Important: Only fully qualified personnel should attempt maintenance or repair.

6.1

Monthly Maintenance

lubrication is critical to jacks, since they support heavy loads. Any restriction due to dirt or rust can cause either slow jack movement,

or extremely rapid jerks, causing damage to the internal components. To keep the jack well lubricated, carry out the following steps.

6.1.1 lubricate the ram, the linkages and the saddle and pump mechanism with light oil.

6.1.2

Grease the wheel bearing and axles.

6.1.3

Keep all jack surfaces and warning labels clean.

6.1.4 check and maintain the ram oil level (section 6.3).

6.2

Three Monthly Maintenance

6.2.1

At three monthly intervals, check the ram for any signs of rust or corrosion. clean the ram as required and wipe with an oil cloth.

6.3

Checking the Oil Level

6.3.1

Fully retract the ram by turning the release valve counterclockwise.

6.3.2

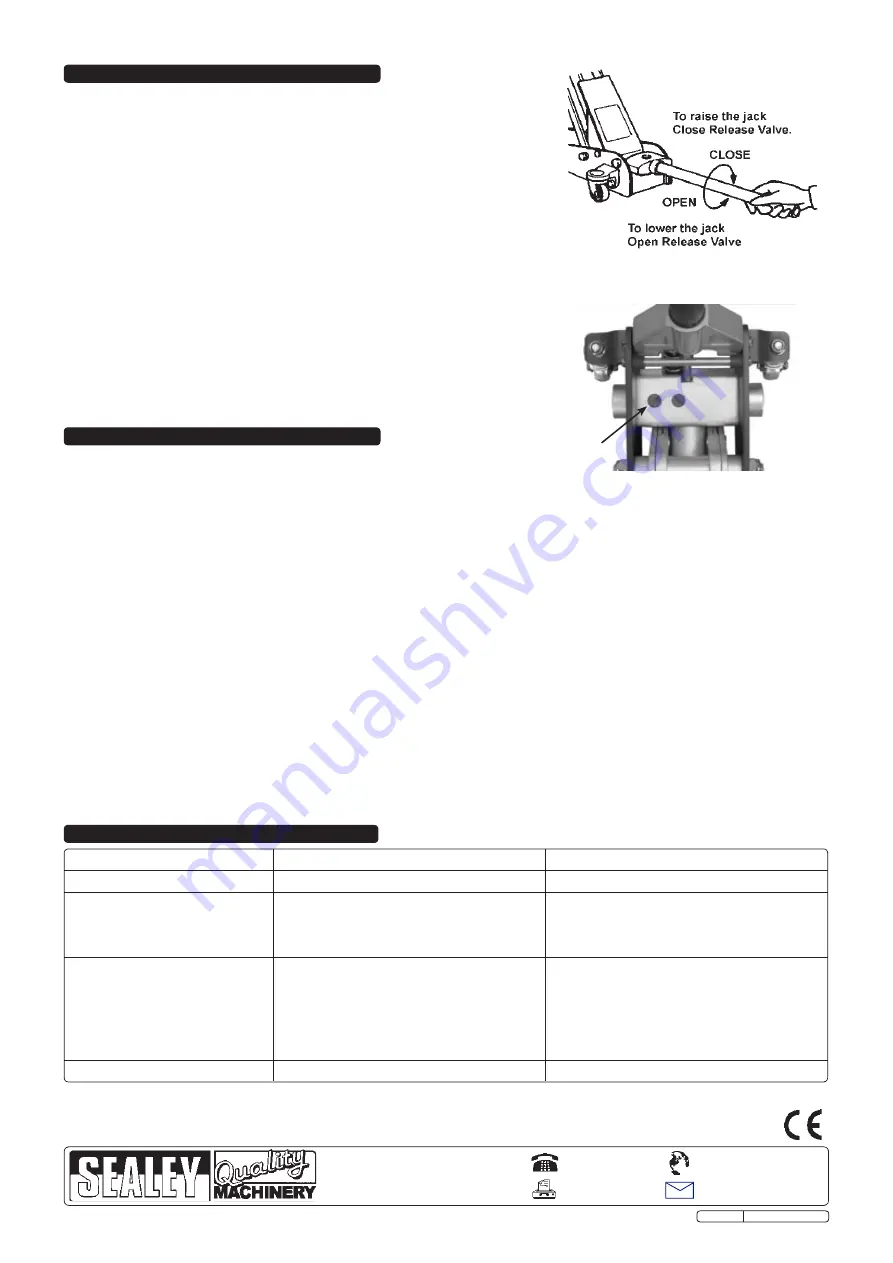

With the jack in the level position, remove the oil filler plug (Fig.4.A).

6.3.3

The oil should be level with the bottom of the oil filler hole. If it is not top up with clean hydraulic jack oil.

6.3.4 replace the oil filler plug and check the jack operation.

6.3.5

Purge air from the jacking system as required. refer to section 4.

nOTE:

Always store the jack in the fully lowered position. This will protect critical areas from excessive corrosion.

Important: no rESponSIBILItY IS aCCEptED For InCorrECt USE oF tHIS proDUCt.

Hydraulic products are only repaired by local service agents. We have service/repair agents in all parts of the UK.

Do not rEtUrn jaCkS to US.

Please telephone us on 01284 757500 to obtain the address and phone number of your local agent. If jack is under guarantee you can also

contact your local dealer.

6. MAInTEnAnCE

WARnInG! Before use ensure you have read, understood and apply Section 1

safety instructions.

IMPORTAnT:

Before use, the operator is to visually inspect the jack for cracked

welds, damaged or missing parts or hydraulic leaks.

5.1

Raising a vehicle

5.1.1

Ensure that the jack and the vehicle are on a hard, level surface.

5.1.2

Always ensure that the vehicle handbrake is engaged and that the vehicle wheels

are chocked.

5.1.3 consult the vehicle manual to determine the location of jacking points. Position the

jack under a suitable lifting point.

5.1.4

Turn the release valve clockwise, to the closed position (Fig.3).

dO nOT

over

tighten.

5.1.5 raise the vehicle to the designed height by pumping the handle up and down.

5.1.6

Place axle stands beneath the locations recommended by the vehicle

manufacturer.

5.1.7

Turn the release valve slowly counterclockwise to lower the vehicle on to the axle

stands.

5.2

Lowering a vehicle

5.2.1

Turn the release valve clockwise to the closed position.

5.2.2

Pump the handle to raise the vehicle off the axle stands.

5.2.3 remove the axle stands from beneath the vehicle.

5.2.4

Turn the release valve slowly counterclockwise to lower the vehicle to the ground.

nOTE: When not in use, ALWAYS leave the saddle and ram fully retracted.

5. OPERATInG InSTRUCTIOnS

de-commissioning the Jack

should the jack become completely unserviceable and require disposal, draw off the oil into an approved container and dispose of the jack

and the oil according to local regulations.

Fig.3

Fig.4

A

7. TROUBLESHOOTInG

PROBLEM

CAUSE

REMEdY

Jack will not lift to full height

oil level low

check / top up oil level.

Jack will not hold the load

release valve not closing

call for customer service

Hydraulic jack oil is contaminated

Pump valves not sealing

lift arm will not lower

cylinder ram binding

call for customer service

Parts worn

Internal component damage

Broken or unhooked return spring

lift arm linkage either bent or binding

Jack feels spongy when lifting

system requires purging

refer to air purge procedure at section 3

notE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTAnT:

no liability is accepted for incorrect use of this product.

WARRAnTY:

Guarantee is 12 months from purchase date, proof of which will be required for any claim.

InFORMATIOn:

For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

01284 757500

01284 703534

sales@sealey.co.uk

Sole UK distributor, Sealey Group,

Kempson Way, suffolk Business Park

,

Bury st. Edmunds, suffolk,

IP32 7Ar

www.sealey.co.uk

Web

Original Language Version

rJA1250 Issue: 2 - 04/11/09