Insufficient penetration or excessive scoria

settlement.

Interruption of cutting arc.

The torch is cutting at tilt when you wish it to

be perpendicular.

Excessive wear of nozzle and electrode.

Too high a cutting speed.

Torch is too tilted.

Workpiece is too thick.

Electrode and nozzle are worn out.

Cutting speed too low.

Excessive distance between torch and workpiece.

Electrode is worn out.

Intervention of the protection system.

Torch position not correct.

Asymmetric wear of nozzle hole and/or wrong assembly

of torch parts.

Air pressure too low.

Contaminated air (humidity-oil).

Excessive pilot arc ignitions in the air.

Nozzle holder damaged.

PROBLEM

POSSIBLE CAUSE

REMEDY

8. TROUBLESHOOTING

9. RATING PLATE

10. ELECTROMAGNETIC COMPATIBILITY

Slow the cutting speed.

Adjust the torch tilt.

Confirm workpiece thickness and re-check technical data.

Replace electrode and nozzle.

Increase cutting speed.

Decrease the distance between torch and workpiece.

Replace electrode and nozzle.

Check warning lights and take appropriate action.

Re-align the torch.

Check assembly (see fig.7/8) and change nozzle if necessary.

Increase air pressure (see Section 5).

Check air supply system (see Sections 4, 5 & 7).

Do not casually turn the torch on and off.

Change the nozzle holder.

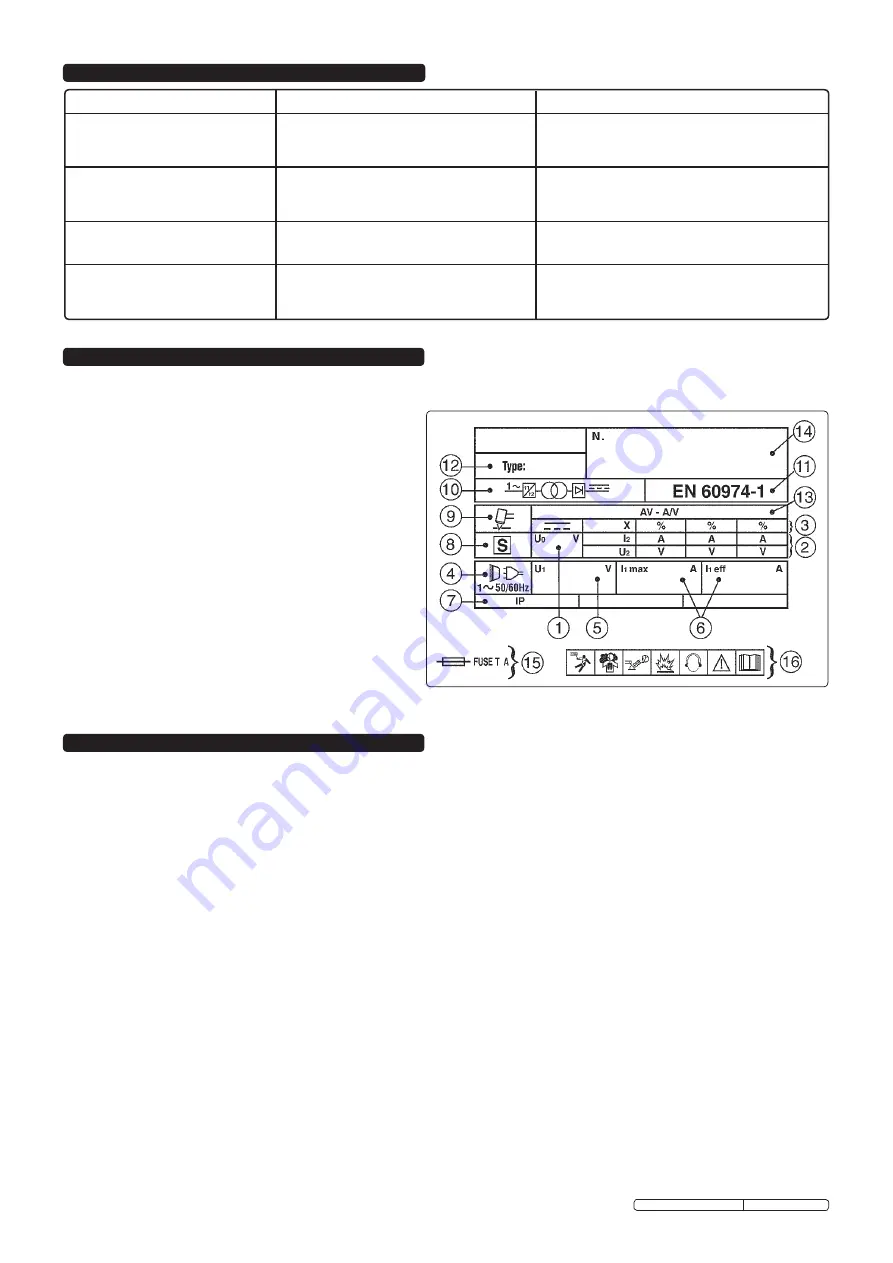

On the rear of the inverter is the rating plate, giving the following data:

1

- U

0

: Maximum open-circuit voltage.

2

- I

2

, U

2

: Current and corresponding voltage.

3

- X: Duty cycle, based on a 10 minute period. 30% indicates

3 minutes cutting and 7 minutes rest, 100% indicates

continuous cutting.

4

- Power Supply: AC, number of phases and frequency.

5

- U

1

: Rated supply voltage.

6

- I

1max

: Maximum RMS current absorbed. I

1eff

: Nominal RMS

current absorbed.

7

- Rating of internal protection provided by casing.

8

- S:

Indicates that cutting may be carried out in environments

with a heightened risk of electric shock e.g. very close to

large metallic objects.

9

- Symbol for type of process.

10

- Inverter-transformer-rectifier.

11

- The standard relating to the safety and construction of

welding and cutting equipment.

12

- Equipment model number.

13

- A/V-A/V: Cutting current range and corresponding voltages.

14

- Serial Number. Specifically identifies each inverter.

15

- Rating of delayed action fuse for supply protection.

16

- Symbols referring to safety.

10.1. THIS EQUIPMENT IS IN CONFORMITY WITH THE EUROPEAN STANDARD ON THE ELECTROMAGNETIC COMPATIBILITY

OF ARC WELDING EQUIPMENT AND SIMILAR PROCESSES (e.g. ARC AND PLASMA CUTTING)

10.2.

Protection against interference. (E.M.C.)

The emission limits in this standard may not, however, provide full protection against

interference to radio and television reception when the equipment is used closer than 30m to the receiving antenna. In special cases,

when highly susceptible apparatus is being used in close proximity, additional mitigation measures may have to be employed in order

to reduce the electromagnetic emissions. At the same time there could occur some potential difficulties in having electromagnetic

compatibility in a non-industrial environment (e.g. in residential areas). Therefore it is most important that the equipment is used and

installed according to the following instructions.

10.3.

Installation and use.

The user is responsible for installing and using the equipment according to these instructions. If electromagnetic

disturbances are detected, then it shall be the responsibility of the user of the equipment to resolve the situation with the technical

assistance of the supplier. In some cases this remedial action may be as simple as earthing the circuit (see Note). In other cases it

could involve constructing an electromagnetic screen, enclosing the welding power source and the work, complete with associated input

filters. In all cases the electromagnetic disturbances shall be reduced to the point where they are no longer troublesome.

Note: The welding/cutting circuit may or may not be earthed for safety reasons. Changing the earthing arrangements should only be

authorised by a person who is competent to assess whether the changes will increase the risk of injury, e.g. by allowing parallel

welding/cutting circuit return paths which may damage the earth circuits of other equipment. Further guidance is given in IEC 974-13

’Arc Welding Equipment - Installation and Use.’

10.4.

Assessment of area.

Before installing the equipment the user shall make an assessment of potential electromechanical problems in

the surrounding area. The size of the surrounding area to be considered will depend on the structure of the building and other activities

that are taking place. The surrounding area may extend beyond the boundaries of the premises.

The following shall be taken into account :

a) Other supply cables, control cables, signalling and telephone cables, above, below and adjacent to the welding equipment.

b) Radio and television transmitters and receivers.

c) Computer and other control equipment.

d) Safety critical equipment, e.g. security monitoring of industrial equipment.

e) The health of people in the vicinity, e.g. persons fitted with a pacemaker or hearing aid.

f) Equipment used for calibration or measurement.

g) The immunity of other equipment in the environment. The user shall ensure that other equipment being used in the environment is

compatible. This may require additional protective measures.

h) The time of day that welding and other activities are to be carried out.

Original Language Version

PP25.V2, PP25PLUS.V2 Issue: 6 - 17/01/10