding disc to the work surface

evenly and slowly. move the sander back and forth in overlapping areas. remove the sanding disc from the work surface before

stopping the sander. regularly check the sanding disc for wear, always change if cracked or damaged.

8

do not

allow sander to run in “idle rotation” for an extended period of time, as this will reduce bearing life.

6. maintenance

WarninG!

disconnect sander from air supply before changing accessories, servicing or performing maintenance.

replace or repair

damaged parts.

Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

6.1.

if the air supply does not have an oiler lubricate the air sander daily with a few drops of good grade air tool oil such as sealey Ato/500

or Ato/1000, dripped into the air inlet before use.

6.2.

clean the sander after use and change pads when required.

6.3.

loss of power or erratic action may be due to the following:

fig.1

fig.2

fig.3