2.1.

ELECTRICAL SAFETY

WARNING!

It is the responsibility of the owner and the operator to read, understand and comply with the following:

You must check all electrical products, before use, to ensure that they are safe. You must inspect power cables, plugs, sockets and any

other connectors for wear or damage. You must ensure that the risk of electric shock is minimised by the installation of appropriate

safety devices. A Residual Current Circuit Breaker (RCCB) should be incorporated in the main distribution board. We also recommend

that a Residual Current Device (RCD) is used. It is particularly important to use an RCD with portable products that are plugged into a

supply which is not protected by an RCCB. If in any doubt consult a qualified electrician. You may obtain a Residual Current Device by

contacting your Sealey dealer.

You must also read and understand the following instructions concerning electrical safety.

2.1.1.

The Electricity at Work Act 1989

requires that all portable electrical appliances, if used on business premises, are tested by a

qualified electrician, using a Portable Appliance Tester (PAT), at least once a year.

2.1.2.

The Health & Safety at Work Act 1974

makes owners of electrical appliances responsible for the safe condition of those

appliances and the safety of the appliance operators. If in any doubt about electrical safety, contact a qualified electrician.

2.1.3.

Ensure that the insulation on all cables and on the appliance is safe before connecting it to the power supply. See 1.1.1. and 1.1.2.

and use a Portable Appliance Tester.

2.1.4.

Ensure that cables are always protected against short circuit and overload.

2.1.5.

Regularly inspect power supply cables and plugs for wear or damage and check all

connections to ensure that none is loose.

2.1.6.

Important: Ensure that the voltage marked on the appliance matches the power supply to

be used and that the plug is fitted with the correct fuse - see fuse rating at right.

2.1.7.

DO NOT

pull or carry the appliance by the power cable.

2.1.8.

DO NOT

pull the plug from the socket by the cable.

2.1.9.

DO NOT

use worn or damaged cables, plugs or connectors. Immediately have any faulty

item repaired or replaced by a qualified electrician. When a BS 1363/AUK 3 pin

plug is damaged, cut the cable just above the plug and dispose of the plug safely.

Fit a new plug according to the following instructions (UK only).

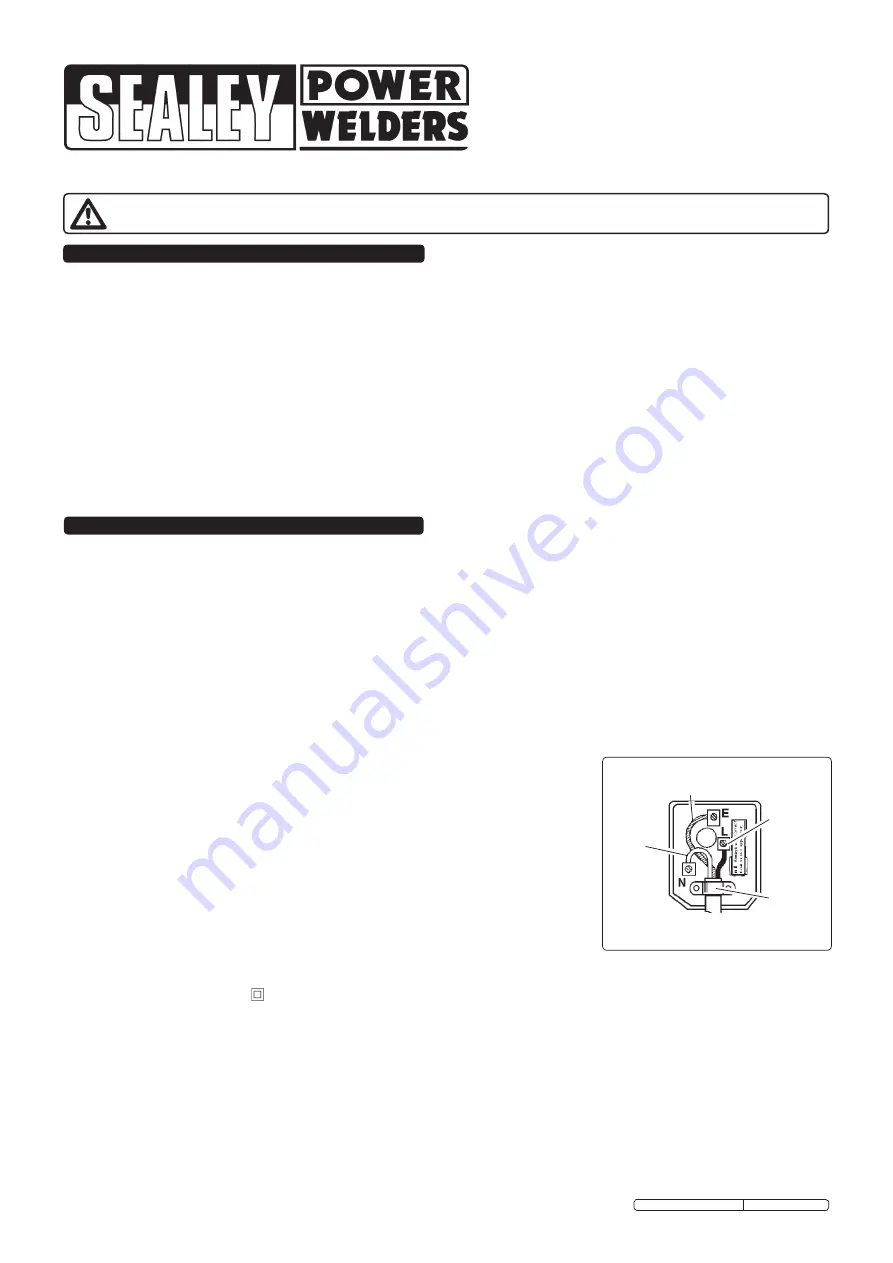

a)

Connect the GREEN/YELLOW earth wire to the earth terminal ‘E’.

b)

Connect the BROWN live wire to the live terminal ‘L’.

c)

Connect the BLUE neutral wire to the neutral terminal ‘N’.

d)

After wiring, check that there are no bare wires, that all wires have been correctly connected, that the cable outer

insulation extends beyond the cable restraint and that the restraint is tight.

Double insulated products, which are always

marked with this symbol

,

are fitted with live (brown) and neutral (blue) wires only. To rewire, connect the wires as indicated

above.

DO NOT

connect either wire to the earth terminal.

2.1.10. Products which require more than 13 amps are supplied without a plug. In this case you must contact a qualified electrician to

ensure that a suitably rated supply is available. We recommend that you discuss the installation of an industrial round pin plug and

socket with your electrician.

2.1.11. If an extension reel is used it should be as short as possible and fully unwound before connection. A reel with an RCD fitted is

preferred since any appliance plugged into it will be protected. The cable core section is important and should be at least 1.5mm²,

but to be absolutely sure that the capacity of the reel is suitable for this product and for others which may be used in the other output

sockets, we recommend the use of 2.5mm² section cable.

INSTRUCTIONS FOR:

PLASMA INVERTERS

MODELS:

PP25.V2, PP25PLUS.V2

Thank you for purchasing a Sealey plasma inverter. Manufactured to a high standard this product will, if used according to these instructions and properly

maintained, give you years of trouble free performance.

IMPORTANT

:

BEFORE USING THIS PRODUCT, PLEASE READ THE INSTRUCTIONS CAREFULLY. MAKE CAREFUL NOTE OF SAFETY INSTRUCTIONS, WARNINGS

AND CAUTIONS. THIS PRODUCT SHOULD ONLY BE USED FOR ITS INTENDED PURPOSE. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL NJURY

AND WILL INVALIDATE THE WARRANTY. RETAIN THESE INSTRUCTIONS FOR FUTURE USE.

2. SAFETY INSTRUCTIONS

The PP25 and PP25PLUS are inverter power supplies fitted with plasma inverter control circuitry. Features include an LED information panel

covering torch under voltage, air fault, general fault (thermostat, over/under voltage, over current) and power on. PP25PLUS has a built-in

compressor, making it a self-contained unit. The plasma inverters are suitable for cutting steel, stainless steel, aluminium, copper and brass.

PP25 includes an integrated air filter and regulator with pressure gauge.

When the torch trigger is depressed a pilot arc is initiated within the torch which then transfers to the workpiece. The combination of the

electrical arc and the fast flowing air generates a plasma (very hot gas) jet which cuts the workpiece.

MODEL NO: ...........................................PP25.V2 .......... PP25PLUS.V2

Duty Cycle .........................................20% @ 25A ...............20% @ 23A

.........................................................100% @ 12A ...............35% @ 15A

Air Flow ................................................ 100ltr/min ...........Integral Comp.

Air Pressure ...............................................5-6 bar ...........Integral Comp.

Supply Voltage ................................... 230V - 1ph ................ 230V - 1ph

Power Absorbed ......................................... 2.8kW ........................2.8kW

Insulation Class ..................................................H ................................H

Protection ......................................................IP23 ...........................IP23

Weight ......................................................... 6.2kg ....................... 12.5kg

MODEL NO: ...........................................PP25.V2 .......... PP25PLUS.V2

Cutting Current ............................................5-25A .........................5-23A

Max. Cutting Capacity (Carbon Steel).......... 8mm .......................... 6mm

Torch

:

Gas ........................................Dry compressed air ...Dry compressed air

Air Pressure ...............................................5.5 bar .......................2.5 bar

Cooling Flow Rate ................................ 100ltr/min .................... 30ltr/min

Striking System .......................................Contact ......................Contact

Cutting Current ............................................7-25A .........................7-25A

1. INTRODUCTION & SPECIFICATIONS

Blue

Neutral

Wire

Yellow & Green

Earth Wire

Cable

Restraint

Brown

Live

Wire

FUSE RATING

13 AMP

Original Language Version

PP25.V2, PP25PLUS.V2 Issue: 6 - 17/01/10