WARNING: Use a welding head shield to protect your eyes and avoid exposing skin to the ultraviolet rays given off by the electric

arc.

Always wear protective clothing, insulating gloves and shoes. Keep all protective items clean and undamaged.

9

Remove ill fitting clothing before wearing protective clothing. Also remove watches, rings and other loose jewellery and contain long

hair.

9

Stand correctly, keeping a good footing and balance and ensure that the floor is not slippery. Wear non-slip shoes.

9

ensure that the workpiece is correctly secured before cutting.

9

Avoid unintentional contact with the workpiece. Accidental or uncontrolled switching on of the torch may be dangerous and will wear

the nozzle.

9

Keep unauthorised persons away from the work area. Any persons working within the area must wear the same protective items as

the operator.

8

Do not

use cables and torch if the insulation is worn or connections are loose.

8

Do not

attempt to fit any unauthorised torch or other component to the plasma cutting unit.

8

Do not

cut surfaces that are painted, galvanic coated, oily or greasy. These surfaces must be cleaned first. Wear a respirator suitable

for protection against toxic fumes, smoke and gases.

8

Do not

use cables over 10m in length.

8

Do not

connect the return cable to any structure which is not part of the workpiece (other than a metal work bench supporting the

workpiece).

▲

DanGer! Do not

cut near flammable materials - solids, liquids, or gases. Remove all flammable materials such as waste rags etc.

8

Do not

cut containers or pipes which have held flammable materials - gases, liquids or solids.

Do not

cut materials that have

been cleaned with chlorinated solvents (or near such solvents) as vapours from the arc action may produce toxic gases.

8

Do not

operate the inverter while under the influence of drugs, alcohol or intoxicating medication, or if tired.

8

Do not

use the plasma inverter for a task it is not designed to perform.

8

Do not

operate the plasma inverter if any parts are damaged or missing as this may cause failure and/or personal injury.

8

Do not

carry, or pull, the inverter by the leads or cables.

Do not

strain or bend the cables, protect them from sharp or abrasive

items and

Do not

stand on them.

9

Protect cables from heat. long lengths of slack must be gathered and neatly coiled.

Do not

place cables where they will endanger

others.

8

Do not

hold unsecured workpiece in your hand.

8

Do not

get the plasma inverter wet or use in damp or wet locations or areas where there is condensation.

8

Do not

touch the workpiece close to the cut as it will be very hot. Allow to cool. The cut edge of the workpiece will also be very

sharp.

8

Do not

touch the torch immediately after use. Allow the torch to cool.

9

When not in use store the unit in a safe, dry, childproof area.

2. introDUction

F

eatures an integral compressor yet weighs only 17kg. Inverter power supply fitted with plasma cutter control circuitry. With built in 4mtr plasma

torch, earth cable and 4mtr gas hose. Features LED display to show the current output and dial adjustment from 15-40Amp. Three indication

lights show voltage input, amps output and thermal overload. Uses air to strike arc making it suitable for use near electrical equipment. Ideal for

cutting steel, stainless, galvanised steel, aluminium, copper and brass. IP21S rated. 230V supply.

3. speciFication

model no: ............................................................. PP40PlUS

Power output: .............................................................

15-40A

duty Cycle: ...................... 20%@40A, 30%@35A, 60%@25A

maximum Cutting Thickness: ....................................... 10mm

Absorbed power: ..........................................................6.9kW

Supply: ...........................................................................230V

Insulation:.............................................................................F

Protection: .................................................................... IP21S

Weight: ........................................................................ 18.5kg

Replacement Consumables:

electrode Short (pack Qty.): ....................... PP40PlUS.e (5)

nozzle, Short (pack Qty.): ........................... PP40PlUS.n (5)

diffuser (pack Qty.): .................................... PP40PlUS.d (5)

Safety cap (pack Qty.): .............................PP40PlUS.SC (2)

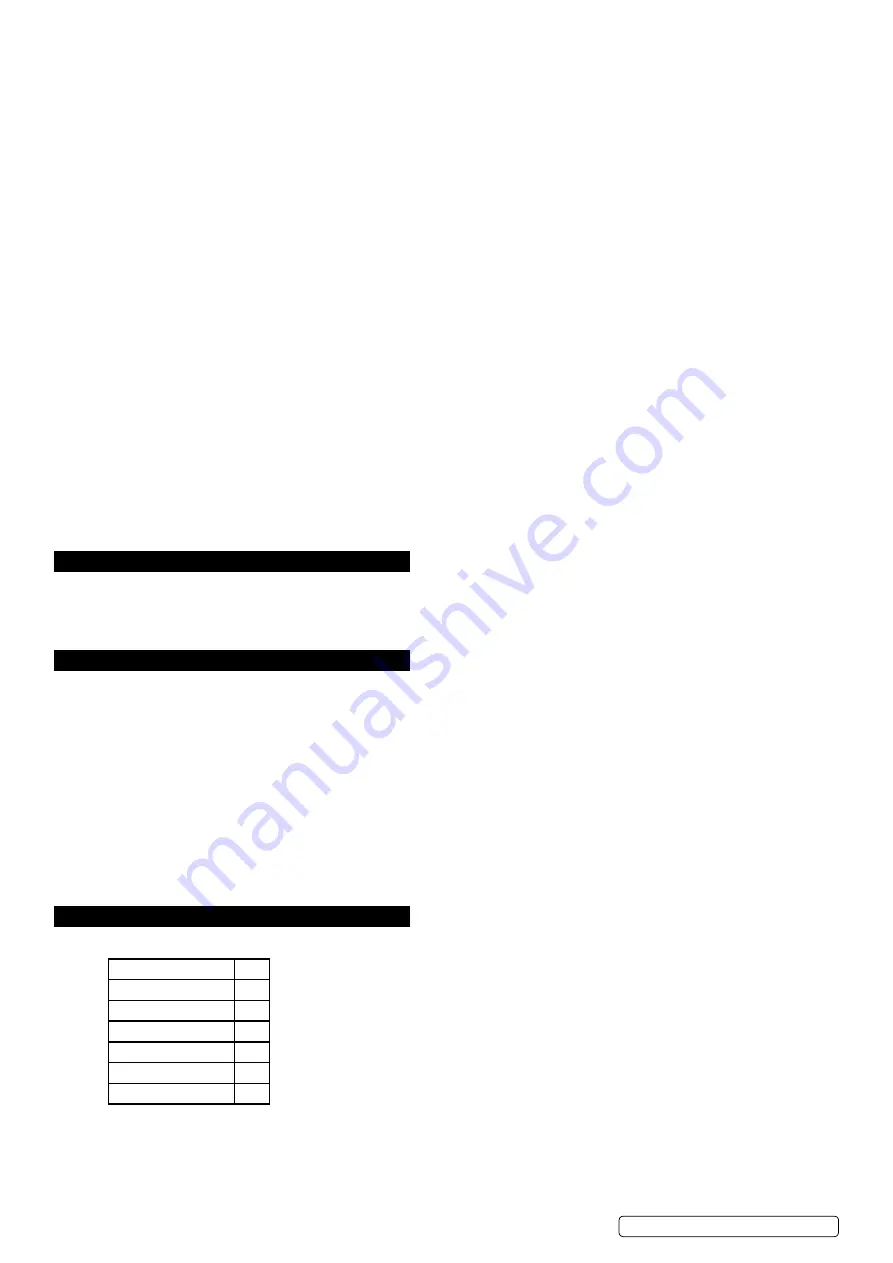

4. contents

4.1.

Remove contents from carton and check against contents list below.

Original Language Version

© Jack Sealey limited

item

qty.

Plasma cutter

1

Grounding cable

1

Cutting torch

1

electrode

3

Tip

3

Instruction manual

1

PP40PlUS | Issue:1 29/08/18