pRoBLeM

possIBLe cAuse

ReMedy

Jack will not lift

the load

Jack does not lift

high enough or

feels “spongy”

Jack lifts but will

not hold load

Jack will not lower

completely

1) Be sure to use jack with adequate capacity.

2) Top up oil level.

3) Check and close release valve.

4) Open release valve and air vent (if fitted) and pump the handle a few times. Close valve and re-try.

5) Return jack to local service agent.

1) Top up oil level.

2) Return jack to local service agent.

3) Open release valve and air vent (if fitted) and pump the handle a few times. Close valve and re-try.

4) Check and close release valve.

1) Check and close release valve.

2) Open release valve and air vent (if fitted) and pump the handle a few times. Close valve and re-try.

3) Return jack to local service agent.

1) Contact local service agent.

2) Open release valve and air vent (if fitted) and pump the handle a few times. Close valve and re-try.

3) Check and fully open release valve.

1) Overloaded

2) Oil level low

3) Release valve not correctly closed

4) Air in system

5) Packing worn or defective

1) Oil level low

2) Worn seals

3) Air in system

4) Release valve not closed

1) Release valve partially open

2) Air in system

3) Faulty seals

1) Ram damaged

2) Air in system

3) Release valve only partially open

3.2.6. Lower the vehicle onto suitable axle stands before attempting any work.

3.3. Lowering

3.3.1. Ensure that the axle stands are removed and that there are no persons or obstacles beneath the vehicle, or in the path of its descent.

3.3.2. The lowering speed is controlled by the amount the release valve (1) is opened. Turn valve anti-clockwise and lower slowly and carefully.

4. MAINteNANce

5. tRouBLeshootING

ImpoRtANt:

only fully qualified personnel should attempt maintenance or repair.

WARNING:

Do Not

use brake fluid, or any fluid other than Sealey hydraulic jack fluid, as to do so may cause serious damage to the

jack and will invalidate the warranty!

4.1. When the jack is not in use, the ram and piston must be in their lowest positions to minimise corrosion. Remove the handle to inactivate

jack.

4.2. Keep the jack clean and lubricate all moving parts with acid free oil on a regular basis.

4.3. To check oil level, fully lower the jack. Remove filler plug. The correct oil level is to the bottom of the filler opening.

4.4. After a year of extensive use, the oil should be replaced in order to extend the life of the jack. Drain the oil through the filler plug opening.

Make sure that no dirt is allowed to enter the jack or the fresh oil.

4.5. To replace the oil fill as required. Pump (unloaded jack) 5 or 6 times to expel air. Pump jack to full height and pour off excess oil before

refitting plug.

Note:

Ensure waste oil is disposed of in accordance with local authority regulations.

4.6. Before each use check for broken, cracked, bent, or loose parts. Also check for any visible damage to welds, ram, pump, body and base.

If any suspect item is found remove jack from service and take the necessary action to remedy the problem.

do Not

use the jack if believed to have been subjected to abnormal load or shock. Inspect and take appropriate action.

4.7. Periodically check the pump piston and piston rod for signs of corrosion. Clean exposed areas with a clean oiled cloth.

ImpoRtANt:

No RESpoNSIBILItY IS ACCEptED FoR INCoRRECt USE oF tHE JACK .

Hydraulic products are only repaired by local service agents. We have service/repair agents in all parts of the UK.

Do Not REtURN JACKS

to US.

Please telephone 01284 757500 to obtain address and ‘phone number of your local agent. If jack is under guarantee please contact

your dealer.

de-commissioning:

Draw off the oil into an approved container and dispose of the jack and the oil according to local regulations.

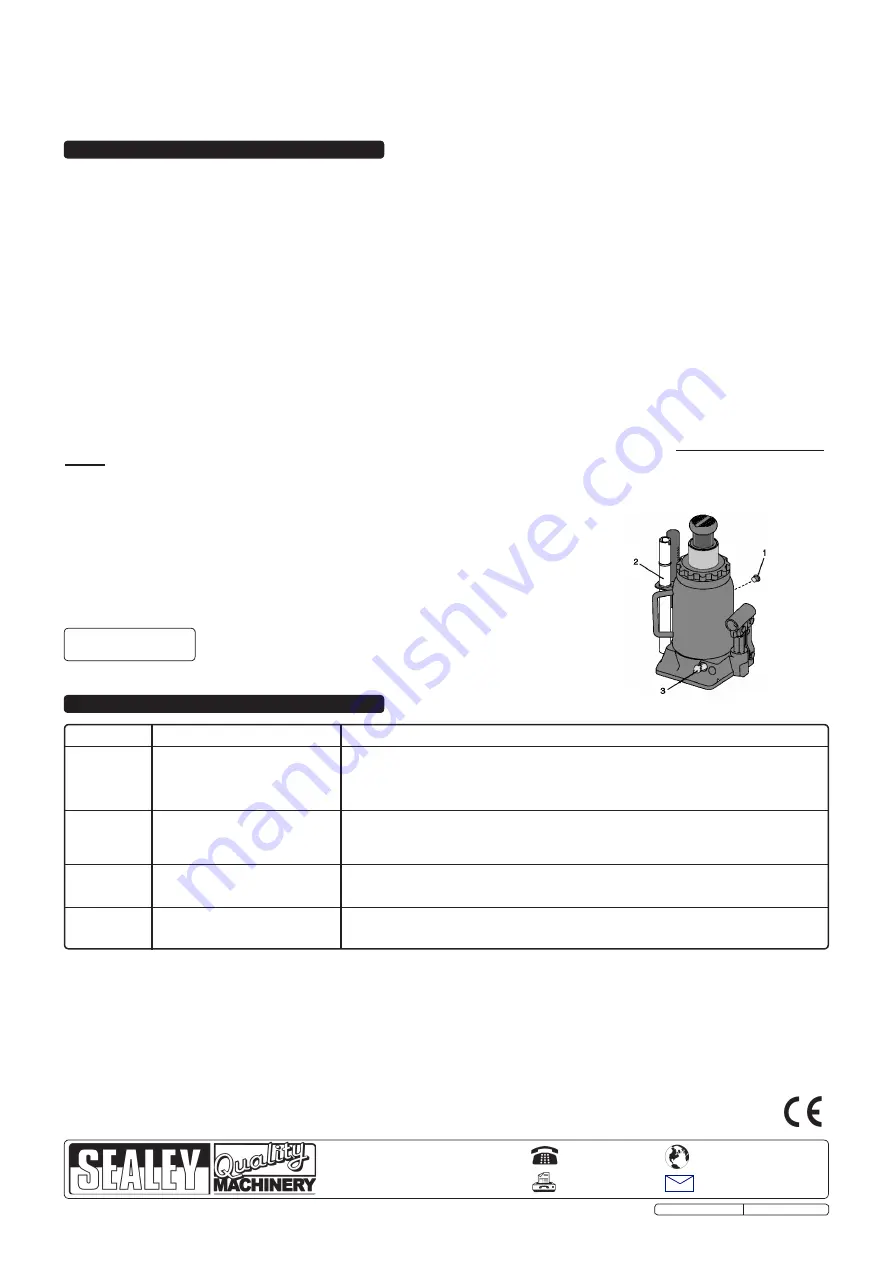

parts List: sBj12Q

Item

part No:

description

1

SBJ12Q.01. . . . . OIL FILLER PLUG

2

SBJ12Q.02. . . . . HANDLE ASSEMBLY

3

SBJ12Q.03. . . . . RELEASE VALVE

SBJ12Q.04. . . . . REPAIR KIT

parts List: sBj20Q

Item

part No:

description

1

SBJ20Q.01. . . . . OIL FILLER PLUG

2

SBJ20Q.02. . . . . HANDLE ASSEMBLY

3

SBJ20Q.03. . . . . RELEASE VALVE

SBJ20Q.04. . . . . REPAIR KIT

Parts Issue:

1

Issue Date:

040504

NotE:

It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMpoRtANt:

No liability is accepted for incorrect use of this product.

WARRANty:

Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INfoRMAtIoN:

For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

01284 757500

01284 703534

sales@sealey.co.uk

sole uk distributor, sealey Group,

Kempson Way, Suffolk Business Park

,

Bury St. Edmunds, Suffolk,

IP32 7AR

www.sealey.co.uk

Web

Original Language Version

SBJ12Q, SBJ20Q Issue: 2 - 01/04/10