Ideal for the garage or bodyshop where space is limited. Suitable for pre-MOT inspection and fulfils the legal obligation of the garage

or bodyshop to return vehicles to the customer in roadworthy condition. Compact design includes shortened mast and view through

aiming device. Suitable for all types of cars, motorcycles and light commercial vehicles (Classes I, II, III, IV, V, VII).

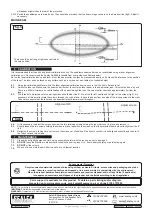

A Base

B Column

C

Release Lever

D

Light Box

E Aligner

F

Retaining Handle

4.1.

Attach the 3 wheels to the base (A) of the unit using long

bolts (axles), washers and nuts.

4.2.

Attach base of column (B) to base of unit, using four sets

of bolts, washers and nuts. Column should be positioned so

that two holes in top of column base are in line with wheels.

4.3.

Position mid section into column base and fix in place using

two countersunk headed allen bolts.

4.4.

Slide the beam setting light box (D) over the top of the

column, squeezing the release lever (C) first. Release the

release lever to lock the light box onto the column.

4.5.

Insert retaining handle (F) through top of column B, place a

washer then the aligner (E) onto the threaded end and

tighten.

1.1. GENERAL SAFETY

WARNING!

Ensure Health & Safety, local authority, and general workshop practice regulations are adhered to when using this equipment.

DO NOT

use the Beam Setter in direct sunlight.

DO NOT

splash the Beam Setter with water or any other liquid.

DO NOT

operate the Beam Setter if it is damaged.

DO NOT

use the Beam Setter for purposes other than that for which it is designed.

Avoid sudden changes in temperature.

Avoid sudden vibration.

Keep work area clean and tidy and free from unrelated materials.

Ensure the vehicle handbrake is engaged

Ensure there are no passengers in the vehicle.

When not in use store Beam Setter in a safe, dry, childproof location.

IMPORTANT

: This Beam Setter uses a fixed graduated screen in accordance with the requirements of the MOT regulations.

However it must be noted that the HBS2010.V2 is

NOT

approved by VOSA for conducting tests in accordance with MOT requirements.

fig.1

Original Language Version

HBS2010.V2 Issue: 2 - 07/01/16

© Jack Sealey Limited

INSTRUCTIONS FOR:

HEADLAMP BEAM SETTER - COMPACT

MODEL NO:

HBS2010.V2

IMPORTANT:

PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE THE PRODUCT

CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL

INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instrutions,

and properly maintained, give you years of trouble free performance.

1. SAFETY

2. INTRODUCTION

3. SPECIFICATION

4. ASSEMBLY

Refer to

instruction

manual

Height: . . . . . . . . . . 1380mm

Width:. . . . . . . . . . . . 630mm

Length: . . . . . . . . . . . 550mm