4. PREPARATION

4.1.

AIR SuPPLY

WARNING!

Ensure the air supply is clean and does not exceed 90psi while operating the tool. Too high an air pressure and unclean

air will shorten the product life due to excessive wear and may be dangerous, causing damage and/or personal injury.

4.1.1.

Ensure the air valve (or trigger) is in the “off” position before connecting to the air supply.

4.1.2.

You will require an air pressure of 90psi, and an air flow according to specification.

4.1.3.

Drain the air tank daily. Water in the air line will damage the tool

and will invalidate your warranty.

Clean air inlet filter weekly.

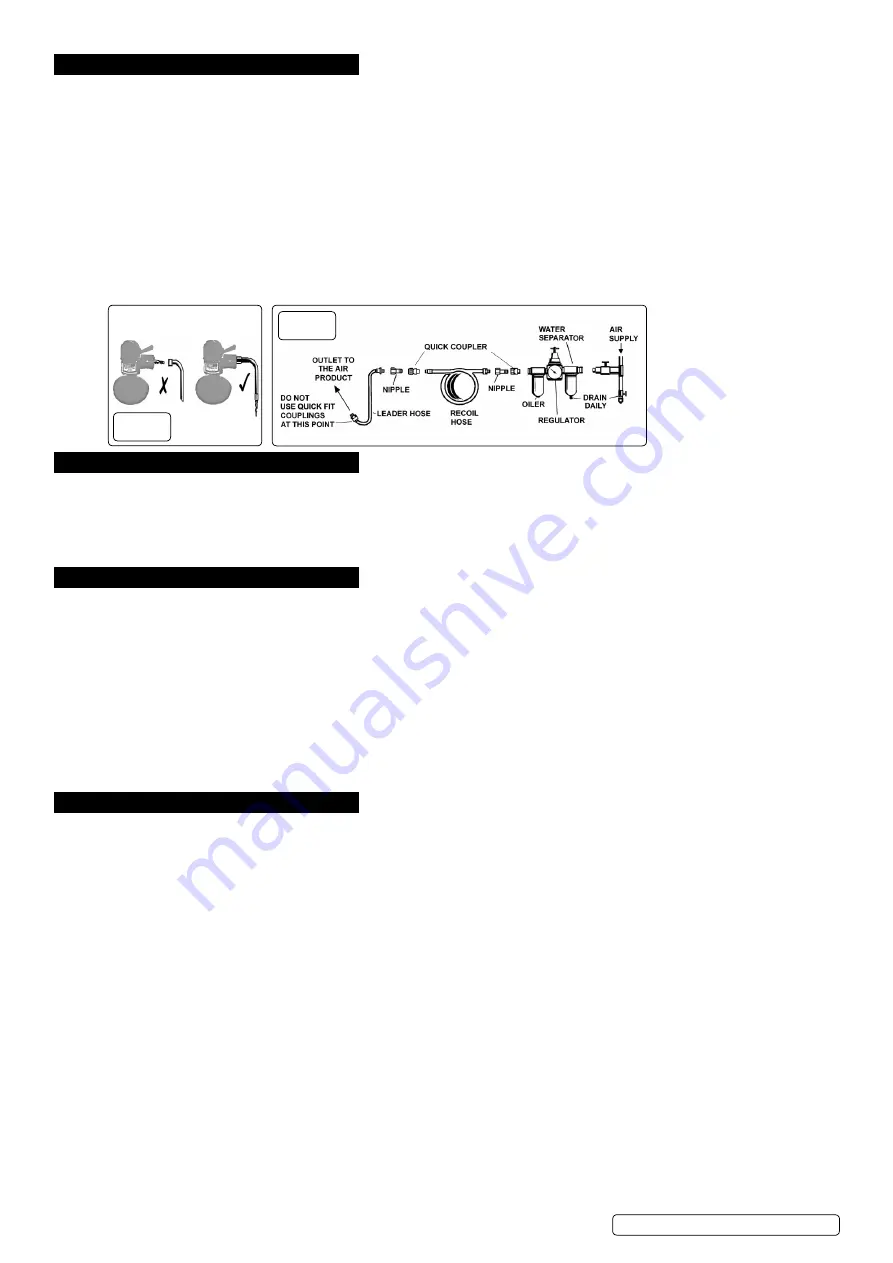

Recommended hook-up procedure is shown in fig.2.

4.1.4.

Line pressure should be increased to compensate for unusually long air hoses (over 8metres).

4.1.5.

The minimum hose diameter should be 1/4” internal diameter and fittings must have compatible dimensions.

4.1.6.

Keep hose away from heat, oil and sharp edges. Check hoses for wear, and make certain that all connections are secure.

4.2.

cOuPLINGS

4.3.

Vibration may cause failure if a quick change coupling is connected directly to the tool. To overcome this, connect a leader hose to the

tool (Sealey ref: AH2R or AH2R/38). A quick change coupling may then be used to connect the leader hose to the air line recoil hose.

See fig.1 & fig.2.

5. ASSEMBLY

WARNING!

Ensure you read, understand and apply Section 1 safety instructions.

5.1.

Screw composite pad fully onto shaft of removing tool. Use only pads with speed ratings equal to or higher than the speed rating of the

tool. A spanner is provided to hold the shaft during pad removal.

5.2.

Connect air supply to tool and press control valve lever (push safety catch forward) to check for correct operation.

5.3.

The air flow may be regulated by the control valve lever.

6. OPERATION

6.1.

DO NOT

apply excessive pressure, let the tool do the work. Start the tool and bring the edge of the pad to the work surface smoothly

and slowly. move the tool back and forth in overlapping areas to remove the stripe. Lift the pad from the work surface before stopping

the tool. Regularly check the pad for wear - note minimum diameter marking - and always change a damaged pad.

8

DO NOT

allow tool to run in “idle rotation” for an extended period of time as this will damage the bearings.

6.1.1.

A new pad should be run on a hidden or scrap panel to buff the surface before being used for pinstripe removal.

6.1.2.

Before starting each job run the pad on a patch of hidden paintwork to check that no damage is caused.

6.1.3.

When used on two pack paints the surface finish may be slightly marked or hazy. Use a high grade cutting compound to restore the

surface finish.

6.1.4.

When used on cellulose paints, greater care and time are required to ensure that the minimum of heat is generated. If this care is not

taken, heat will damage the surface finish.

6.1.5.

The tool will also remove the double sided tape used to attach body trim. This process is slower than stripe removal and may produce

an unpleasant odour.

7. MAINTENANcE

WARNING!

Disconnect air supply before changing accessories, servicing or performing maintenance. Replace or repair damaged parts.

Use genuine parts only. Non-authorised parts may be dangerous and will invalidate the warranty.

7.1.1.

If there is no oiler in the air supply system, lubricate the tool daily with a few drops of good grade air tool oil such as Sealey ATO/500 or

ATO1000, dripped into the air inlet before use.

7.1.2.

Clean the sander after use and change pad when required.

7.1.3.

Loss of power or erratic action may be due to the following:

a)

Excessive drain on the air system. moisture or restriction in the air line. Incorrect size or type of hose

connectors. To remedy check the air supply and follow instructions in Section 3.

b)

Grit or gum deposits in the tool may also reduce performance. If your model has an air strainer

(located in the area of the air inlet), remove the strainer and clean it. Flush the tool out with gum

solvent oil or an equal mixture of SAE 10 oil and kerosene. Allow to dry before use.

7.1.

If you continue to experience problems, contact your local Sealey service agent.

7.2.

For a full service contact your local Sealey service agent.

7.3.

When not in use, disconnect from air supply, clean and store in a safe, dry, childproof location.

fig.1

fig.2

Original Language Version

© Jack Sealey Limited

SA95.V3 | Issue:2 (H,F) 19/12/18