01284 757500

E-mail:

sales@sealey.co.uk

01284 703534

NOTE:

It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT:

No liability is accepted for incorrect use of this product.

WARRANTY:

Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION:

For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name, address and postcode.

Sole UK Distributor,

Sealey Group

, Bury St. Edmunds, Suffolk.

p

WARNING!

Ensure the grinder is disconnected from the mains power supply before attempting any maintenance.

6.1.

Cleaning

Keep the grinder ventilation slots clean and free from obstructions. If available, blow compressed air into the vents to clear any internal

dust (safety goggles must be warn when undertaking this process). Keep the outer case of the grinder clean and free from grease.

DO NOT wash with water or use solvents or abrasives.

6.2.

Brushes

Only an authorised Sealey service agent should change the brushes.

p

p

WARNING!

Ensure grinder is unplugged from the mains power supply before changing accessories.

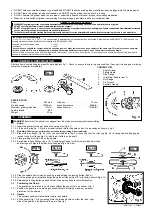

5.1.

Preparation

5.1.1. Assemble grinding disc according to 3.2. and position the auxiliary handle to suit the task.

5.1.2. Ensure the disc safety guard is correctly positioned.

5.1.3. Plug grinder into the mains power supply.

5.2.

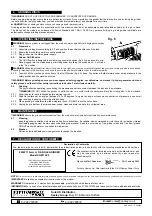

Grinder On/Off Switch

The On/Off switch is designed to avoid starting should the switch (fig. 6.A) be pressed in error.

5.2.1. Once plugged into the mains supply, start the grinder by sliding the switch back - it will latch

in the On position.

p

p

WARNING!

When the grinder first starts it will kick to the right, you must ensure therefore that the tool is securely gripped in both hands.

Especially important is the position you choose to secure the auxiliary handle in order to maintain stability.

5.2.2. To switch off the machine push the front of the On/Off button (fig. 6.A) down. The button will slide forward under spring pressure to the

safety position and the machine will stop.

p

WARNING!

Before grinding ensure you wear approved safety goggles, ear defenders, dust mask if grinder generates dust and

safety gloves, and that all other safety instructions in Section 1 are followed carefully.

5.3.

Grinding

The key to effective operating is controlling the pressure and surface contact between the disc and the workpiece.

p

WARNING!

DO NOT switch the grinder on whilst the disc is in contact with the workpiece. Bring the rotating disc to the workpiece.

5.3.1. Allow the disc to reach full speed before starting to grind.

5.3.2. Grind flat surfaces at an angle of between 10 to 20 degrees. Too great an angle will cause a concentration of pressure in one small

area resulting in gouging or burning of the surface.

5.3.3. When grinding is complete allow the workpiece to cool. DO NOT touch the hot surface.

5.3.4. Unplug the grinder from the mains power supply, clean and store in a safe, dry, childproof area.

5. OPERATING INSTRUCTIONS

p

WARNING!

DO NOT USE DISCS THAT ARE DAMAGED, OR SUSPECTED OF DAMAGE.

Before using a grinding disc ensure there are no fissures or cracks. Once mounted on the grinder test the disc before use by facing the grinder

in a safe direction (pointing away from yourself, others and vulnerable items) and operate for a short time.

s

DANGER!

Use of damaged discs may cause damage and/or personal injury.

Grinding and cutting discs used in association with this machine shall be of an adequate speed rating and suitable for the job in hand.

The discs shall be made in accordance with British Standard 4481:Part 1 1989. Only persons holding a grinding wheel certificate are

authorised to change grinding discs and wheels.

4. GRINDING DISCS

fig. 6

Declaration of Conformity

We, the sole importer into the UK, declare that the product listed below is in conformity with the following standards and directives.

The construction file for this product is held by the Manufacturer and

may be inspected, by a national authority, upon request to

Jack Sealey Ltd.

For Jack Sealey Ltd. Sole importer into the UK of Sealey Power Tools.

28th February 2005

800W 115mm H. D. ANGLE GRINDER

Model SGE115.V2

73/23/EEC Low Voltage Directive

89/336/EEC EMC Directive

98/37/EC Machinery Directive

93/68/EEC CE Marking Directive

6. MAINTENANCE

7. DECLARATION OF CONFORMITY

Signed by Mark Sweetman

SGE115.V2 - 2 - 280205