4. OPERATION

2. INTRODUCTION & SPECIFICATIONS

Aluminium cylinders with cast iron liners give reduced weight and improved resistance to wear. Suitable for general-purpose workshop

applications. Pump head directly coupled to heavy-duty induction motor for reliable operation. Precision welded receiver tank manufactured to

meet Pressure Vessel Directive 87/404/EEC. Fitted with fully automatic pressure cut-out switch, air regulator and tank and supply pressure

gauges. Supplied with handle and wheels for easy manoeuvrability. Fitted with ASTA/BS approved non-rewirable plug.

3. PREPARATION

3.1.

Remove compressor from packaging and inspect for any shortages or damage. If anything is found to be missing or damaged contact

your supplier.

3.2.

Save the packing material for future transportation of the compressor. We recommend that you store the packing in a safe location, at

least for the period of the guarantee. Then, if necessary, it will be easier to send the compressor to the service centre.

3.3.

Confirm that the mains voltage corresponds with the voltage shown on the compressor data plate.

3.4

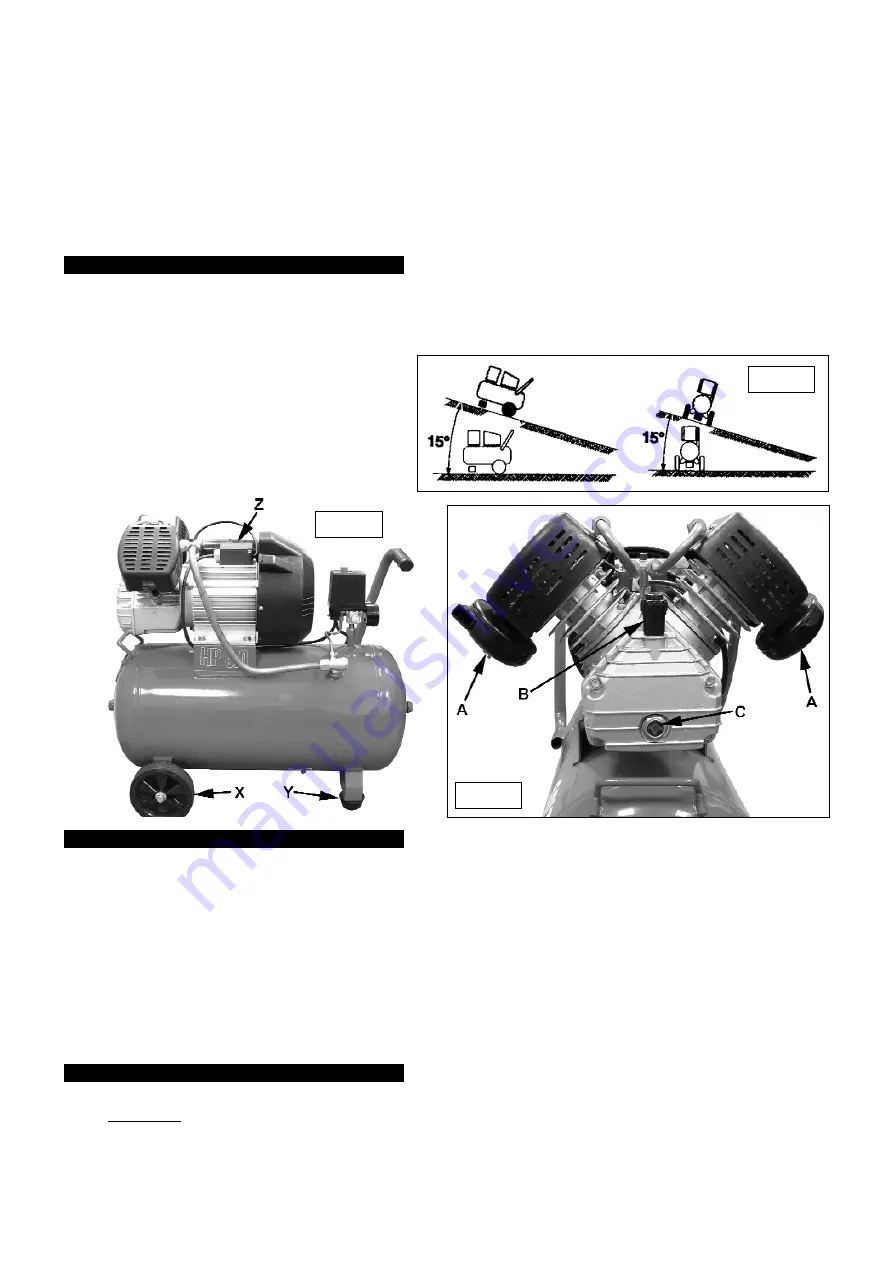

Assemble the wheels (fig.A-X) and rubber feet (fig.A-Y) to the main frame using using the nuts, bolts and washers supplied.

3.5.

The compressor should be operated on a flat surface, or one that does not exceed 15

O

either transversely or longitudinally (fig.1), and

should be in a position that allows good air circulation around the unit.

p

WARNING!

The compressor is shipped without oil in the pump. Do not start the compressor until it has been filled with oil (see below).

3.6.

Remove the plastic transit plug from the oil filler hole and pour in the recommended oil. (See section 5.7).

3.7.

Before using the compressor check the oil level by refering to the oil sight glass (fig.2-C). If the oil level is not up to the red centre

mark it should be further topped up. Screw the filler/breather cap into the aperture as shown in fig.2B.

3.8

Screw the back half of a filter unit into the downward facing port openings in each head as shown in fig.2-A. Place a filter cover over

each threaded rod protruding from the back half of the filter and secure each with a wing nut. Refer also to fig.4.

2.1.

Specification

DO NOT cover the compressor or restrict air flow around the machine whilst operating.

s

s

DANGER! DO NOT direct the output jet of air towards people or animals.

DO NOT

operate the compressor without an air filter.

DO NOT

allow anyone to operate the compressor unless they have received full instructions.

p

WARNING!

The air tank is a pressure vessel and the following safety measures apply:

DO NOT tamper with the safety valve and DO NOT modify or alter the tank in any way and DO NOT strap anything to the tank.

DO NOT subject the tank to impact, vibration or to heat and DO NOT allow contact with abrasives or corrosives.

DO drain condensation from tank daily and inspect inside walls for corrosion every three months and have a detailed tank inspection

carried out annually.

The tank shell must not fall below the certified thickness at any point.

p

p

WARNING!

If an electrical fuse blows, ensure it is replaced with an identical fuse type and rating.

When not in use, store the compressor carefully in a safe, dry, childproof location.

Model No . . . . . . . . . . . . . . . . SA22503

Motor Output. . . . . . . . . . . . . . 3.0hp

Voltage/Phase . . . . . . . . . . . . . 230V - 1ph

Input Current. . . . . . . . . . . . . . 9.3A

Piston Displacement . . . . . . . . 12.6cfm

Max Free Air Delivery . . . . . . . 9.2cfm

Tank Capacity . . . . . . . . . . . . . 50ltr

Max. Pressure. . . . . . . . . . . . . 116psi/8bar

fig. 2

fig. 1

p

p

WARNING! Ensure that you have read, understood and apply Section 1 safety instructions.

4.1.

IMPORTANT. The use of extension leads to connect this compressor to the mains is not recommended as the resulting

voltage drop reduces motor, and therefore pump, performance.

4.2.

Take care when selecting tools for use with the compressor. Air tool manufacturers normally express the volume of air

required to operate a tool in cubic feet per minute (cfm). This refers to free air delivered by the compressor (air out) which

varies according to the pressure setting. Do not confuse this with the compressor displacement which is the air taken in by

the compressor (air in). Air out is always less than air in - due to losses within the compressor .

SA22503 - 1 - 17/05/05

fig. A