p

WARNING!

Ensure the drill is unplugged from the mains power supply before commencing.

6.1.

Install drill bit

6.1.1.

Insert drill bit into chuck jaws to 1" (25mm) deep (avoid inserting small bits too far) and centre bit in chuck before tightening.

6.2.

Adjusting the table

6.2.1.

To adjust table up or down, loosen the clamp bolt (fig.2.B) then turn the bracket handle (fig.2.A).

6.2.2.

To adjust table tilt, loosen the work table bolt (fig.2.C), adjust to the desired angle using the angle scale, then retighten bolt.

6.2.3.

To turn the table around the column, loosen the rack collar slightly, then loosen the clamp bolt (fig.2.B).

Turn the table to the desired position then secure the bolt and the rack collar.

6.3.

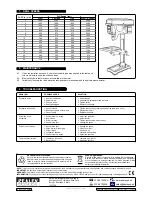

Adjusting the speed

6.3.1.

Open the pulley case and loosen the belt tension lock screws (fig.6.A) - one either side of head.

6.3.2.

Choose the speed for drilling operation (see drill speed chart - Section 7) and move the belts to the

correct position for that speed, as shown on the chart inside the pulley cover.

6.4.

Belt tension

6.4.1.

With the belt tension lock screws (fig.6.A) loose and using hand pressure on the adjusting handle

(fig.5.C), set tension so that belt give is no more than 1/2" (13mm). Tighten lock screws.

6.5.

Positioning the workpiece

6.5.1.

Use a piece of wood to rest the workpiece on. The drill bit may break through the workpiece and damage the table otherwise.

The wood should rest on the table so that one end of it is against the left side of the column, to prevent it spinning when the drill bit

breaks through the workpiece.

6.5.2.

For small workpieces that cannot be clamped to the table, use a drill vice (not included). Vice must be clamped or bolted to table.

6.6.

Setting the drill depth

6.6.1.

Use the scale on the side of the drill head near the drill handle.

6.6.2.

Loosen locking screw (fig.5.D) and set the scale to the depth desired. Tighten locking screw.

6.6.3.

When ready to drill, simply pull the feed handle. The drill will stop at the set depth.

6.7. Illumination

(PDM155B only)

6.7.1.

The workpiece illumination is controlled by the rocker switch located immediately above the main power switch on the front of the

head.

6. OPERATING INSTRUCTIONS

Note: Figures are illustrative and may differ in detail from your drill.

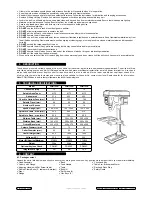

5.1. Assembly

5.1.1. Place the column assembly on the base, align holes and secure with the bolts provided.

5.1.2. Install table bracket onto column together with rack (fig.1), engaging gear in bracket with rack.

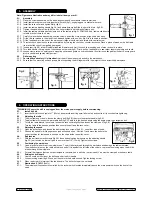

5.1.3. Install the rack collar and tighten firmly (fig.2).

5.1.4. Install the table adjusting handle (fig.2.A) and pivoted clamp bolt (the longer of the two - fig.2.B).

5.1.5. Tighten the handle set screw (with the hex. key provided) and the bracket clamp bolt.

5.1.6. Install the table and table pivoted clamp bolt to the table arm(fig.3). PDM100B only - table bolts directly

to table bracket, there is no arm.

5.1.7. Carefully place the head assembly over the column and slide it into position. Align head with base.

5.1.8. Fit the two set screws in the side of the head and tighten with hex. key (fig.4) to lock head in position.

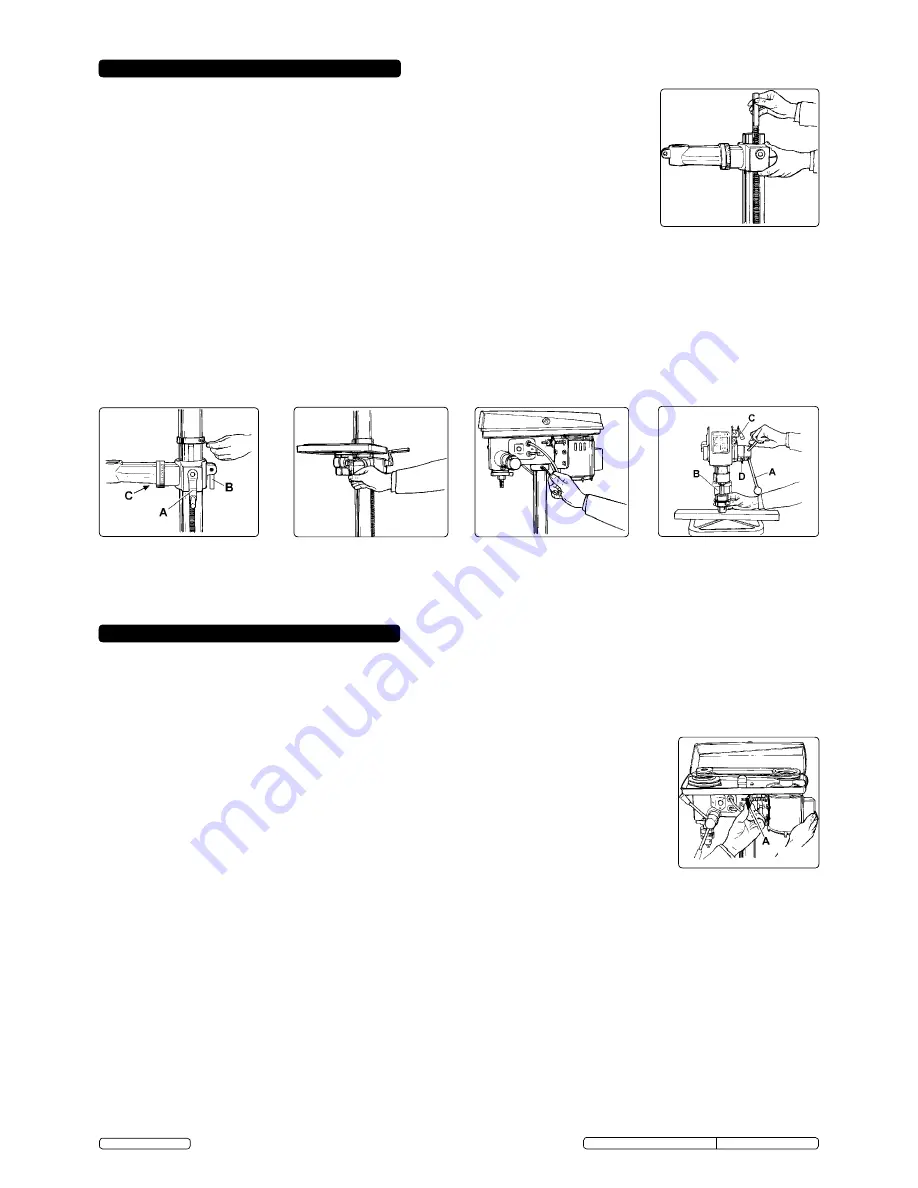

5.1.9. Fit the feed handle to the hub of the pinion shaft (align pin with slot) and retain with central screw.

5.1.10. To install chuck open the chuck jaws completely by turning the chuck key counter-clockwise. Place a piece of wood on the drill table

(to prevent the chuck from getting damaged).

5.1.11. Insert arbor (fig.5 B) into drill spindle (reduced diameter end first), fit chuck to protruding end of arbor and hold in place.

5.1.12. Turn feed handle to bring nose of chuck down onto wood (fig.5). Firmly pull on feed handle to seat arbor tapers in spindle and chuck.

5.1.13. Loosen clamp screw on safety guard mounting collar, pass guard up over chuck and fit collar round flange of quill shaft. Ensure guard

pivot is central and tighten clamp screw.

5.2.

Drill mounting

5.2.1.

For stability and safety it is important

that the drill base is securely bolted to the workbench.

5.2.2. Ensure that the mounting surface is capable of supporting the drill together with the weight of the heaviest likely workpiece.

5. ASSEMBLY

fig. 1

fig. 2

fig. 3

fig. 4

fig. 5

fig. 6

Original Language Version

PDM100B, PDM125B, PDM155B Issue: 4 (SP) - 10/12/13

© Jack Sealey Limited