4.7.

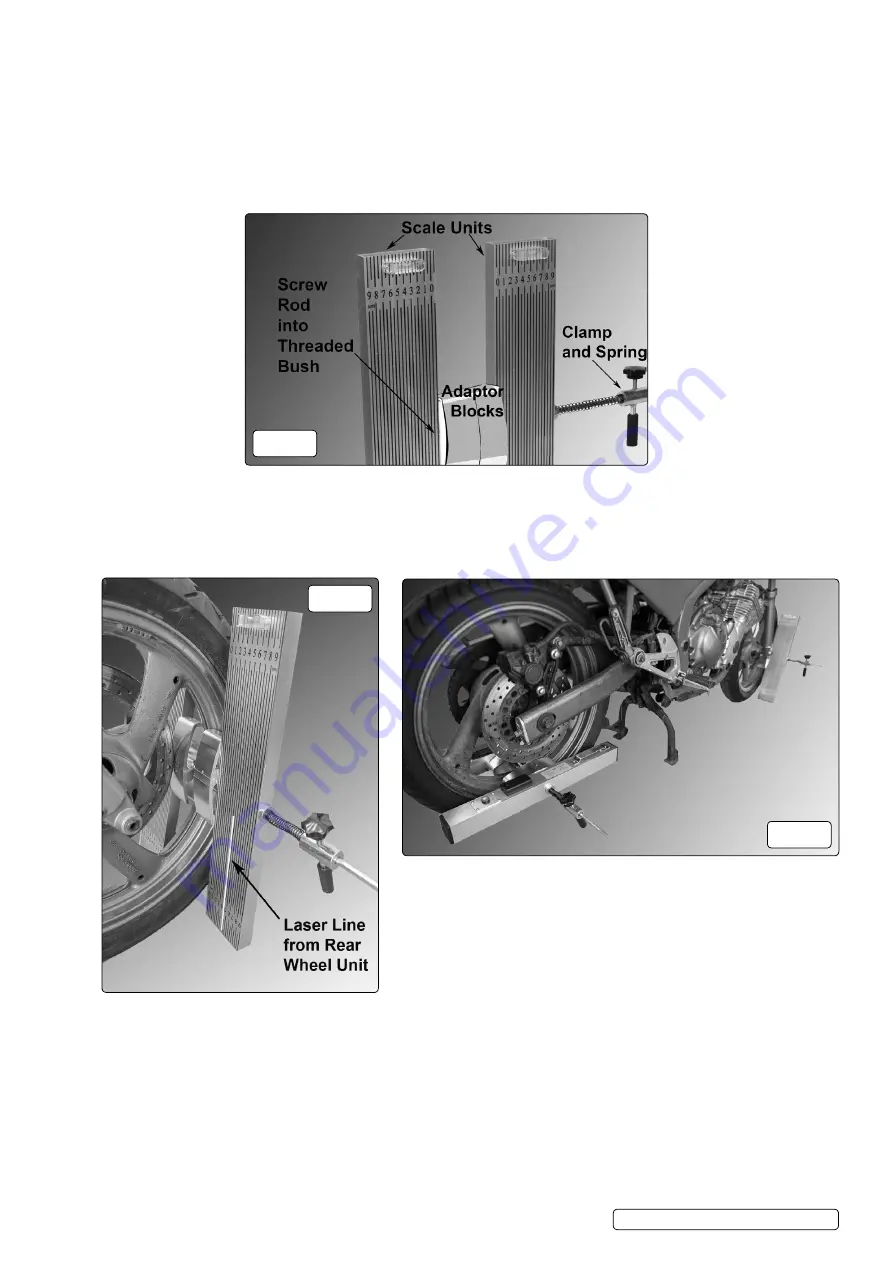

Attaching the scale units to the front wheel:

Referring to fig.5, loosen the clamp and remove the clamp unit and spring from the

rod together with the right hand scale unit. Position the left hand scale unit with the rod attached on the nearside of the front wheel

in a near vertical orientation and insert the rod through the adaptor and then through the front part of the wheel. Slide the right hand

adaptor and scale unit onto the rod and up to the tyre, followed by the spring and clamp the two units lightly to the wheel using the

adaptors on the wheel rim to space the laser unit away from the tyre in the position indicated in fig.6.

4.8.

Switch on the lasers and note the position of each beam on the scales. If necessary, adjust the position/angle of the laser units on

the rear wheel to get the beams to appear on the scales.

4.9.

Front wheel position: The front wheel must be in the straight ahead position before accurate alignment can take place. If the beams

are parallel with the scale lines the front wheel is set dead ahead. If the beams are at an angle to the scale lines, turn the wheel

one way or the other until they are parallel.

4.10.

AlignMent ProceDure

4.11.

Compare the readings on the scales. If they are the same then the rear wheel is in alignment with the front wheel. If they are not

the same then it will be necessary to operate the rear wheel adjusters. If the reading is higher on the right hand scale, tighten the

left hand adjuster. If the reading is higher on the left hand scale, tighten the right hand adjuster. When the wheels are in alignment,

finally tighten the rear wheel axle fixings.

fig.5

fig.6

fig.7

MS070.V2 Issue 2 (H4F) 25/05/18

Original Language Version

© Jack Sealey limited