01284 757500

01284 703534

E-mail:

sales@sealey.co.uk

NOTE:

It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT:

No liability is accepted for incorrect use of this equipment

WARRANTY:

Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION:

For a copy of our latest catalogue call us on 01284 757525 and leave your full name and address, including postcode.

Sole UK Distributor

Sealey Group,

Bury St. Edmunds, Suffolk.

Declaration of Conformity

We, the sole UK importer, declare that the products listed below

are

in conformity with the following

standards and directives.

The construction files for th

ese

products

are

held by the

Manufacturer and may be inspected on request by contacting

Jack Sealey Ltd.

For Jack Sealey Ltd. Sole UK importer of Sealey

Power Products.

DIRECT DRIVE COMPRESSORS

Models: SA9925/1.5, SA9925/2 &

SA9950/2

87/404/EEC Pressure Vessel Directive

89/336/EEC EMC Directive

73/23/EEC LV Directive

98/37/EC Machinery Directive

Signed by Mark Sweetman

1st September 1999

SA9925/1.5 & /2 & SA9950/2 - 1069 - (2) - 280600

b) Check all tube fittings and electrical connections.

c) Inspect pressure tank inside and out for damage or corrosion.

5.6.

Scheduled maintenance table

5.7.

Recommended oils

Recommended oil for compressors, suitable for room

temperatures ranging from +5

O

C to +25

O

C.

SEALEY CPO or equivalent SAE 40 compressor oil.

Room temperature below +5

O

C: SAE 20 compressor oil.

Approximate oil capacity: 0.16 litres.

fig. 5

6. TROUBLE SHOOTING

Internal & external

inspection of tank

General cleaning of

compressor

Check tube fittings and

electrical connections

Check for oil leaks

Replace air filter

Clean intake filter

Check oil level

Drain condensation

500 hrs.

200 hrs.

100 hrs.

Daily

Maintenance

Operations

Replace oil

Check cut-out

Fault

Cause

Remedy

Pressure drop in the tank

Air leaks at connections

Run compressor to max. pressure, switch off.

Brush soap solution over connections and look for

bubbles. Tighten connections showing leaks.

If problem persists contact Authorised Service Agent.

Pressure switch valve leaks when compressor is idle

Non-return valve seal defective

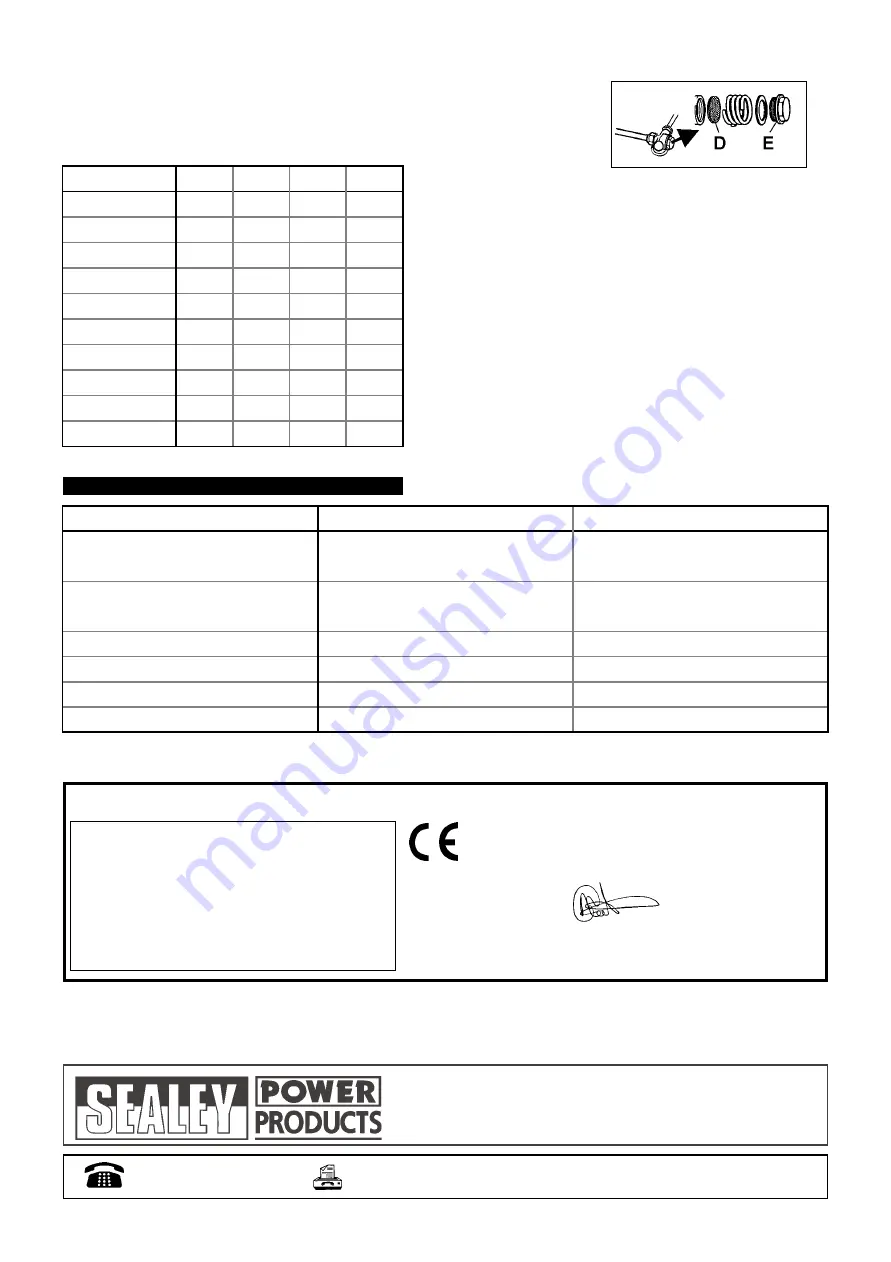

Empty the air tank, remove the non-return valve cap

E (fig.5) and clean, or if necessary replace,

the seal D.

Compressor stops and does not restart

Motor failure

Contact Authorised Service Agent.

Compressor does not stop at max. pressure

Pressure switch fault

Contact Authorised Service Agent.

Compressor does not stop at max. pressure

Filter clogged

Head gasket or valve fault

Replace filter element.

Contact Authorised Service Agent.

Compressor noisy with metallic knock

Bearing or piston damage

Contact Authorised Service Agent.