5. AIR SUPPlY

5.1.

Air Supply

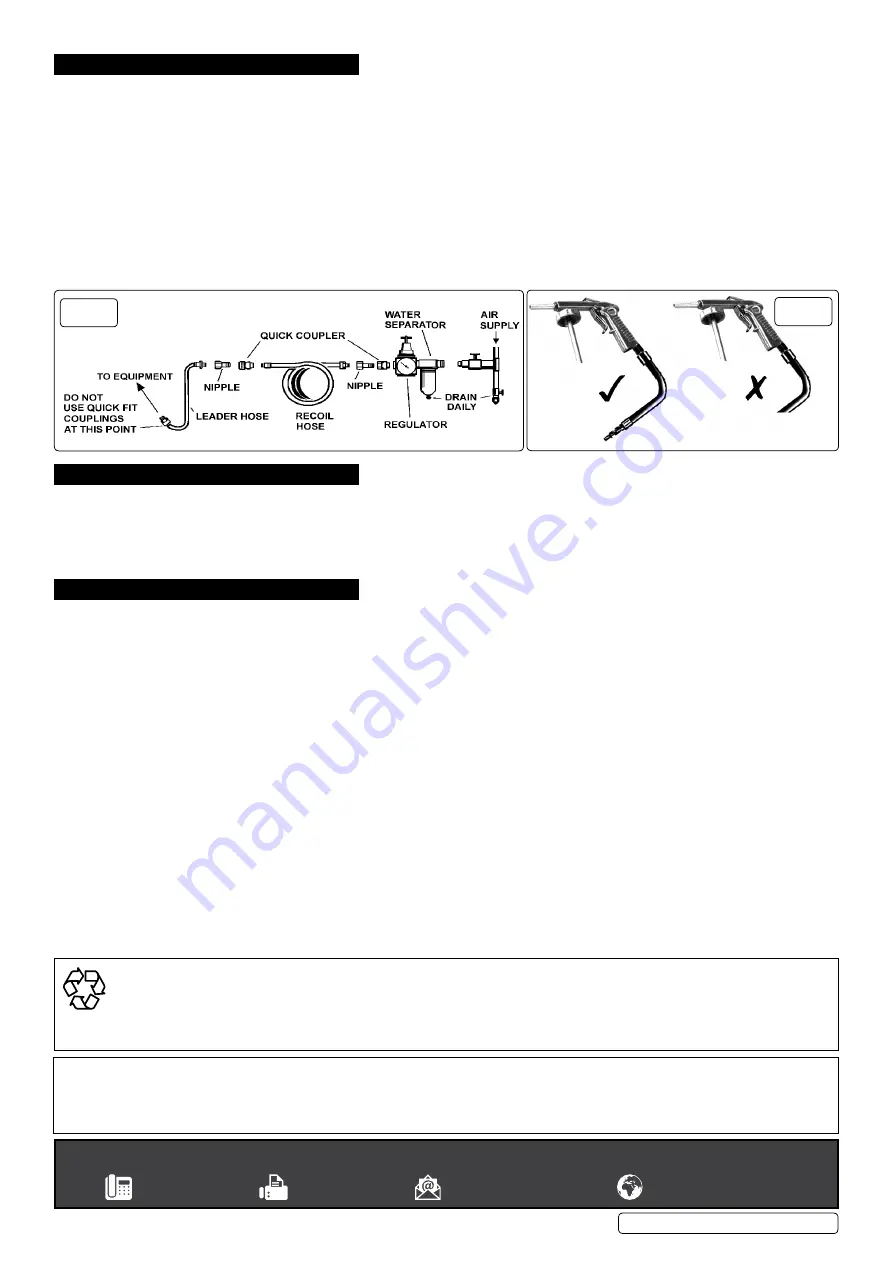

(Recommended hook-up procedure is shown in fig.1).

5.2.

ensure the gun air valve (trigger) is in the off position before connecting to the air supply.

WARNING!

ensure the air supply is clean and does not exceed 90psi while operating the spray gun. Too high an air pressure will

shorten the product life and may be dangerous causing damage or personal injury.

5.3.

drain the air supply tank daily. Water in the air line will ruin the paint finish and damage the spray gun.

5.4.

Clean air inlet filter weekly.

5.5.

line pressure should be increased to compensate for unusually long air hoses (over 8 metres). The minimum hose diameter should be

1/4” I.d. and fittings must have the same inside dimensions.

5.6.

Keep hose away from heat, oil and sharp edges. Check hose for wear, and make certain that all connections are secure.

5.7.

Couplings

5.7.1.

Vibration may cause failure if a quick change coupling is connected directly to the spray gun. To overcome this, connect a leader hose

to the spray gun. A quick change coupling may then be used to connect the leader hose to the air line recoil hose. See fig.1 & 2.

6. OPERATION

WARNING!

ensure you read, understand and apply the safety instructions in section 1and follow the manufacturer’s instructions on

the under body coating container.

6.1.

Screw on the canister of under body coating.

6.2.

ensure the air supply is regulated to no more than 6bar (90psi) than attach the leader hose to the gun.

6.3.

Test for correct operation in a safe area first.

7. MAINTENANCE

WARNING! Ensure the gun is disconnected from the air supply before attempting any internal maintenance.

7.1.

After use, remove the partially used or spent canister and reseal if required.

7.2.

Purge the gun into a safe area and then isolate the mains air before removing the leader hose.

7.3.

Clean all components of the gun thoroughly with paraffin, especially items (1,2,4 and 5) and allow to dry before storage.

DO NOT

connect direct to

an air line recoil hose.

leader Hose

quick release

Sealey Group, Kempson Way, Suffolk Business Park, Bury St Edmunds, Suffolk. IP32 7AR

01284 757500

01284 703534

sales@sealey.co.uk

www.sealey.co.uk

ENVIRONMENT PROTECTION

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken to

a recycling centre and disposed of in a manner which is compatible with the environment. When the product becomes completely

unserviceable and requires disposal, drain any fluids (if applicable) into approved containers and dispose of the product and fluids

according to local regulations.

Note

: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior

notice.

Important

: no liability is accepted for incorrect use of this product.

Warranty

: Guarantee is 12 months from purchase date, proof of which is required for any claim.

SG139.V2 |Issue:4 (H,F) 09/03/18

Original Language Version

© Jack Sealey limited

fig.1

fig.2