2.

INTRODUCTION & SPECIFICATIONS

3.1. Air Supply

3.1.1. Ensure the sander air valve (or throttle) is in the "off" position before connecting to the air supply.

3.1.2. You will require an air pressure between 70-90psi, and an air flow according to the specification above.

3.1.3.

p

WARNING!

Ensure the air supply is clean and does not exceed 90 psi while operating the sander.

Too high an air pressure and unclean air will shorten the product life due to excessive wear, and may be

dangerous causing damage and/or personal injury.

3.1.4. Drain the air tank daily. Water in the air line will damage the sander

and will invalidate your warranty.

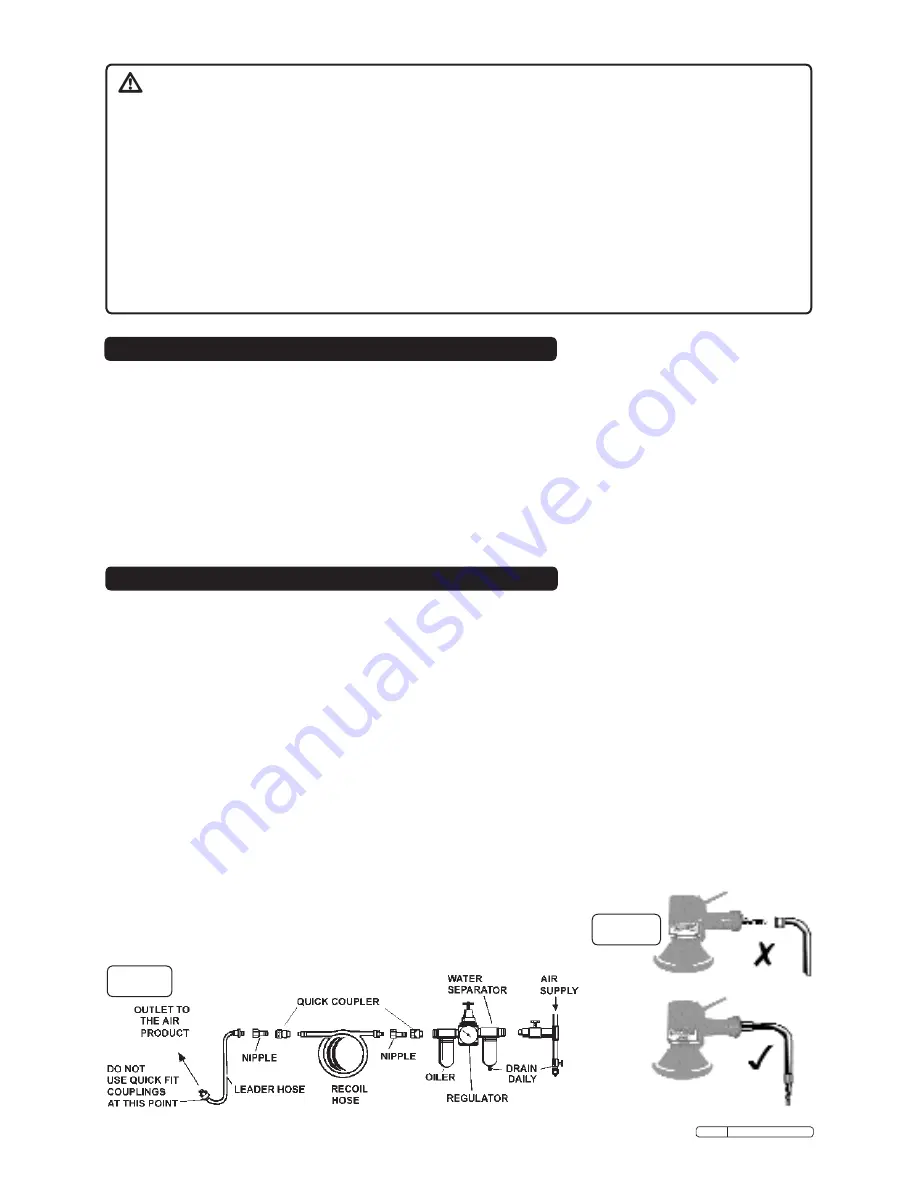

3.1.5. Clean air inlet filter weekly. Recommended hook-up procedure is shown in fig 1.

3.1.6. Line pressure should be increased to compensate for unusually long air hoses (over 8 metres).

The minimum hose diameter should be 1/4” I.D. and fittings must have the same inside dimensions.

3.1.7. Keep hose away from heat, oil and sharp edges. Check hoses for wear, and make certain that all

connections are secure.

3.2. Couplings.

Vibration may cause failure if a quick change coupling is connected directly to the air sander. To

overcome this, connect a leader hose to the sander. A quick change coupling may then be

used to connect the leader hose to the air line recoil hose. See fig 1 & 2.

3.

PREPARING SANDER FOR USE

1.2. LEAD PAINT WARNING!

Paint once contained lead as a traditional ingredient. Contact with the dust from the removal of such

paint is toxic and must therefore be avoided. The following action must be taken before using the

sander on a surface that you suspect may contain lead paint.

1.

User must determine potential hazard relating to age of paint to be removed.

(Modern paints do not have lead content).

2.

DANGER!

Keep all persons and pets away from the working area. The following persons are

particularly vulnerable to the effects of lead paint dust:

Expectant women, babies and children.

3.

We recommend personal protection by using the following safety items:

a

) Paint Spray Respirator (Our ref SSP16EN)

b

) PE Coated Hooded Coverall (Our ref SSP266).

c

) Latex Gloves (Our ref SSP24).

4.

Take adequate measures to contain the paint dust, flakes and scrapings.

5.

Continue to wear safety equipment as in (3) above and thoroughly clean all areas when task is

complete. Ensure paint waste is disposed of in sealed bags or containers.

fig 1

Pad sizes . . . . . . . . . . . . . . . . . 150mm

Thread size. . . . . . . . . . . . . . 5/16” UNF

Free Speed . . . . . . . . . . . . . 10000rpm

Operating Pressure . . . . . . . . . . . 90psi

Air Consumption . . . . . . . . . . . . . .4cfm

Air Inlet . . . . . . . . . . . . . . . . . . 1/4BSP

Weight . . . . . . . . . . . . . . . . . . . . . . .2kg

Sound . . . . . . . . . . . . . . . . . . 93.3bB(A)

. . . . . . . . . . . . . . . . . . . . . . . 92.8dB(C)

The SA7T has internally chromed cylinder and precision bearings for super-smooth operation. The sander is

fitted with an air-flow control valve and housing insulation to prevent hand-chill.

fig 2

Original Language Version

SA7T Issue: 2 - 28/10/09