8

DO NOT

hold unsecured work in your hand and

DO NOT

touch the grinding disc whilst operating, or whilst plugged into the mains power.

8

DO NOT

leave the grinder running unattended, and

DO NOT

lay the grinder down whilst it is running.

8

DO NOT

operate the grinder when you are tired or under the influence of alcohol, drugs or intoxicating medication.

9

When not in use switch off grinder, remove plug from power supply and store in safe, dry, childproof area.

2. INTRODUCTION

Angle grinder with alloy drive casing and composite motor housing. Smooth running motor and bevel gears give low operating noise and

vibration. Models feature an integral spindle lock for fast loading/unloading of grinding discs. Slider type power control with power lock.

Supplied with side handle, guard and spanner. Grinding disc not included, order model no. PTC/115G.

3. SPECIFICATION

Model no: .................................................................

S0530.V2

Disc size: ..................................................................

Ø115mm

Spindle size: .........................................................

M14 x 2mm

Motor power: ...................................................................

600W

Supply: .............................................................................

230V

No load speed:.........................................................

11000rpm

N

ett Weight:

....................................................................

2.1kg

Noise power: ..................................................................

100dB

Noise pressure:................................................................

89dB

V

ibration: .................................................................

4.646m/s²

U

ncertainty: .................................................................

1.5m/s²

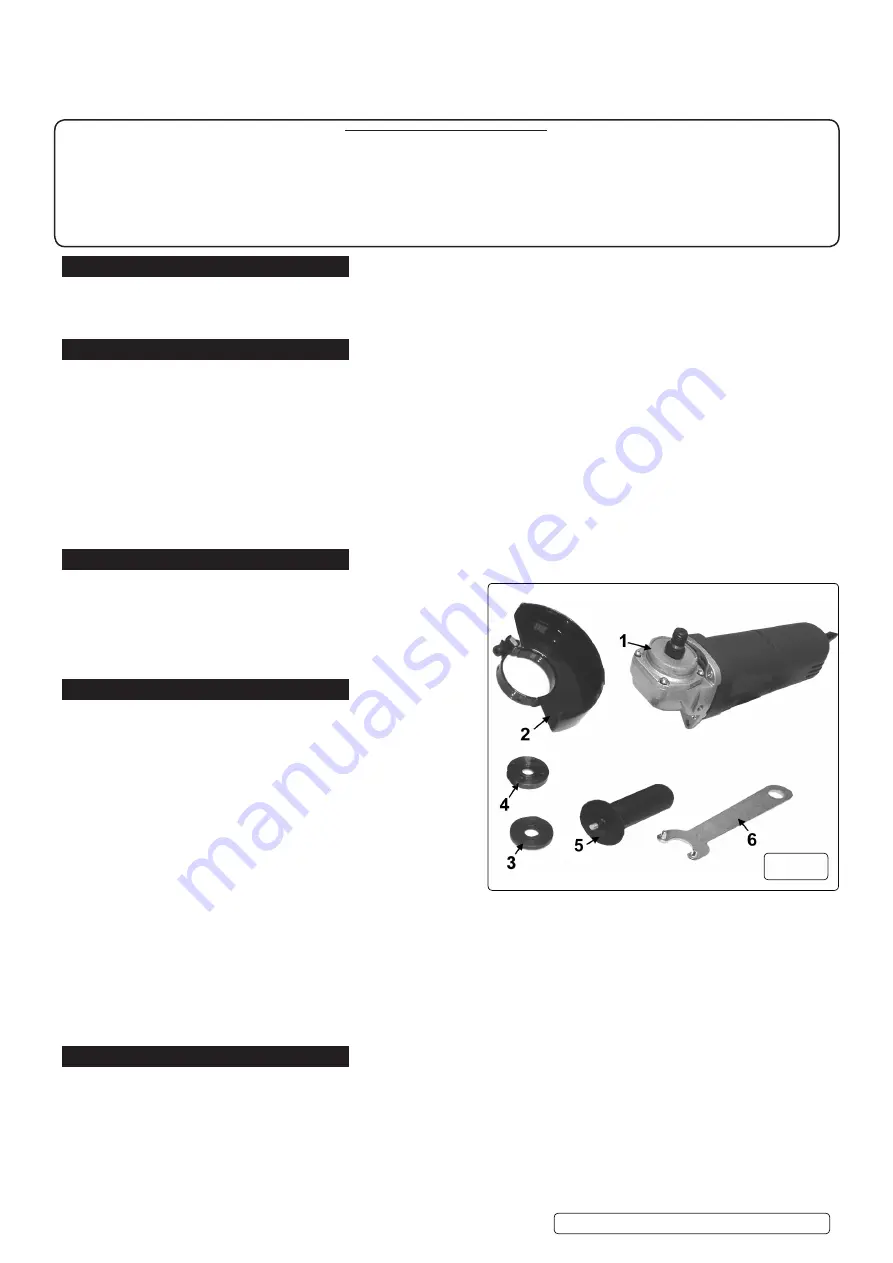

4. CONTENTS

1.

Angle grinder

2.

Safety guard

3.

Disc flange

4.

Nut flange

5.

Auxiliary handle

6. Disc spanner

5. ASSEMBLY

WARNING!

Ensure that the grinder is unplugged from the mains

power supply before assembling.

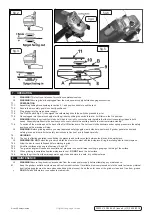

5.1.

FIT GRINDING DISC

(only to be performed by person holding grinding wheel certificate)

5.1.1.

Place the disc flange (fig.5.8)

onto the centre spindle (fig.5.A)

ensuring that the joint

ring (fig.5.9) is facing away from the grinder.

5.1.2.

Engage the recess in the disc flange with the drive flats on the shaft.

5.1.3.

Place grinding disc on the spindle.

5.1.4.

Retain disc with nut flange. Fit with spigot facing out if disc is less

than 5m

m thick, and facing in if disc is more than 5mm thick (fig.2 & 3).

5.1.5.

Stop the spindle from turning by pushing in and holding the

locking button (fig.4).

5.1.6.

Lock the grinding disc into place by tightening the nut flange (

fig.5.10) with the disc spanner (fig.5.11).

5.1.7.

Release the locking button and check that it has sprung back to the initial position.

5.2.

POSITIONING THE GUARD

5.2.1.

The guard may be rotated through any angle to suit the task.

5.2.2.

Position the guard to give working access whilst still providing maximum protection for the operator.

5.2.3.

Lock the guard in place by tightening locking bolt

(fig.4).

5.3.

HANDLE

5.3.1.

The auxiliary handle will allow better control and safety.

5.3.2.

Fit the handle by screwing it into the

threaded hole on either the left or right side of the gear box, as best suits the work.

6. GRINDING DISCS

WARNING! DO NOT USE DISCS THAT ARE DAMAGED, OR SUSPECTED OF DAMAGE

.

Before using a grinding disc ensure there are no fissures or cracks. Once mounted on the grinde

r test the disc before use by facing the

grinder in a safe direction (pointing away from yourself, others and vulnerable items) and operate for a short time.

▲

DANGER!

Use of damaged discs may cause damage and/or personal injury.

Grinding and cutting discs used in association with this machine shall be of an adequate speed rating and suitable for the job

in hand.

The discs should be manufactured in accordance with British Standard 4481:Part 1 1989.

Only persons holding a grinding wheel certificate are authorised to change grinding discs.

S

0530.V2, S0685.V2 | Issue 4 (H,F) 24/10/2018

Original Language Version

© Jack Sealey Limited

DANGER OF FIRE/EXPLOSION HAZARD

WARNING! The grinding process can produce streams of sparks which are a potential source of ignition, especially when

grinding metal.

8

DO NOT use the grinder where there are flammable liquids, solids or gases.

8

DO NOT allow grinder sparks to make contact with the operator’s clothing or any other fabric such as cleaning rags. Fabrics

contaminated with flammable materials such as petrol, oil, grease, paint and solvents are a particular fire hazard.

9

To reduce the risk of clothing catching fire the operator should wear wool or cotton outer garments treated with a fire retardant in

preference to man-made fibres.

Model no: ...............................................................

S0685.V2

Disc size:.................................................................

Ø115mm

Spindle size: ........................................................

M14 x 2mm

Motor power: .................................................................

860W

Supply: ...........................................................................

230V

No load speed: .......................................................

11000rpm

N

ett Weight:

..................................................................

2.3kg

Noise power: ................................................................

100dB

Noise pressure: ..............................................................

89dB

V

ibration: ................................................................

4.646m/s²

U

ncertainty: ................................................................

1.5m/s²

fig.1