NOTE:

It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

iMPOrtANt:

no liability is accepted for incorrect use of this equipment

WArrANtY:

Guarantee is 12 months from purchase date, proof of which will be required for any claim.

iNFOrMAtiON:

for a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

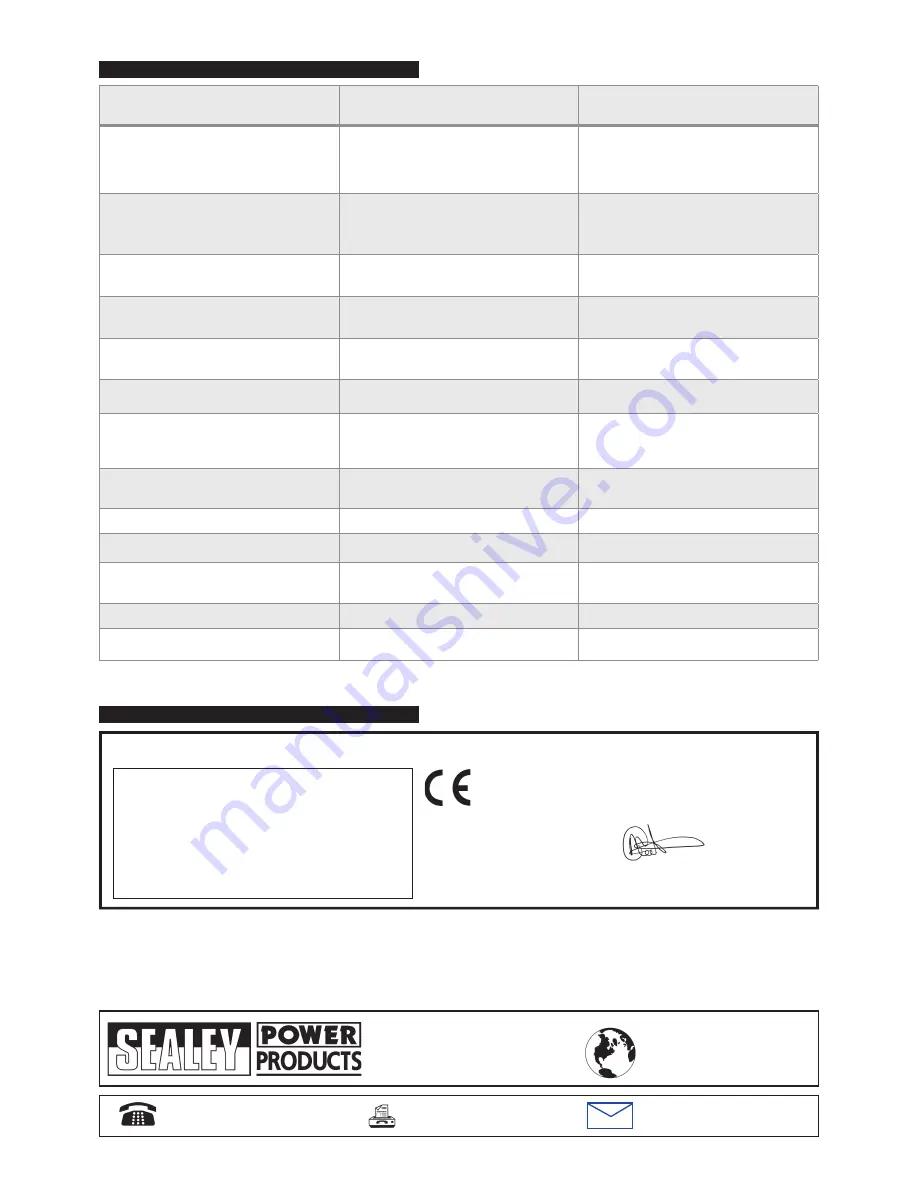

Declaration of Conformity

We, the sole uK importer, declare that the product listed below is in conformity with the following

standards and directives.

the construction file for this product is held by the manufacturer

and may be inspected, by a national authority, upon request

to Jack sealey ltd.

For Jack Sealey Ltd. Sole UK importer of Sealey Power Products.

six litre COMPressOr

Model: sA2306

2006/42/ec machinery directive

87/404/eec Pressure Vessel directive

2004/108/ec emc directive

2006/95/ec low Voltage directive

signed by mark sweetman

11th July 2003

6. trOUBlesHOOtiNG

7. DeClArAtiON OF CONFOrMitY

www.sealey.co.uk

01284 757500

01284 703534

sales@sealey.co.uk

sole UK Distributor

sealey Group,

Bury st. edmunds, suffolk.

Web

FAUlt

CAUse

reMeDY

1a) Pressure drop in the tank

air leaks at connections

run compressor to max. pressure, switch off.

Brush soap solution over connections and look for

bubbles. tighten connections showing leaks.

If problem persists contact authorised service agent.

1B)

Pressure drop in the tank

air leaks from safety valve

operate the safety valve manually by pulling on the

ring. If valve continues to leak when in the closed

position it should be replaced

1c) Pressure drop in the tank

air leaks from cylinder head gasket

check tightness of head bolts. If leak continues

contact authorised service agent.

2) Pressure switch valve leaks when

compressor is idle

non-return valve seal defective

empty the air tank, remove the non-return valve

cap and clean, or if necessary replace the seal.

3) air leaks from tank body or tank welds

Internal corrosion caused by infrequent tank

draining or non permitted modifications to tank

tank could rupture or explode. cannot be repaired.

DisCONtiNUe Use iMMeDiAtelY

4a) motor stops and will not restart

thermal cut out has operated

allow unit to cool for 30 minutes before restarting

4B) motor stops and will not restart

supply fuse has tripped

reset fuse and restart unit. If repeated tripping

occurs replace the check valve or contact

authorised service agent

4c) motor stops and will not restart

current overload trip has operated

Investigate and remedy reason for overload.

reset by pushing button back in (see fig.3d)

5) compressor stops and does not restart

motor failure

contact authorised service agent.

6a) compressor does not stop at max. pressure

Pressure switch fault

contact authorised service agent.

6B) compressor does not stop at max. pressure

filter clogged

head gasket or valve fault

replace filter element.

contact authorised service agent.

7) compressor noisy with metallic knock

Bearing or piston damage

contact authorised service agent.

8) excessive moisture in discharged air

high humidity environment

drain tank after each use

sa2306 - 2 - 010208