4.4.

WHEN WORK IS COMPLETE.

At the end of each working day, drain any moisture from the main tank. Place a container

under the drain plug and then carefully unscrew it (fig.5).

DO NOT

allow moisture to

accumulate in the tank as this will corrode the inside of the tank and affect the pressure

rating of the tank.

WARNING!

Wear safety goggles when performing this task.

5. MAINTENANCE

fig.4

fig.9

In order to keep the compressor in good working condition, periodic maintenance is essential.

IMPORTANT! Failure to carry out maintenance tasks may invalidate the warranty on your compressor.

WARNING! Service and maintenance must be performed by an authorised agent. DO NOT tamper with, or attempt to adjust, the

pressure switch or safety valve. Before moving, or carrying out any maintenance on the compressor, ensure that the ignition switch

is ‘off’, that the air tank pressure has been vented and the compressor has been allowed to cool down for a period of time.

5.1. ENGINE.

For all engine maintenance, please refer to the engine manufacturer’s handbook (supplied) for the full schedule.

5.2. COMPRESSOR.

5.2.1.

Operations to be carried out after the first 50 working hours:

a)

check that all bolts/nuts are tight, particularly those retaining the crank case and cylinder head.

b)

Replace the lubricating oil - see para 5.2.5.

5.2.2.

Operations to be carried out daily:

a)

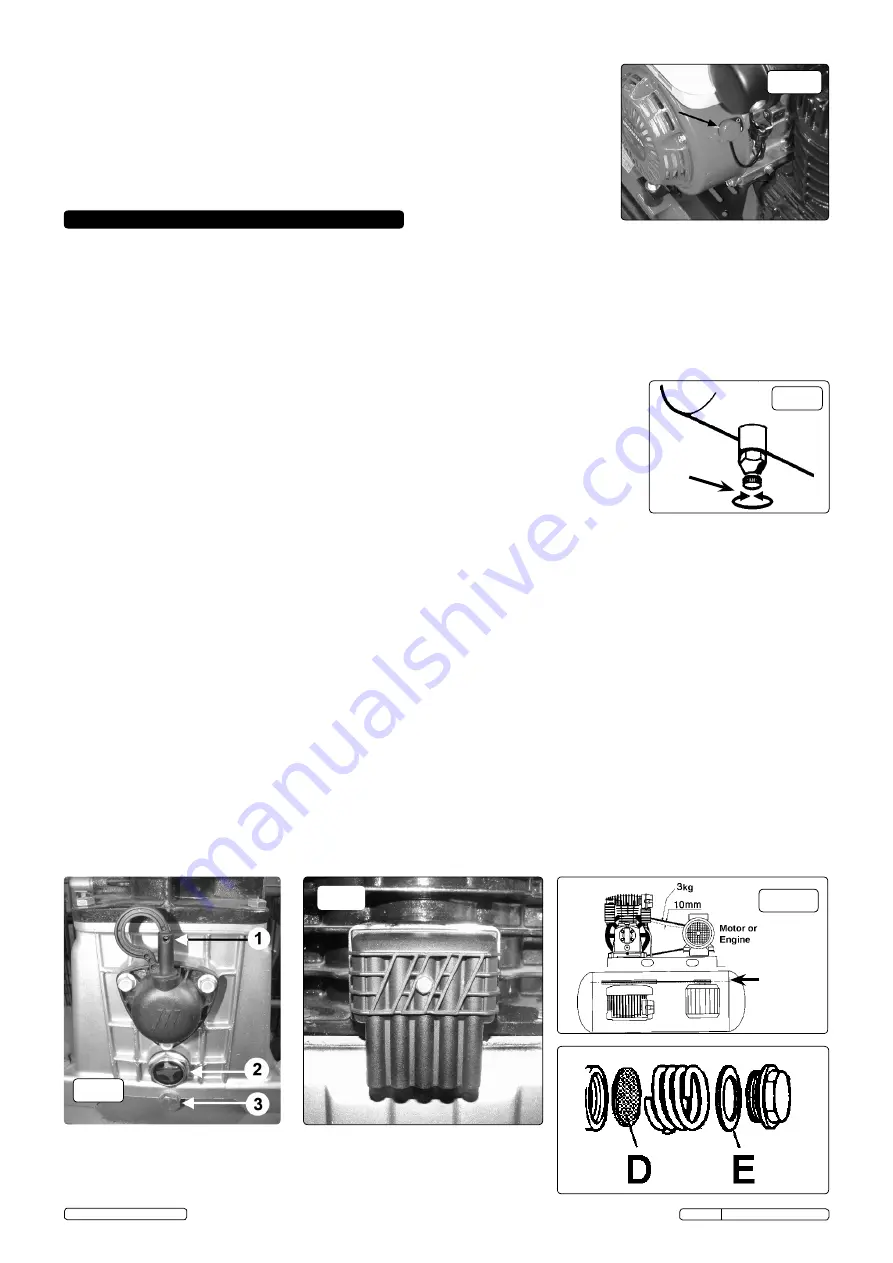

Drain condensation by opening the valve (fig.5) located under the tank.

b)

check oil level (fig.6.2) and, if necessary, top-up.

c)

check guards/covers are secure.

d)

check for oil leaks.

e)

check for unusual noises or vibrations.

f)

check for air leaks.

5.2.3.

Operations to be carried out weekly:

a)

(or more frequently, if the compressor operates in a very dusty atmosphere):

Remove the air filter element by undoing the bolt and removing the filter cover (fig.7). clean the filter by blowing through from

the clean side, with an air line at low pressure. Replace filter, cover and bolt. Do not operate compressor without filter as

foreign bodies or dust could damage the pump.

WARnInG! Wear safety goggles when performing this task.

b)

clean compressor.

c)

check the automatic cut-out operation at maximum pressure and the automatic cut-in at 2 bar below.

5.2.4.

Operations to be carried out monthly:

a)

check belt tension. A weight of 3kg applied at the belt mid-point should give a deflection of approximately 10mm (fig.8). If

adjustment is required, maintain the alignment of the two pulleys (fig.8). Adjust by repositioning the engine, using the

screw adjuster provided in the base plate.

5.2.5.

Operations to be carried out every 200 working hours:

a)

change air filter element.

b)

Replace the lubricating oil. For oil specifications see 5.4.

Remove the oil breather (fig.6.1) and (after placing a suitable container under it) the oil drain bolt (fig.6.3). Drain when the

compressor has been recently run, so that the oil drains rapidly and completely. Replace the oil drain bolt and refill

through the filler aperture. Do not overfill.

Replace the oil breather.

WARNING! Never mix different oils and do not use non-detergent/low quality oils as the compressor

may be

damaged.

WARNING! Dispose of waste oil only in accordance with local authority requirements.

c)

check all tube fittings and electrical connections.

d)

Inspect pressure tank inside and out for damage or corrosion.

It is recommended that every two years (or approximately every 1600 working hours), the compressor is returned to an

authorised dealer for a complete inspection.

ALIGNMENT

fig.5

fig.6

fig.8

fig.7

Original Language Version

SA5055 Issue: 2 (SP) - 23/08/13

© Jack Sealey Limited 2013